Additive process and recycling lead to a more sustainable manufacturing model

By OEM Update Editorial July 1, 2024 12:26 pm IST

Kuntesh Radadiya, General Manager at STPL3D, believes in the changing power of 3D printing technology. His vision extends beyond mere innovation; it encompasses revolutionising industries through rapid prototyping, encouraging enhanced customisation capabilities, and promoting a sustainable future where 3D printing emerges as a keystone of industrial practices.

How is the accessibility of 3D printing technology driving innovation and speeding up time-to-market for new products?

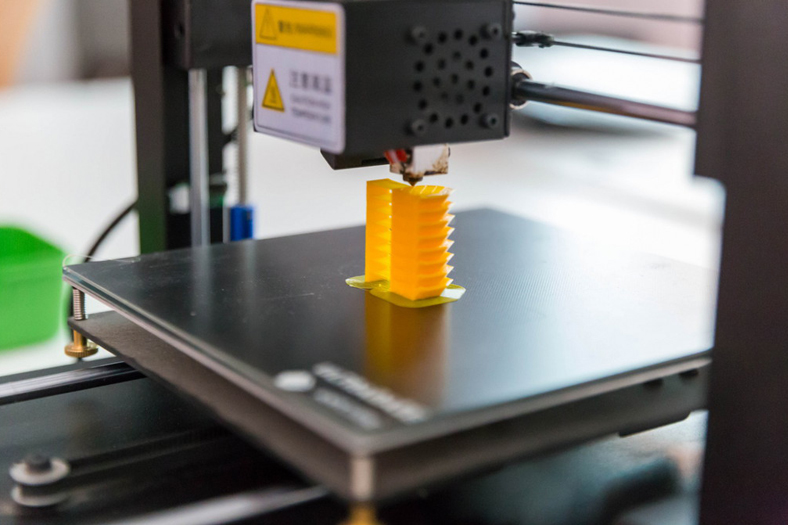

The 3D printing and prototyping market is experiencing substantial growth driven by increased awareness and a broader range of applications. Key drivers fuelling this growth include the demand for swift innovation and frequent product iterations, which 3D printing facilitates through its capacity to quickly and economically produce prototypes.

The accessibility of 3D printing technology has also improved, with advancements in speed and the variety of materials available, such as PLA, ABS, nylon, and metal composites. Moreover, the push for “Make in India” has made this technology more affordable and accessible, further propelling market growth. This technology accelerates the R&D process and significantly reduces the time and cost of bringing new products to market.

How is 3D printing influencing the automotive industry’s R&D and production efficiency?

3D printing technology impacts the automotive industry by enabling faster and more cost-effective R&D processes. It allows for rapid prototyping, which reduces the number of iterations required to perfect designs, thereby speeding up the innovation cycle. Automotive manufacturers can produce lightweight yet strong parts, enhancing vehicle performance with materials like PC, ABS, nylon, carbon fibre, aluminium, and stainless steel. The ability to produce large parts locally also reduces lead times and logistics costs. Overall, 3D printing technology cuts prototype costs by up to 70 percent compared to traditional methods, significantly reducing time-to-market and enabling more customised and innovative automotive solutions.

How does STPL 3D leverage collaboration with automotive manufacturers to enhance prototyping solutions and support rapid product development?

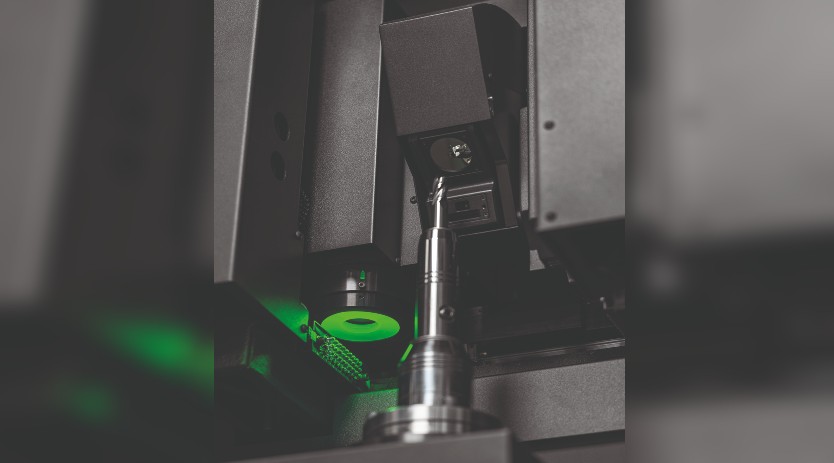

At STPL 3D, we collaborate with leading automotive manufacturers to provide comprehensive prototyping solutions using SLA, FDM, SLS, and metal 3D printing technologies. Our services include prototyping, injection moulding and vacuum casting to meet diverse manufacturing needs.

Moreover, we supply FDM, SLA, and SLS 3D printers for automotive R&D facilities, ensuring manufacturers possess the essential tools for rapid and efficient product development. Through customised solutions and cutting-edge 3D printing technology, we help automotive companies optimise production workflows, reduce costs, and accelerate innovation.How are additive manufacturing technologies enhancing product functionality and production efficiency across industries?

Additive manufacturing and prototyping techniques are poised for substantial evolution, broadening the spectrum of usable materials and incorporating smart materials capable of reacting to environmental stimuli.

These advancements will enhance the functionality of printed products. Improved printing technology will allow for greater precision and more intricate designs, benefiting high-precision industries like aerospace and medical devices. Innovations like multi-laser SLA and SLS printers will reduce printing times, making large-scale production more feasible. Additive manufacturing will become integral to production lines for on-demand manufacturing, reducing inventory needs and enabling rapid customisation. AI and machine learning will optimise designs, while enhanced simulation tools will allow for better virtual prototyping, saving time and resources.

How has 3D printing technology in manufacturing impacted product customisation and efficiency compared to traditional methods?

Manufacturers leverage 3D printing technology to streamline production by utilising rapid prototyping, which reduces the time and cost associated with traditional methods. This technology allows for the economical production of customised products, catering to individual customer needs without significant cost increases. The ability to create complex geometries opens up new possibilities in product design, leading to lighter, stronger, and more efficient parts. By integrating multiple functions into single parts, assembly time is reduced, and product reliability is improved. Overall, these advancements lead to more efficient and cost-effective manufacturing processes.

How do you envision the adoption of 3D printing technologies enhancing design flexibility and waste reduction?

The adoption of 3D printing technologies greatly enhances design flexibility and waste reduction. By optimising material use and structural integrity, 3D printing extends the lifespan of parts, reducing the frequency of replacements and waste generation. Many 3D printing materials are recyclable, and ongoing research is focused on developing biodegradable and sustainable materials. 3D printing supports on-demand production, reducing the potential for overproduction and waste associated with unsold products. Unlike traditional subtractive manufacturing, which carves out material from a solid block, 3D printing constructs objects layer by layer, using only the required material and significantly reducing waste. This additive process and recycling initiatives lead to a more sustainable manufacturing model.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.