CoroDrill DE10: inside Sandvik Coromant next-gen drilling innovation

By Staff Report May 20, 2025 12:54 pm IST

Sandvik Coromant introduces a drilling portfolio with the launch of the CoroDrill DE10, developed in response to evolving manufacturing needs. The journey created a second-generation exchangeable-tip drill.

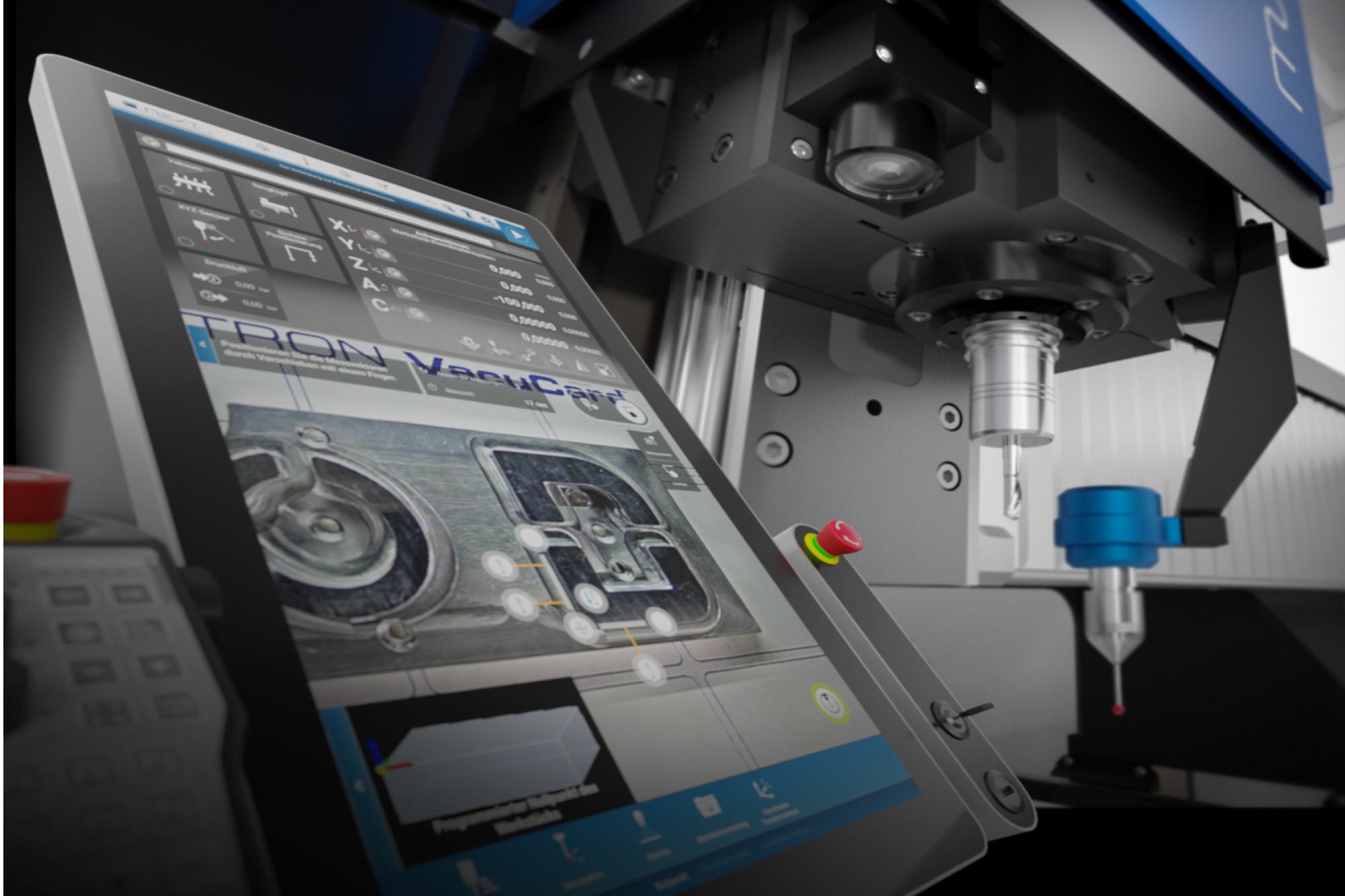

Sandvik Coromant introduced CoroDrill® DE10. Featuring universal M5 geometry and plug-and-play functionality, with no need for a pilot drill, CoroDrill® DE10 offers setup, performance, and versatility across a range of materials. Mikael Carlsson, Global Product Specialist for Indexable Rotating Tools at Sandvik Coromant, stated how customer needs and collaboration shaped the development of the second-generation exchangeable-tip drill.

