India now manufactures PTFE liners for high-performance automotive control cables

By Staff Report June 18, 2025 11:29 am IST

Yash Dynamics Private Limited offers locally manufactured PTFE liners in India, reducing reliance on imports and offering high-quality, cost-effective solutions for automotive control cables in high-temperature, high-performance applications.

Automobile manufacturing is changing rapidly to meet the latest demands for luxury, safety, and long-lasting performance. Amenities like throttle, clutch brake systems, have become more standard.

PTFE liners allow the incorporation of these features into automotive control cables with greater efficiency and reliability. Both consumer demand and evolving markets drive the increased use of mechanical functions in cars. These advances require control cables to work harder at higher temperatures continuously for years. The use of control cables will continue to grow thanks to:

- Continuous advancements in vehicle features

- An expectation of comfort and ergonomics

- A drive toward longer warranties and decades of operational efficiency for system assemblies

In addition to vehicle components that are more futuristic and consumer-facing, new designs for fuel and braking systems, powertrains, chassis, and interiors also require high-performance cabling. Here, PTFE liners play key roles wherever cables need thinner but better and smoother liner materials that can withstand ever-increasing service temperatures.

Characteristics of PTFE liners that make them an excellent choice for automotive applications include:

- High/low-temperature resistance

- Chemical and hydrolysis resistance

- High dielectric properties

- Stress-crack resistance

- Dimensional stability

- Low permeability

- Low coefficient of friction

Indian market scenario

The present PTFE liners market for control cables is being served by limited international tube manufacturing companies, which makes any Indian automotive OEM company largely dependent on international sourcing, leaving them with:

- Undetermined priced purchases and import costs

- Import hassles

- Forex Fluctuations

- Ungoverned quality control

- Long delivery period

- Long-term stock planning

- Fund blocking

- Stringent availability

PTFE tube manufacturing challenges

Raw material sourcing presents a significant challenge. Most PTFE fine powder manufacturers worldwide already have technical support agreements with existing international PTFE tube manufacturers, leading to limitations in technical support, process expertise, equipment specifications, and more. Identifying candidates for raw material grades based on properties and standards for a specific application is also tricky for any PTFE tube manufacturer.

