The Future of Automobile Manufacturing

February 1, 2021 2:54 pm

Industry’s leading automobile predict digitalisation and democratisation of technologies along with monetisation of data will carve a bright future of India’s automobile sector in the near future.

The global automotive industry is undergoing significant disruptions across the value chain. Commercial Vehicles are expected to dominate by 2030 and passenger vehicles are projected to make just 5.08 percent of the market by 2030. With the increasing demand and adoption of E-mobility across the world, we foresee the future of Indian mobility to be clean and sustainable. The world economic forum highlighted that Indian automobile industry is one the fastest growing markets globally; still it makes only 0.5 percent in the global EV market.

Mobility when shared, connected, reliable, and electric would be clean; and Indian government is spurring actions to drive the adoption of clean transition, and has set a target of electrifying almost 30 percent of the vehicles by 2030, powered through electrifying passenger vehicles and commercial vehicles.

Industry’s reaction towards democratisation of technologies?

When we talk about manufacturing technologies, many people are actually expecting value-added services from the suppliers. And that’s where we really see huge increase from quite a lot of Tier-I suppliers are coming from India. Shree Harsha, Marketing Director – India, DassaultSystemes Ltd., says “If you look closely, all the digital technologies and the digital systems are available in India. We at Dassault, are working closely with quite a lot of OEMs across India and in some of the major foreign countries. Global companies are investing in and in our technologies because they consider it to be once in a lifetime opportunity for India to grab a considerably huge potential market share as part and process to shift them from China. And this is not only catering the Indian domestic OEM ecosystem, which is grappling with the supply chain disruptions, but also creates a sea of global opportunities. Even the western world and other global companies are willing to relocate the supply chain from China to India. We are also looking at a shifting the supply chain to India. So, I believe that we are on the cusp of a new transformation and we are right there serving this particular system. we will be happy to partner with anyone who want to really increase their value addition to the OEM ecosystem as well.

Dealing with supply-chain disruptions amid pandemic

According to Krishna Bhojkar, Head – Manufacturing, Skoda Auto, Volkawagen, “The supply chain disruptions are happening across the world and it needs a huge amount of change in the plants as well. Because we have no doubt towards the water production plants as it had to be realigned as per the availability of components. As a manufacturing group, we had to understand the same; and because of the same we still do components for Europe, South Africa or South America among other countries.

The most important thing is to have flexibility in terms of the production plans. We must comprehend and address the entire supply chain issues, especially in terms of transportation also. One of the most critical part was that our entire logistics people and our production planning guys has to invest huge amount of efforts to ensure smooth transit towards an entirely new plan. So, the entire process was planned in a way where every week some or the other things will be changes o transformed. And since we have done a lot of localisation already, this will be of great help for us in the long run.

Possibility towards battery re-cycling

The government and the world has been actively promoting EV, says Shikhar Gupta, Assistant Director – Power and Mobility, EY India. Before the battery recycling happens, there is a second life of batteries. And the most interesting factor is there are couple of energy companies that are already undertaking collaborations. For instance, let’s say hypothetically, batteries no more relevant for a car, it can be used at a substation level by a discount distribution company that will help them reduce their maintenance and infrastructure upgrades; which means you have extended the battery’s life-cycle. Eventually, battery recycling is a capital-in tensive thing. But again, under the Make in India initiative, and strong manufacturing capabilities of India, I believe India can soon become a hub for battery recycling. Moreover, you can actually harvest the raw materials, rare metals and maybe potentially sell it to life sciences companies, which can which can use them right. Iron, nickel and cobalt and several other things. So, we are positive towards battery recycling, but again we need a momentum in policy forms and it has to be insured.

Adoption of innovative technologies and increasing local content for manufacturing

