Automating sustainably with Schmalz compact ejectors – SCPSc, and SCPSi

By Staff Report February 6, 2025 7:14 pm IST

In an era where sustainability is a global priority, industries are tasked with balancing operational efficiency and environmental responsibility. This challenge is particularly evident in manufacturing, where resource-intensive processes, such as using compressed air in automation, contribute significantly to energy consumption. Optimising these processes is essential to reduce environmental impact and achieve long-term cost savings. Schmalz has addressed this need by developing a series of compact ejectors , SCPSc and SCPSi , which combine cutting-edge technology with resource efficiency.

Sustainability as a design principle

Compressed air, though indispensable in vacuum systems, is often one of the most energy-intensive resources in automated operations. Recognising this, Schmalz has embedded air-saving technology into its ejector designs. This innovation optimises air usage, significantly reducing compressed air consumption by up to 80% compared to conventional systems. Beyond energy savings, this reduction lowers greenhouse gas emissions, supporting the global push toward sustainable manufacturing. Moreover, the SCPSc and SCPSi models incorporate durable materials and robust designs that extend their operational life. This minimises the frequency of replacements and reduces material waste, further contributing to sustainability goals.

Advancing automation with intelligent design

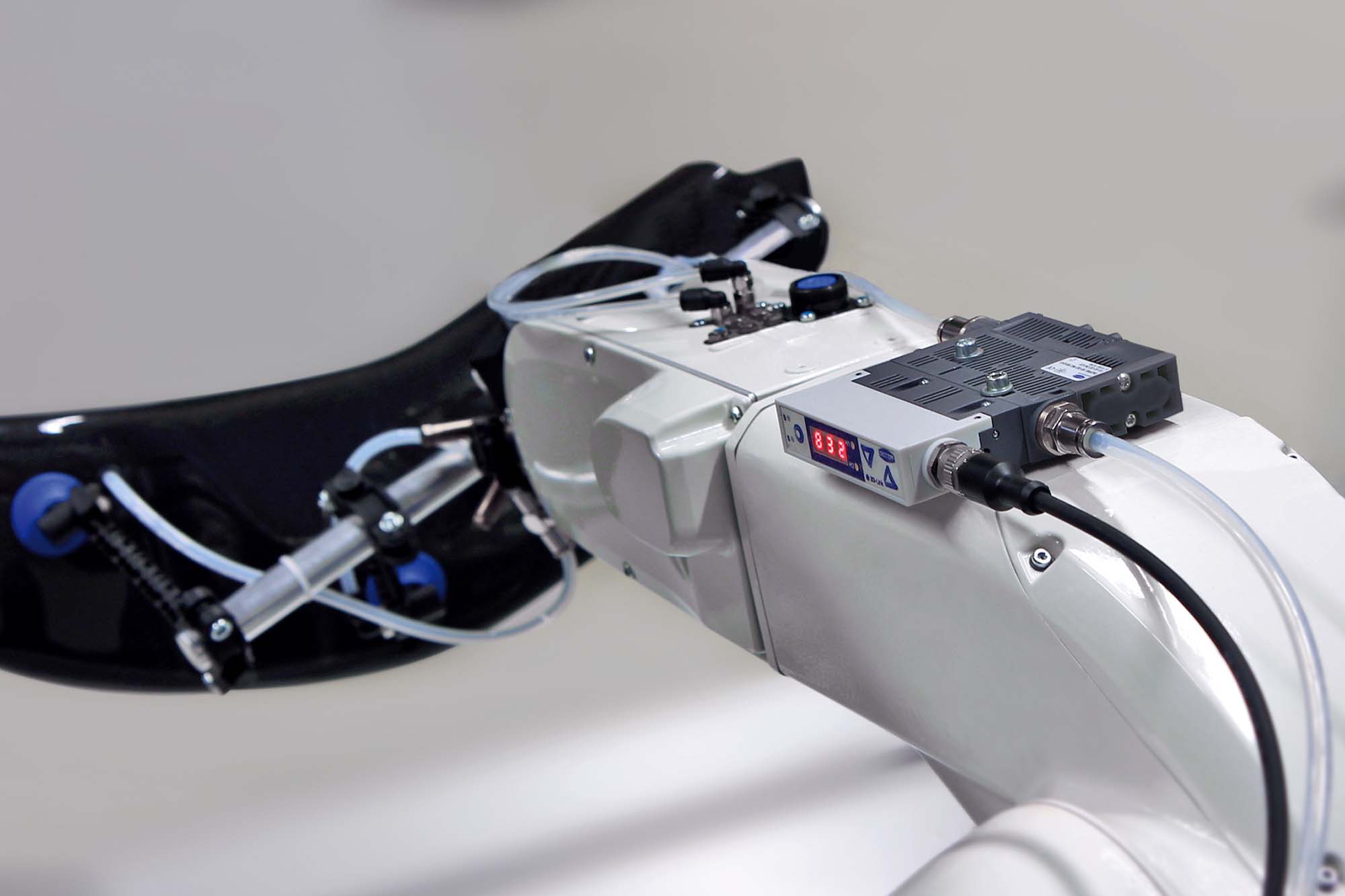

The compact ejectors are meticulously designed to meet the demands of modern automation. Their compact and lightweight construction allows seamless integration into automated systems, particularly in applications with limited space or high dynamics. The SCPS series offers fundamental reliability, while the SCPSc and SCPSi models bring advanced features tailored to specific industrial requirements.

The SCPSc model includes a user-friendly 7-segment display that provides clear, real-time information about system status and vacuum parameters. This ensures ease of operation and simplifies configuration, even in complex setups. The SCPSi variant takes this further by offering digital connectivity via IO-Link. This enables real-time monitoring of vacuum levels, energy consumption, and cycle times, allowing integration with Industry 4.0 systems.

(Images 2 & 3)

Applications across industries

Compact ejectors play a critical role in a variety of industrial applications. They are particularly suited for handling airtight and slightly porous workpieces, ensuring high precision and efficiency. Industries such as automotive, packaging, electronics, and logistics rely on these ejectors for diverse applications, including robot handling, pick-and-place operations, and linear axis systems.

For example, in the automotive industry, ejectors assist in lifting and positioning car body panels with optimised air consumption. Similarly, in packaging operations, they excel in handling lightweight and porous materials, such as cardboard, ensuring smooth and reliable processes. These versatile devices are indispensable wherever precision handling and energy efficiency are required.

Enhancing sustainability through air savingThe air-saving function integrated into SCPSc and SCPSi is a defining feature that sets these ejectors apart. By actively monitoring vacuum levels, the system ensures that compressed air is used only when necessary, preventing waste and reducing operational costs. This function is particularly impactful in high-cycle operations where air consumption can quickly escalate without proper control.

The SCPSi model’s advanced monitoring capabilities amplify these benefits. Its IO-Link interface facilitates seamless communication with automation systems, enabling users to track energy metrics in real time. This empowers businesses to make data-driven decisions, optimising their processes for efficiency and sustainability.

The intersection of technology and responsibility

Schmalz compact ejectors demonstrate how advanced engineering can contribute to sustainability goals. These ejectors improve operational efficiency and align with environmental objectives by minimising air consumption and integrating with modern digital systems. Manufacturers who choose these models benefit from a solution that enhances their operational performance and sustainability efforts.

Contact for questions

Schmalz India Private LimitedMarketing Department

EL 38, J Block, MIDC, Bhosari, Pune 411026

T: 020-69115500

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.