The journey to CoroDrill® DE10 began with the launch of CoroDrill® 870, designed to improve drilling efficiency with an exchangeable-tip system. As customer demands evolved, there was a need in the market for reliability, longer tool life, and easier handling. In response, Sandvik Coromant launched a project to develop a drill that would deliver productivity, ease of use, and adaptability to meet manufacturing demands.

Designing a Plug-and-Play Solution

The skills gap is one of the difficulties in manufacturing. Operators need tools that are performing and easy to select, set up, and use. CoroDrill® DE10 was designed to allow operators of different skill levels to achieve results with minimal setup time.

The tool had to offer versatility to enable hole making across materials, including steel, stainless steel, heat-resistant superalloys, cast iron, non-ferrous materials, and hardened steel. It also needed to be durable to ensure tool life under cutting parameters.

Developing a tool capable of meeting industry needs required a structured approach to designing, testing, and manufacturing. At Sandvik Coromant, product development starts with conceptual designs, then transitions to in-house prototyping and lab testing, followed by customer trials. Keeping manufacturing and testing under one roof allowed the team to iterate through multiple feedback loops before finalising the design.

CoroDrill® DE10 features a steel drill body and a patented drill tip-to-body interface. Another feature is its injection-moulded drill tip — a first for Sandvik Coromant. Powder injection molding, a technique used for plastics, was adapted for solid carbide, allowing for a more detailed drill tip design. Once the centre of the drill tip had been refined for reliability and precision, the team reinforced the corners to improve performance and hole quality. The result is a drill tip that supports tool life and hole making across cutting parameters.

Embracing Adaptation

Developing CoroDrill® DE10 required refinement based on testing and customer feedback. The testing process began with a focus on durability and process security, as the team stress-tested the tool’s strength, longevity, and performance under various conditions. With this foundation established, they adjusted the drill’s geometry to optimise feed rates, reduce cutting forces, and enhance hole quality.

Manufacturing techniques, including the use of digital twins, played a role in refining the design. By simulating the drill’s performance in a virtual environment, the R&D team tested its limits to identify areas for improvement. Virtual testing also provided insights into the manufacturability of the design, ensuring the drill was scalable for production.

Customer insights were used throughout development, from the project’s conception to testing. Feedback from CoroDrill® 870 users shaped the foundation of CoroDrill® DE10, and field testing influenced refinements to address user-identified requirements and challenges.

Late in development, one addition was the plastic handle with a collar set for the drill tip mounting key. Every drill box includes a standard key usable across the assortment, a plastic handle for the mounting key is also available to order. During field testing, some users raised concerns about the safety and use of the key, leading the team to develop a plastic handle to improve handling and reduce the risk of carbide splinters.

Ulrik Sunnvius, Senior R&D Engineer at Sandvik Coromant, stated, “Customer feedback is crucial to our development process as it allows us to make real-world adjustments. This is why we created the plastic handle key — to provide operators with an option for handling and safety.”

Innovation Through Collaboration

The development process brought together specialists across disciplines. A Scandinavian work culture, where hierarchy allows dialogue, enabled the team to work together to create a drill that meets customer needs.

Sunnvius stated, “One of the enablers of our success is the way we collaborate; anyone can ask questions and contribute ideas. That flow of knowledge allows us to continue innovating.”

The development of CoroDrill® DE10 demonstrates the role of adaptability and collaboration. By combining design, testing, and user insights, Sandvik Coromant created a tool aligned with current manufacturing requirements.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.