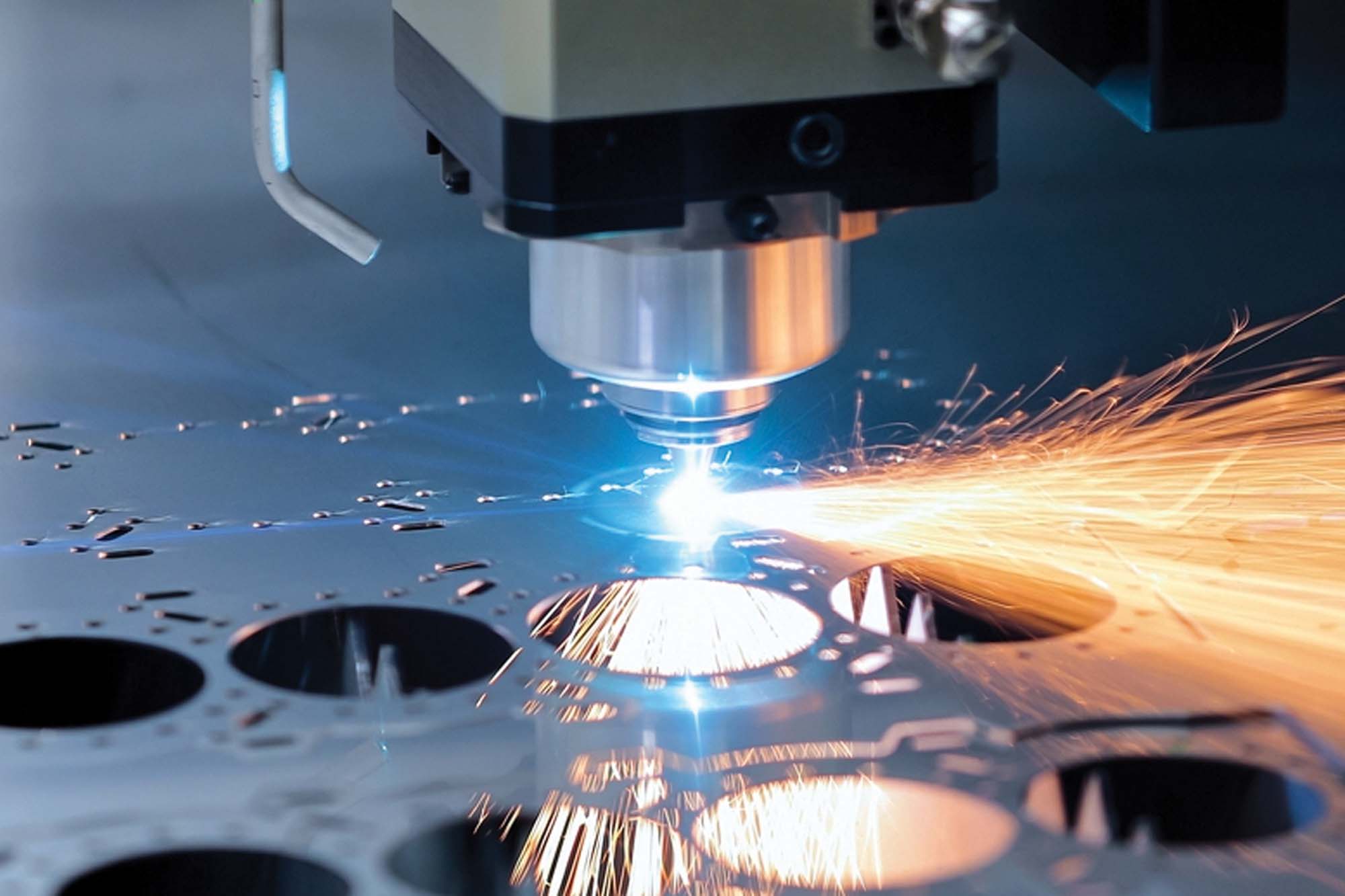

Shree Harsha, Director, Marketing – India, DassaultSystemes – Let me give you an example; Maruti Suzuki has more than 450 suppliers associate with them. They have been doing localisation for the parts and design products coming from Japan and have been doing localisation in India as well. So,when any OEM ask you to develop the particular product for a certain price volume, there are two kinds of business model they expect; one is built to print. They give you the specification and asked you to say give parts worth ₹ 2 Lakhs as that’s the primary purpose.

Secondly, it’s important to maintain a healthy relationship in businesses. If we have to give you the bar at six technology, so there are ample of suppliers in Tier-I and Tier-II where we are looking at a new exhaust manifold that can cut down the emissions to certain percentile. It’s not the Forte of OEM to look at carbon emissions and what kind of catalytic converter or any other technology can be involved to really put that product in place for the OEM as well. That’s more of a partnership approach. So, if you say ₹ 2 Lakhs is an additional cost burden for the OEM for introducing a BS6 exhaust emission related technology, OEMs will come back and ask the suppliers that can you make this whole particular component in ₹60,000 because of the costings; here, technology has to play the key role, as you will be modelling these technologies and test them for more than 1000 times to validate them with the OEM’s specifications within 14 months. There are no alternatives to these kind of virtual technologies. If you do it in traditional way, you design it and approach a workshop to cut the parts, and then you do testing. And, to be specific, this kind of partnership towards validation and evaluation has been there in the market for a very long time.

