Continental aims for “zero carbon” by 2050

By OEM Update Editorial September 2, 2022 4:52 pm IST

Landry Tchapda, Head of Plant Management, Continental Surface Solutions India Pvt. Ltd., shares strategies and vivid details about the safety aspects, the shop floor, utilities and the plant activity.

Continental has been growing steadily in the Indian market. They have invested in Pune, a notable and established hub for the automotive industry. Continental develops pioneering technologies and services for sustainable and connected people’s and goods’ mobility. The company offer sefficient, intelligent, and affordable vehicles, machines, and transportation solutions. Continental has existed in India for nearly 50 years through technology partnerships and joint ventures for its various businesses. It aims to be its customers’ first partner of choice for surface solutions.

Production scaling

A wide range of quality surface solutions from Continental ensures a variety of options for interior combinations to attract car buyers. Compared to natur all eather, the company’s surface material products are durable, innovative, easy to maintain, and affordable. Continental Surface Solutions plant manufacturing facility at Pune has a spread area of 149,000sq. ft. with an initial annual capacity of five million square meters of surface material. This capacity can be scaled up to10 million square meters. Within vestments totaling about 2 billion Indian Rupee (more than 20 million Euro) covering facilities and machinery, Continental will produce premium surface materials for car interiors, including electric vehicles and two-wheeler seats, catering primarily to the domestic market and exports.

Plant and amenities

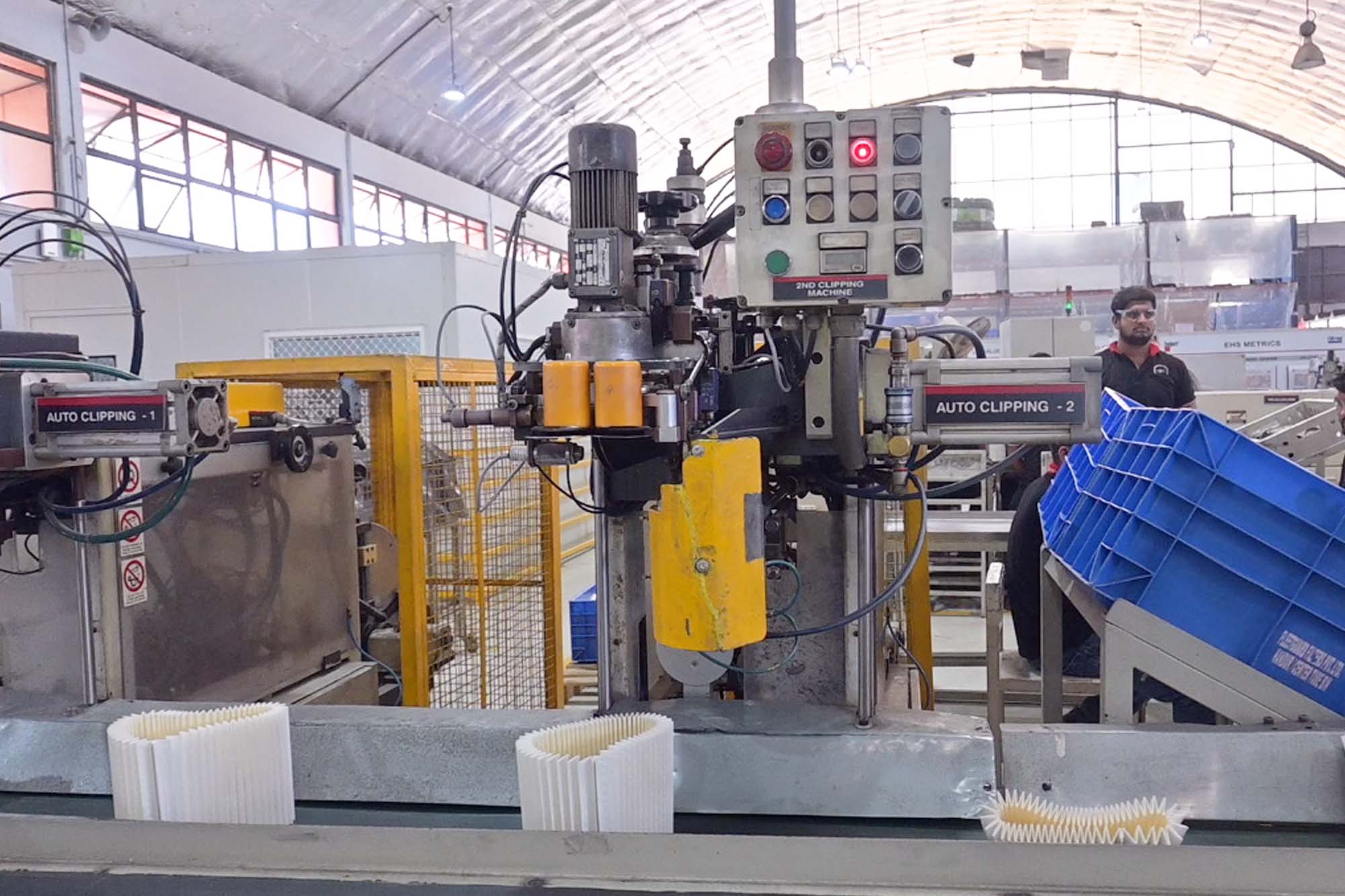

The new plant features best in-class energy efficiency standards, sustainable production processes, an ergonomic work environment,100 percent sewage and wastewater treatment, exhaust air treatment, and energy from renewable sources. In addition to production storage, logistics, purchasing, and sales; the plant includes offers resources and capacities for laboratories, design and product development. The new surface solutions plant in Pune primarily manufactures Acella Eco and Acella Lux materials, which add aesthetic value to vehicle interiors. Eco-friendly foam foil Yorn and Yorn Light will also be produced shortly. In 2021, Continental generated sales of €33.8 billion and currently employs more than190,000 people in 58 countries and markets. On October 8,2021, the company celebrated its 150th anniversary. Continental’s Surface Solutions greenfield plant in Pune manufactures surface solutions materials mainly for the Indian automotive sector which includes passenger car and two-wheeler market. Location in Pune is Continental’s sixteenth surface solutions plant globally. It produces well-known surface materials like Acella Eco used by top worldwide car manufacturers and automotive brands.

Investment capacityThey have invested approximately Rs. 200 Cr for the setup of the plant, the buildings, the utilities and the machines. “As far as the plant capacity is concerned, we can supply approximately 5 million square meters annually. And with our setup, we also have the flexibility to scale it up within the next few years. From the product perspective, we are currently extending our value chain investing in a perforation unit. This will help to support our customers in perforated and ventilated seats. We are in a tropical country wherein the summertime, it can be boiling in the cars. And with the ventilation, our perforated material helps to cooldown and to make the drive more comfortable. And depending on our success in the market we will do the necessary investments further.”

Bright future

“We at Continental have a target of decarbonisation by 2050. That means to be at zero. To say the least, zero litres of water are wasted or thrown away from this plant. Furthermore, almost all production processes are optimized with state of the art machineries. People and Safety is the number one priority for us. In the last three years of construction activity, no accidents were reported while setting up the plant. In today’s auto market, we see vehicles with high-quality interiors in peak demand. Also, Pune is one of the biggest automotive hubs in India. We have all the biggest OEMs here nearby, and we are charmed with the emerging growth prospects,” concludes Tchapda.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.