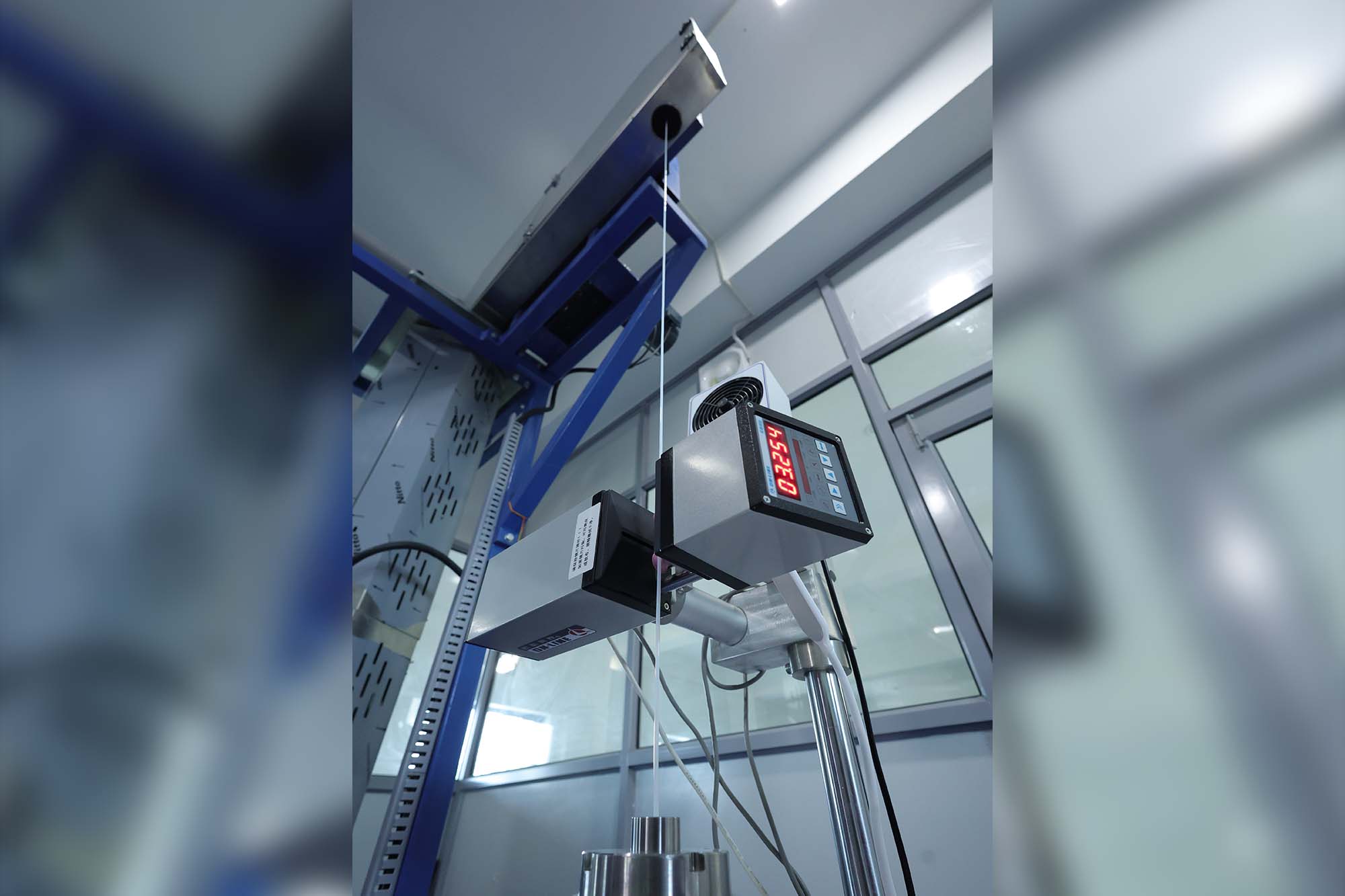

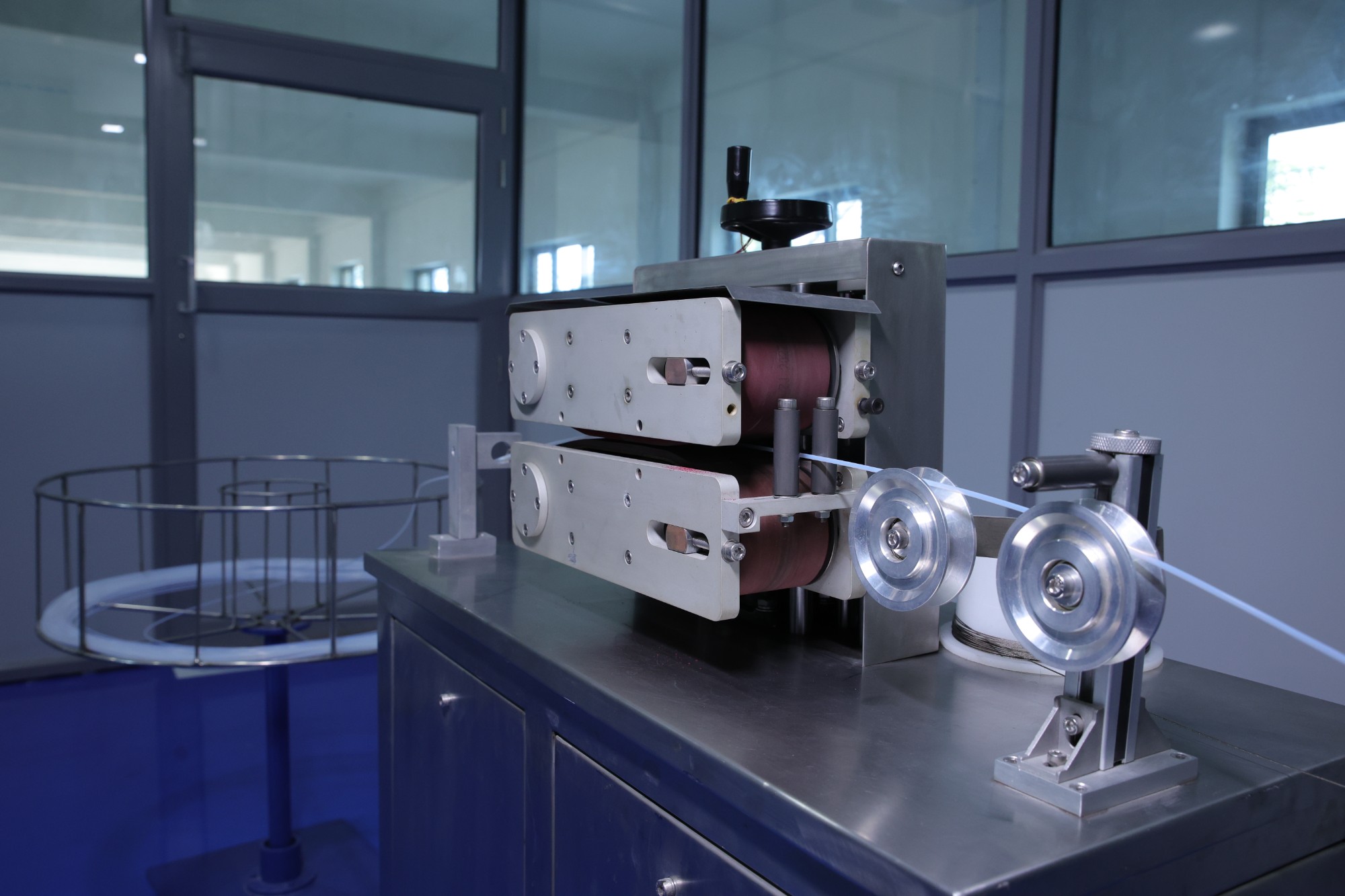

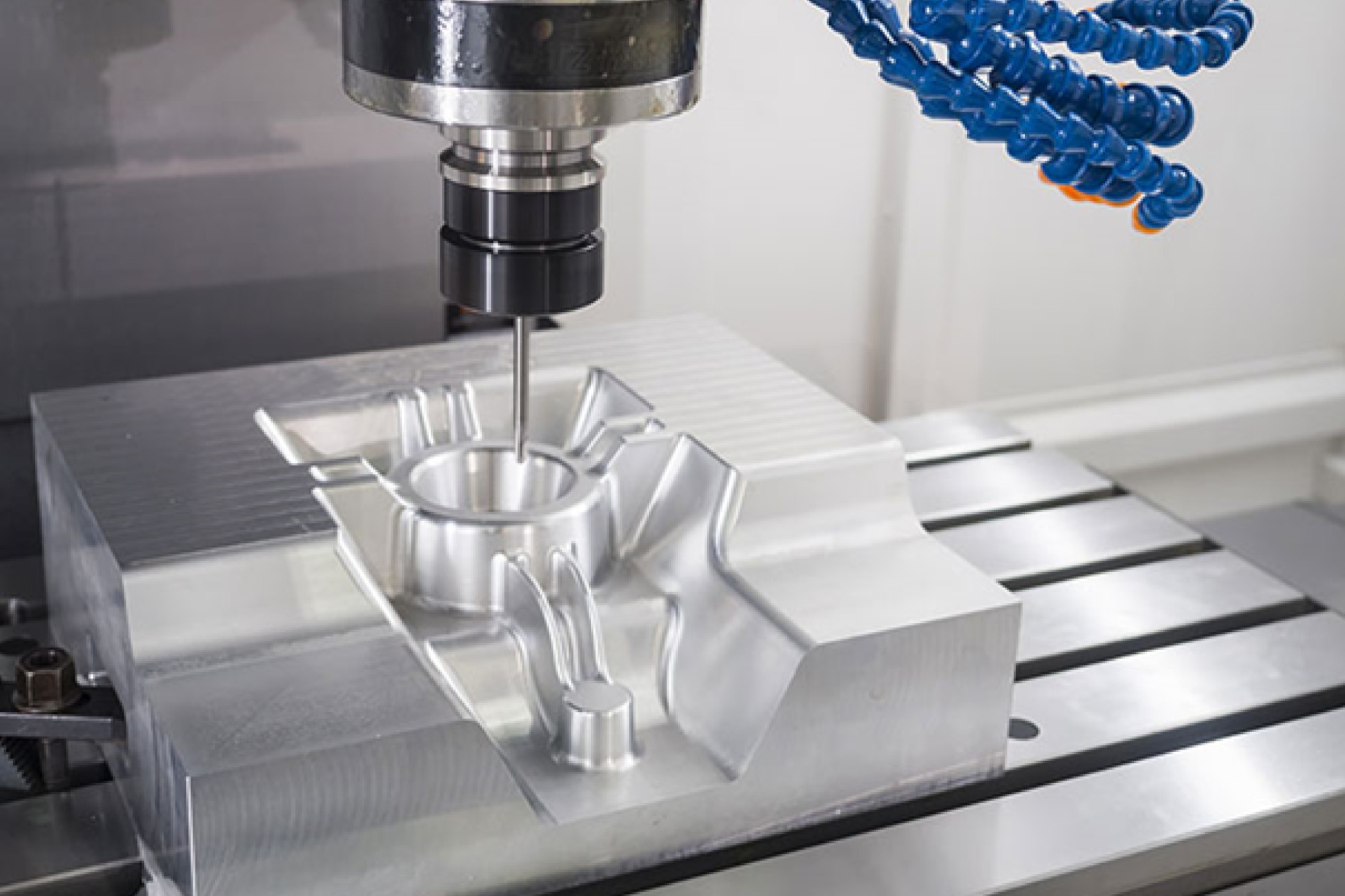

Manufacturing requirements are also a challenge. PTFE tubing demands strict quality parameters due to its application and tight tolerances. Key quality parameters of PTFE tubes are surface smoothness, ovality, tensile strength, elongation, concentricity, ID/OD maintenance, and long length for control cables. This makes the manufacturing technique and equipment highly complex.

Another major barrier to manufacturing PTFE tubes is that production technology is proprietary in nature, and machine lines are to be designed and developed jointly by PTFE tube manufacturers and raw material technical collaborators.

Yash Dynamics

Yash Dynamics Private Limited is an Indian company specializing in high-grade PTFE tubing and liners using advanced paste extrusion technology. Focusing on the Indian fluoropolymer industry, particularly for automotive OEMs, the company produces long-length PTFE extruded tubing at its facility in Dehradun, Uttarakhand, which includes a fully equipped quality assurance laboratory.

Currently operating two extrusion lines, Yash Dynamics plans to expand by adding two more lines each year. The company holds a technical agreement with India’s only PTFE fine powder manufacturer and offers a range of PTFE liners for various applications, including throttle and clutch cables etc. They provide prototype liners to automotive manufacturers before moving into larger production volumes.

Yash Dynamics has ISO 9001:2015 certification and uses high-quality PTFE fine powder to ensure durability and smooth operation. PTFE’s high melting point makes the products ideal for high-temperature environments, reducing issues like stiction commonly found in standard cables.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.