There is a common belief that technology like virtual twins are going to be financially feasible, if you have large scale manufacturing

Harsha finds this as a valid point. “It depends on the product type you’re making. So if you’re actually looking at an exhaust manifold, or a new injection technology altogether, or a component that comes with the new electric vehicle motor altogether. Then technology requirement become a mandate with no other alternative to fill in for it. If still you don’t infest these technologies, you will have to invest ages to really create that electric motor and you can never be able to become a supply chain leader.

So, to be more precise and specific, to be in the race and to become a supply chain expert it is an onus to apply digital technologies to the processes. Implement the digitalisation to your process and compare the ROI. I believe, you need to look at the entire value chain and say, this is where we are the cost structure critical element and here digitisation can be of great help.

If you ask me the pricing advantage, companies have more than ₹500 Cr spending on testing, and we were able to make a percentage reduction in that particular testing costs. Same thing is applicable in the supply chain as well. It’s about the cost advantage, or the business advantage. For many of the supply chain if the goal in that particular direction.

Krishna on the other hand, explains the benefits of digitisation. “We are trying to look at the possible ways to assemble all the plants together, and for the same we have collaborated with Amazon Web Services to create our own industrial cloud, where all the 122 plants will be connected. We have a plant of size of 1,80,000. So, if you are able to understand each other, and the entire operations, efficient ways of working, its measure, its benefits, it becomes easy to connect, maintain and perform well. So, technology is going to be an enabler for us in terms of harnessing our knowledge, and utilising it efficiently and effectively.

Also, the additive manufacturing is going to be a big thing as it let us design the process in an entirely different way when the parts which we thought were not meant for manufacturing, but could be manufactured using data; thereby reducing the cost itself. The only challenge right now being able to fit it in the cycle-time; because additive manufacturing is necessarily going to take a huge time right now. Although there have been huge changes in terms of the technology and how fast you can print. However, this is something which we are driving to see the possibilities to embed 3D manufacturing or the additive manufacturing on our manufacturing lines. Also, we are trying to see how this visibility can work for us. We can restrict the additive manufacturing to certain volumes, no doubt, but maybe it is possible still, so we still can try to make the most of the technology. Industry 4.0 is the same concept where you have huge amount of technologies available, you need to filter and pick the best suited for your requirement. I think technology is the way forward.

Emerging business opportunities in automobile sector

Shikhar, The automotive as a sector has transformed from a product-based industry to services-based industry, and I believe that’s another big area where a lot of new business models are emerging. If you look at there are so many opportunities like energy management, and OEM companies are awakened as a manufacturer. So the entire conversation around is not just about producing a vehicle, it’s also about how I can help you with leasing, financing, procurement, refurbish the batteries, and entire software part. All of it has an additional revenue models.

Even for EVs we need incessant innovations and financing models to ensure a rapid uptake. Here, OEMs can partner with the financial institutions, or battery manufacturers and start selling cars without batteries. It’s all about how do you monetise by adding infotainment and other customer services like data analytics.

Harsha agrees to what Shikharsaid He says “I think, monetisation of the data is a huge value added service as the amount of imagination that you can have either on insurance or well-being or on an additional service which consumer would expect. You can definitely implement the value added service on that particular service and club that as a part of OEM service. I think people are not really looking at that as a huge option.”

————————————————————————————-

To be in the race and to become a supply chain expert it is an onus to apply digital technologies to the processes.

Shree Harsha, Marketing Director – India, Dassault Systemes Ltd.

————————————————————————————-

As a service-based industry, India’s automobile sector is expected to create a sea of business opportunities in the coming years.

Shikhar Gupta, Assistant Director – Power and Mobility, EY India

————————————————————————————-

Technology is going to be an enabler for us in terms of harnessing our knowledge, and utilising it efficiently and effectively.

Krishna Bhojkar, Head – Manufacturing, Skoda Auto Volkswagen

————————————————————————————-

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.