Filtering the future with finesse

By Staff Report May 7, 2025 6:44 pm IST

OEM Update team recently visited Fleetguard Filters’ Nandur facility near Pune to explore the remarkable journey of filtration technology — from conventional cloth and metal mesh filters to advanced synthetic media, polymer fibres, and nano nets. In this special feature, Mr. Vaibhav Pathak, Assistant Vice President – Operations, takes us through the cutting-edge manufacturing processes shaping the future of filtration. Also, don’t miss this video tour on our YouTube channel.

Fleetguard Filters Private Limited (FFPL) provides filtration solutions for on- and off-highway applications. It was established in 1987 in collaboration with Atmus Filtration (earlier Cummins Filtration U.S.A.), and

since then, it has grown to serve diverse markets and customers.

Fleetguard Filters has consistently innovated and excelled in the filtration industry. Headquartered in Baner, Pune, Fleetguard operates nine state-of-the-art manufacturing facilities strategically located in Dharwad, Jamshedpur, Hosur, Sitarganj, and Pune. This strategic placement ensures that they can promptly deliver products to their customers.

All the Fleetguard Filters manufacturing units are IATF-certified. In total, Fleetguard produces over 5,000 variants of advanced filtration solutions that cater to a wide range of industries, including automotive, agriculture, mining, and power generation, with plans to expand beyond these sectors.

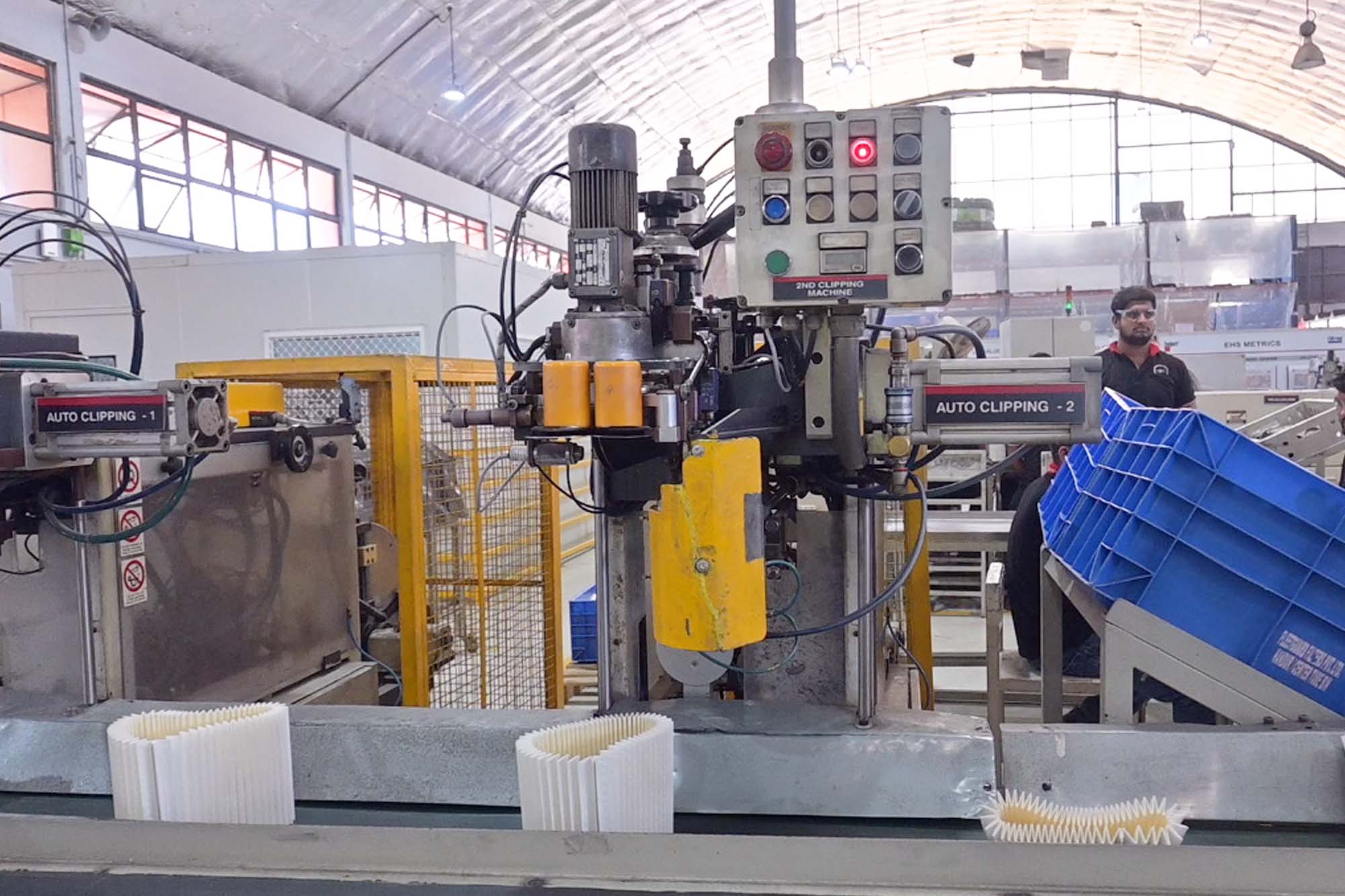

Technology is influencing right from communication to advanced manufacturing processes. It is very crucial to carefully choose technology appropriate to meet your customer’s requirements. At the Fleetguard Filters facility in Nandur, this principle was embraced. The plant has been designed to meet customer demands efficiently, ensuring 100% product availability and even during any fluctuations in demand meeting 100% quality expectations. It has a clean, well-organised layout with a balance of automation and skilled manpower.

