Atlas Copco launches Reman equipment program in India

By Staff Report May 14, 2025 4:33 pm IST

Atlas Copco introduces sustainable industrial solutions by introducing remanufactured equipment in India. This focuses on cost-efficiency and environmental responsibility in heavy machinery operations.

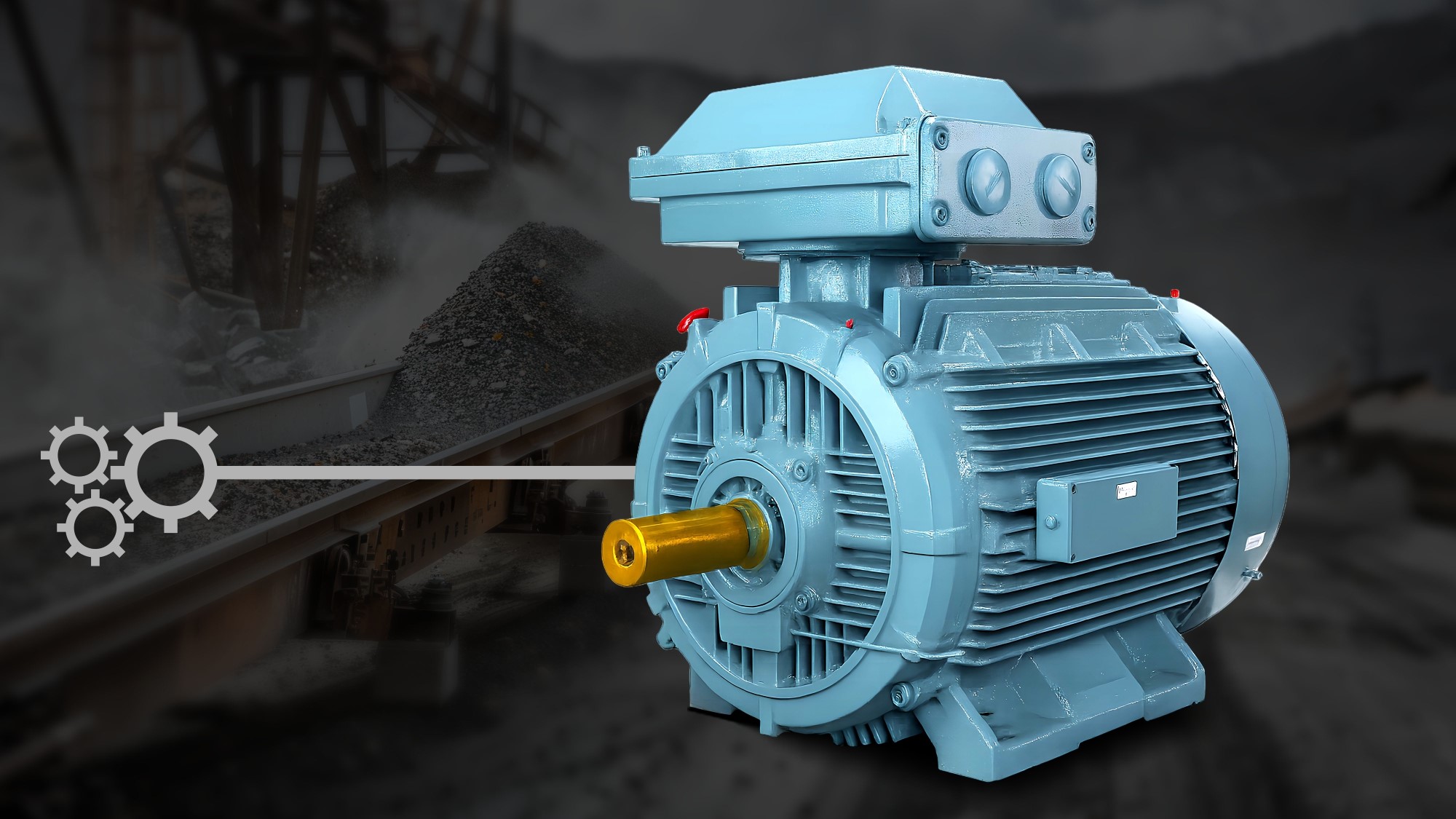

Atlas Copco launches Reman Equipment Programme in India, an initiative designed to restore used compressors and engines to their original performance standards. The main objective of the program is to extend the operational life of the equipment, reduce total cost of ownership, minimise environmental impact through sustainable practices and provide customers with reliable, high-quality refurbished equipment. The company delivered its first restored compressor under the programme and is ready to deliver customised, high-quality solutions to meet future industry needs.

This programme offers refurbished equipment that matches the performance of new units at a fraction of the cost. Customers benefit from significant savings as they do not have to purchase new equipment, reduced downtime with faster turnaround times, and access to upgraded technology and extended equipment lifespan with reliable performance. Industries such as construction, mining, water wells, oil, and gas will benefit from this initiative, with access to robust and dependable compressors designed to meet their specific operational demands.

The remanufacturing process involves:

• Assessment: Evaluating the condition of returned equipment

• Disassembly: Breaking down equipment into individual components

• Cleaning: Removing contaminants and residues

• Inspection: Checking parts for wear and damage

• Replacement: Substituting worn or damaged parts with new or refurbished ones

• Reassembly: Putting the equipment back together

• Testing: Conducting performance tests to ensure quality

• Painting and Finishing: Applying protective coatings and final touches

Atlas Copco provides warranties for remanufactured equipment, covering defects in design and production. It also ensures quality assurance by using genuine parts, skilled technicians, and strict adherence to ISO certifications.

Prasanna Kulkarni, General Manager, Power Technique Customer Centre, Atlas Copco (India) Pvt Ltd, stated, “The Reman Equipment Program represents a significant step in our commitment to sustainability, performance reliability, and customer value. By using existing components and materials, we reduce manufacturing costs and promote resource conservation.”

With a focus on reducing carbon footprint, promoting resource management, and environmental goals, the program supports energy efficiency, waste reduction, and the reuse of materials. Atlas Copco anticipates continued growth in the remanufactured equipment market, by rising demand for sustainable and cost-effective solutions. The company plans to expand its remanufacturing capabilities and continue investing in advanced technologies to meet evolving customer needs.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.