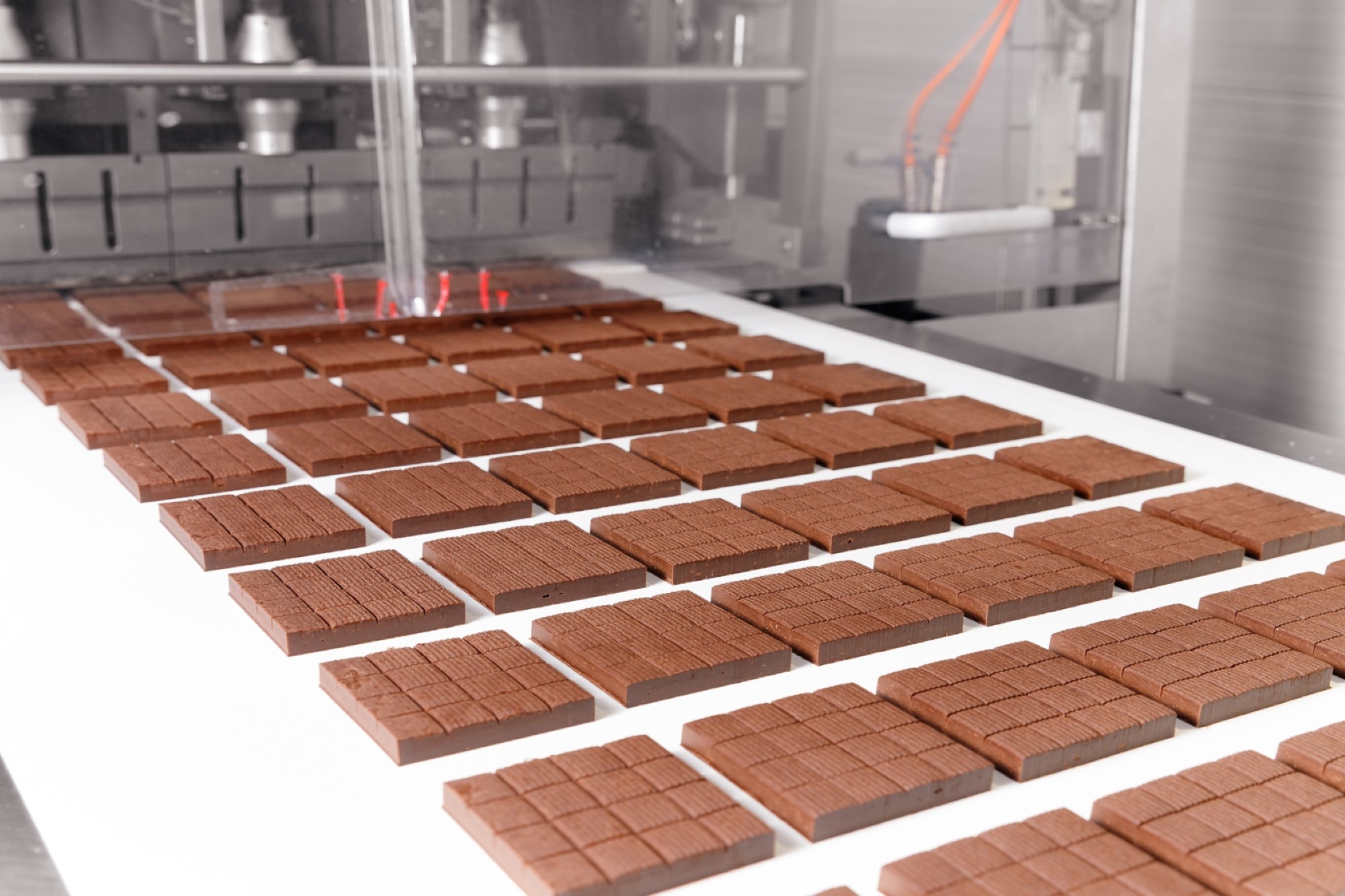

Need Fiscal Incentives to Promote Food Processing

By admin July 15, 2010 5:23 am IST

Jwala Engineering is a manufacturer of wide range of equipments for the Fruits and Vegetables Processing, Packaging and Material Handling. The Company also undertakes turnkey projects to set up complete plants for fruits and vegetable processing. Vimal Paharia, Director shares his opinion on various issues related to food processing machinery manufacturing industry.

Key issues and challenges faced by food processing machines manufacturers /customers

One of the biggest issues the food processing machinery manufacturers are facing is the small size of the food processing industry in India. The level of processing of food items in India is abysmal. For e.g. in India the amount of fruits and vegetables processed is only about 2%. In developed countries like US this figure is as high as 80%. Around 30% of the fruits and vegetables in India rot and are not usable due to lack of any processing. Hence there is an urgent need for the government to provide attractive incentives to encourage setting up of food processing units. Once the industry grows, then the prospects of food processing machinery manufacturers will also brighten.

Most food products are not excisable. But food processing machinery has an excise duty rate of 10.3%. The processors cannot Modvat the duty on machinery. This puts a significantly higher burden on the processor and hinders the expansion of existing plants and setting up of new plants. Hence Excise Duty on machines and equipments should not be levied as this directly increases the cost of the machines.

Technology used by food processors in India is not up to the global standards. The cost of development of new technologies is very high and hence we are reluctant to try out new things. Government should look at providing some incentives for manufacturers to develop new technologies indigenously.

Processors are reluctant to upgrade the machines and technology due to cost implications. Government should borrow the example of the Textile industry which has schemes like TUFS (Technology Upgradation Fund Scheme) that encourages people to upgrade their technology. A similar kind of scheme for the food processing industry is urgently required.

Government should grant fiscal incentives by way of higher percentage depreciation in assets like plant and machinery and other investments.

Major growth drivers

The food processing industry is growing at a good pace in the last few years. This has led to the growth of food processing machinery manufacturers as well. One of the major reasons has been increased acceptability of processed food by Indian consumers.

The Mega Food Parks set up by the government is a welcome initiative by the Ministry of Food Processing Industries (MoFPI). This has led to increased investments in food processing machines.

Future outlook

India is a vast country and the per capita income of Indians is increasing. More and more Indians, especially urban middle class people are now buying processed foods and it is no longer considered taboo to consume processed foods. This is leading to increasing demand of processed foods in India. This has raised the hopes of a bright future for food processing manufacturers and hence the machinery manufacturers in India.

The government is now increasingly realizing the importance of this sector in the Indian economy. The

MoFPI is actively working for the growth of the industry and is doing a commendable job. They have stated their goal to increase the level of processing of perishables to 20%. This should lead to corresponding increase in investments in this sector.

According to the Government of India, the total investment need in the food processing industry is Rs. 10 trillion. Even if a small fraction of that investment comes in, the food processing industry and hence the machinery manufacturing industry will see good days ahead.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.