Adopting AI, IoT, and digitising operations

The Internet of Things (IoT) has become essential for factories. Fleetguard Vaibhav Pathak Assistant Vice President – Operations Fleetguard Filters Filters has integrated AI to enhance the effectiveness of IoT beyond standard requirements. Since production began in the 1990s, the company recognised that upgrading every machine and analogue gauge to meet IoT demands was time consuming and costly. Instead, they adopted AI to convert analogue readings into digital data and capture them dynamically.

Fleetguard has implemented IoT across all production lines to create a paperless system. Fleetguard could also digitalize many AI inputs, which are otherwise not possible with traditional IOT. Such as validation by blue tests, roller gaps, etc. This approach helped them achieve full IoT integration while optimising cost and efficiency.

Fleetguard maintains a delivery rate of over 99%+ from five locations with nine plants. They have robust supply chain integration with over 100 OEM Customers and over 350 suppliers. Their capabilities include in-house design and analysis-led design (ALD), which allows for precision in development and performance.

As a direct result of implementing IoT in their operations, Fleetguard delivers flawless products and never receives a performance or quality defect. Each filter is manufactured to the highest quality standards.

Automation and robotics

Fleetguard carefully integrates technology by balancing labour costs with the benefits of automation. Before investing in each process, the company evaluates the applicability of seven levels of automation, aiming to implement at least level 5. At level 5, human involvement is limited to picking or placing items, while automation handles the rest. This strategy minimises gripper changeover time and optimally utilises human effort. Additionally, automation helps correct human errors, ensuring defects do not reach the customer.

While optimising capital expenditure, this approach also supports employment by preserving meaningful labour roles.

Upscaling initiatives with AI

At the Nandur facility, Fleetguard performs its operations rate at 1.66 seconds per component. Previously, operator training relied on visualisation tools to shorten training time. They now have AI to enhance this process through “action guidance” and “action recognition” systems. AI provides real-time instructions to operators, showing them where and how to carry out specific tasks.

In action guidance, the system highlights an exact area of action on the part and informs action to be performed. After the task is completed in “action recognition,” a camera verifies its correctness. This combination of action guidance and recognition minimises the need for extensive skills training. This allows operators to be assigned to any task with minimal preparation, thereby enhancing flexibility and efficiency on the shop floor.AI-based Knowledge Management and TOC Philosophy

By its model requirements, Fleetguard implements knowledge management practices alongside the Theory of Constraints (TOC).

Knowledge management is crucial for enhancing human skills and transferring knowledge. As employees retire or leave, valuable insights are lost. Also, knowledge is scattered across various sources such as documents, Excel sheets, machine manuals, and videos. To mitigate this issue, Fleetguard utilises an AI tool that aggregates information and makes it easily accessible. This ensures that valuable knowledge is never lost. This tool also translates content into multiple languages, helping the company overcome regional language barriers, especially since Fleetguard operates in five states.

Fleetguard adopted the TOC method in 2007, and it has since helped them serve over 100 OEMs with more than 5,000 Stock-Keeping Units (SKUs). In automotive manufacturing, each OEM product has about 5000 components. The final product cannot be completed if even one part is unavailable. By applying TOC principles, Fleetguard ensures 100% availability of all components. Fleetguard does not ask for forecasts from OEMs.

Fleetguard’s philosophy avoids dependence on forecasts, as they can be inaccurate. Instead, its TOC based system emphasises consumption-based data, which is most accurate. Specifically, focusing on what the customer consumed yesterday. This approach guarantees 100% accuracy.

In its TOC implementation, Fleetguard works backwards from customer consumption, using a pull-and-buffer system to manage urgency through a simple, colour-coded method. This system allows the company to effectively coordinate with 350 suppliers and manage 10,000 components, ensuring 100% delivery performance. Tools like dynamic buffer management allow them to adjust to fluctuations in customer volume without compromising inventory levels. This helps them to maintain inventory turnover and delivery performance.

Quality standards

To ensure that each filter meets the agreed DVPNR (Design Verification Plan and Report) or performance requirements, Fleetguard conducts a detailed analysis of the DVPNR. The company breaks it down to understand how specific manufacturing processes influence each requirement. Following the Six Sigma principle of Y = f(X1, X2, X3). X1, X2, and X3,….Xn are the inputs or controls. These are integrated into FMEAs (Failure Mode and Effects Analyses) and control plans to ensure they are monitored and maintained throughout production. Fleetguard also applies Poka Yoke principles— error-proofing techniques—especially in assembly, in all operations.

Sustainability

Sustainability is a key focus for Fleetguard, and the company has several environmental programs in place, ranging from reducing paper usage to optimising energy consumption. They are implementing solar energy projects across multiple plants, aiming to achieve net-zero emissions by 2045.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.