Low-emission brake systems set to enter Eurozone car production

By Staff Report May 21, 2025 11:28 am IST

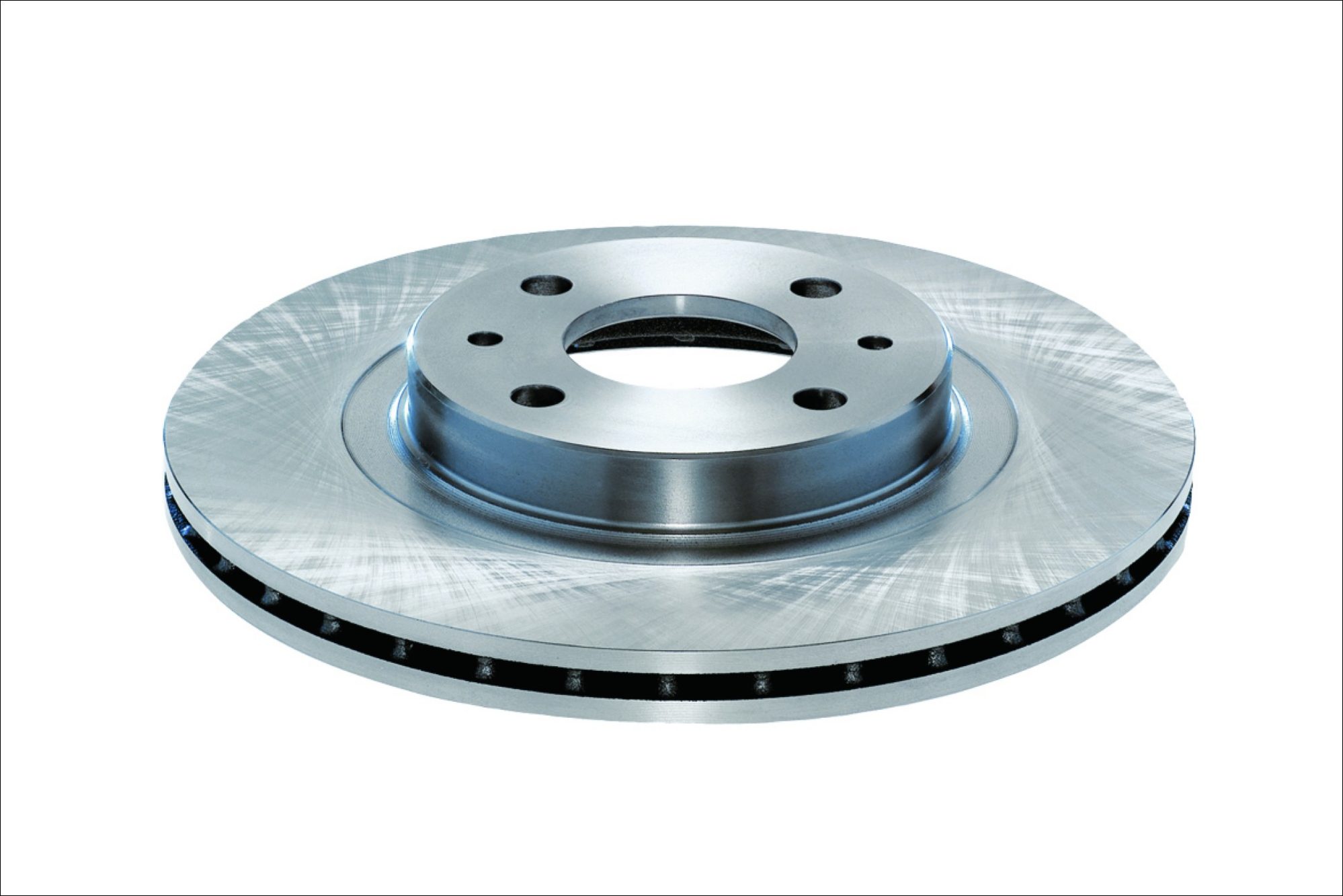

New car models in the Eurozone are set to be equipped with low-emission braking systems from next year, aiming to reduce particulate matter pollution in the transport sector. The first production lines for the new brake discs are currently being set up in the automotive industry.

In order to reduce particulate matter pollution in the Eurozone’s transport sector, new car models are to be equipped with low-emission braking systems from next year. For the manufacturing industry, this represents a technological leap that could only be achieved due to innovative materials and processes, new types of tools and machines and digital networking in production. This may ultimately benefit everyone, providing environmental and health protection through fewer fine dust particles in the atmosphere. The hard-coated brake disc favoured by European manufacturers is also more effective, corrosion-resistant and lasts the life of the car. This is why it was previously reserved for the luxury car segment.

The first production lines for the new brake discs are currently being set up in the automotive industry. In the case of hard-coated brake discs, this means that turned cast brake discs are processed by laser deposition welding or gas dynamic cold spray and subsequent double-sided surface grinding. While the first part of the process chain can still build on tried-and-tested methods, laser deposition welding with the subsequent grinding process differs significantly from previous methods.

Almost as hard as diamond

Modern carbides embedded in a metal matrix, which almost reach the hardness of diamonds, are decisive for this. The Fraunhofer Institute for Ceramic Technologies and Systems (IKTS) in Dresden explains how they are processed. Accordingly, the carbide metal powder is mixed using a customised powder nozzle system and applied to the rotating brake disc using a laser. Decisive cost advantages result from the process, the powder materials used and the low layer thicknesses that can be achieved, explains René Bischoff, Head of Development at IKTS’s technology partner C4 Laser Technology, which is also based in Dresden. In other words, a very thin layer can be applied by laser, which is extremely hard. This saves material and is considered extremely resource-efficient. However, the final grinding process is a major challenge.

High demands on tools and machines

The challenge became clear at the latest when the first newly coated brake discs were received by the grinding machine manufacturers for test trials: During the first tests, the grinding discs literally “tore apart” in the machine, it is said. This is because the previously completely unknown material mix of the top layer proved to be quite unimpressed by contact with the abrasive. The good news: The brake disc did what it was supposed to do. It developed a high braking effect without emitting fine dust particles.

“There’s nothing worse than not knowing exactly what needs to be ground,” emphasises Mario Preis, Head of Technology & Corporate Development at DVS Technology Group, Dietzenbach (Hesse).

As the various subsidiaries of the DVS Group, which specialises in surface processing, have specialists and suitable machine tools for each process step, this was followed by an intensive, cross-technology exchange. The aim was to develop a common understanding of the process and to find out which combination of coating, grinding wheel and motor spindle power would work best to achieve the desired geometry and surface properties of the brake discs.

Documentation for a safety-critical componentThe development and careful coordination along the process chain were not made any easier by the fact that there are also different variants and manufacturers of the new coating. In addition: “Even in the early stages of development, our customers wanted everything documented,” reports Mario Preis. After all, the brake disc is a safety-critical component for occupant and personal protection, which is subject to high-quality standards. What’s more, every vehicle manufacturer follows its own philosophy and has clear ideas about how the brake disc should look and how the vehicle should feel when braking. Preis is convinced that without digitalised process chains, it will hardly be possible to implement individual product specifications and changes as well as the constantly increasing documentation requirements economically. This is particularly true with regard to the EU CSRD (Corporate Sustainability Reporting Directive) on comprehensive sustainability reporting.

More flexibility thanks to digital networking

Irina Eisele, Lead IoT Product Development at the Emag Group, a machine tool manufacturer based in Salach (Baden-Württemberg), said, “Machine manufacturers are ahead of the game when it comes to digitalisation. Many machine tools are already equipped with extensive sensor and monitoring systems ex works. At the most recent grinding conference in Stuttgart-Fellbach, Eisele spoke about digital networking along the process chain using the example of hard-coated brake discs. The IoT (Internet of Things) specialist presented a holistic approach to workpiece-related recording and archiving of process data from various production steps and technologies. Whether production parameters such as laser power and powder feed rate, sensor data such as layer thicknesses and component geometry or process data such as grinding machine wear per workpiece. Data forms the basis for being able to optimise tools and process parameters in a targeted manner.”

Machine manufacturers support customers with hardware and software for data transfer and documentation. With the help of an industrial PC, machine controls and sensors are connected to the company network via suitable interfaces. The software collects the data, assigns it and analyses it. Workpiece-specific data can be recorded or visualised for documentation purposes, for example, to compare good and bad parts. “The clear added value for the user results from transparency,” emphasises Irina Eisele. The system view facilitates quality assurance and traceability. This is an invaluable advantage, especially for safety-critical components such as brake discs, where the processing history must be meticulously documented.

AI and DigitaliSation at EMO Hanover

The immense advantages of digital process chains inspire machine manufacturers and scientific institutes alike. It will also be reflected at EMO Hanover, the world’s leading trade fair for production technology, which the VDW (German Machine Tool Builders’ Association) is organising in the capital of Lower Saxony from 22 to 26 September. Companies will present best practice examples in a separate AI + Digitalisation Area. The spectrum ranges from smart production, Industry 4.0 and machine learning to the Internet of Things (IoT) and AI applications.

“We should rely more on data,” demands Irina Eisele. Digitisation simply makes it easier to understand which adjusting screws work and how. Users could react more quickly to product changes and new market requirements. In the case of the hard-coated brake disc, this should also prove particularly useful in the future. It is not only at Emag that brake discs for trucks and rail vehicles are next on the agenda. After all, nobody wants to stand in a fog of brake particles in train stations.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.