Single source for a full range of robotic and manual welding solutions

By Staff Report June 18, 2025 6:06 pm IST

CLOOS INDIA delivers a full range of robotic and manual welding solutions from a single source. They have been offering individual automation solutions for a wide range of industries, including construction and earthmoving, agriculture, mining, materials handling, hydraulic cylinders, transformers, and shipbuilding.

QINEO-Manual welding solution

Cloos India offers high-quality welding machines for manual and automated applications. The next-generation MIG/MAG welding power source is an excellent new technology for pulsed arc welding.

ArcBoT- Cobot welding solution

With the QINEO ArcBoT Welding System, users can weld small batch sizes economically and with high quality. The high-tech MIG/MAG welding power source and the precise ArcBoT work perfectly together.

The compact “Ready to weld” package is delivered completely ready for operation. This guarantees a problem-free integration into existing production processes. A torque sensor in each axis allows the ArcBoT to be programmed and moved precisely.

QIROX- Robotic welding solution

QIROX comprises all solutions for automated welding and cutting. Due to its modular design, the QIROX system allows scalable solutions to match production requirements. The QIROX system, which encompasses automatic welding and cutting robot technology, positioners, safety technology, software, sensors, and interfaces to process technology, is complemented by an extensive range of options and complementary services.

Inauguration

CLOOS INDIA opened a new facility in Chinchwad, Pune, on April 10th 2025, combining sales, service, design, R&D, training, experience centre, and stores under one roof, aiming to improve operational excellence and provide superior service and support to customers. This milestone reflects CLOOS INDIA’s commitment to advancing technology, strengthening customer relationships, and supporting the dynamic needs of the Indian manufacturing sector.

All from a single source

CLOOS Arc Seam Tracking without a laser ensures precise torch position monitoring of the programmed path during welding. This enables automated adjustment deviations for consistent, high-quality welding. Loss of time is minimised because measuring and welding take place simultaneously with the arc sensor. Workpiece distortion, such as thermal expansion, is directly compensated for. CLOOS arc sensor thus combines productivity with optimised quality.

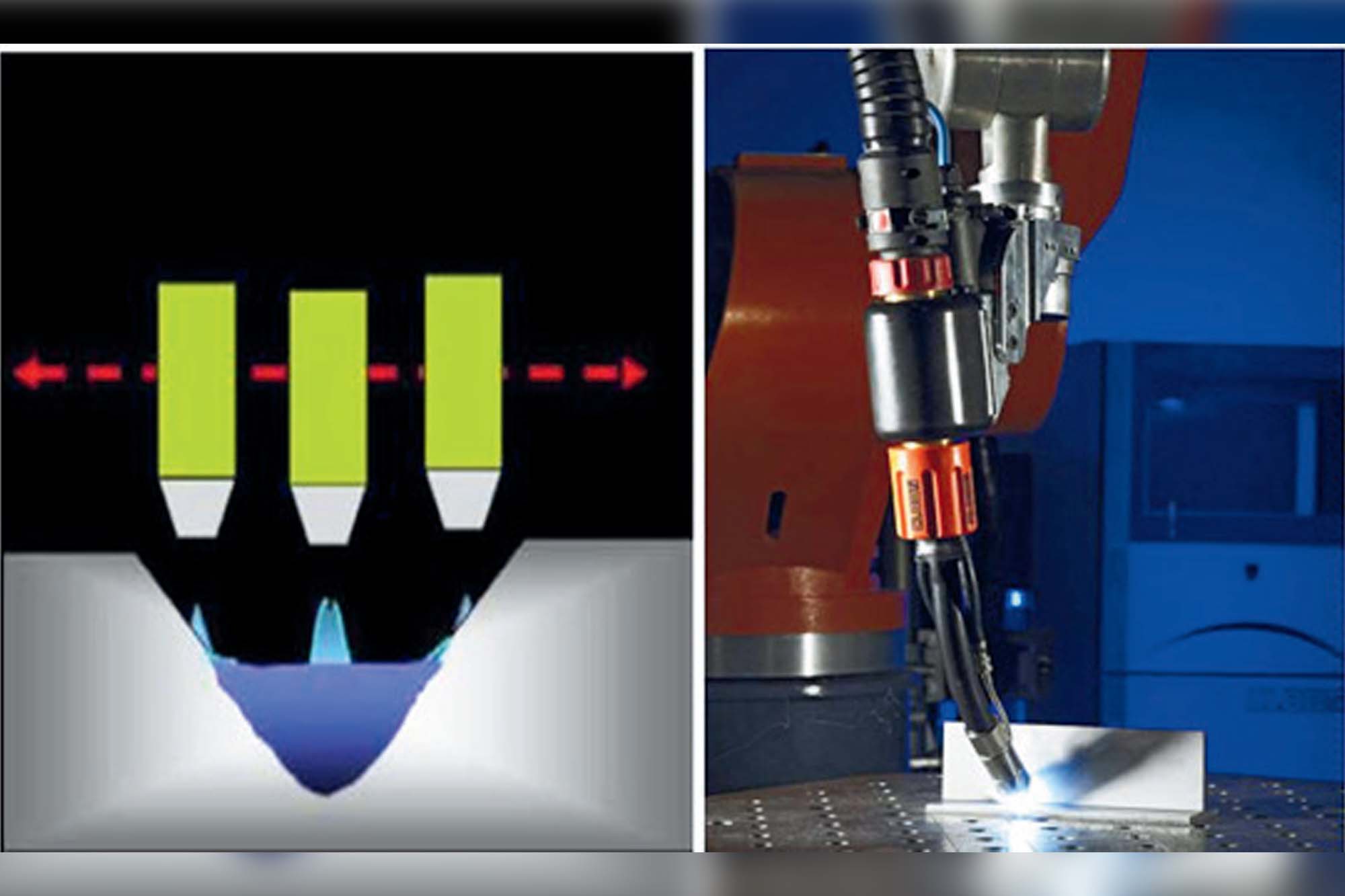

Tandem weld – Efficient welding times two

Tandem welding can be universally applied to both thin and thick plate welding. In the Tandem Weld process, two arcs burn in a common molten pool. The process is based on two electrically separated processes to match each other perfectly. This possibility opens up a multitude of combinations. The front wire ensures a safe penetration, and the back wire quickly fills big joints with filler material. The high deposition rate can result in weld speed and volume filling.

Tandem weld is suitable for thin and thick plates, allowing manufacturers to reduce welding times due to its high deposition rate. Manufacturers can reduce the component distortion and avoid extensive reworks due to the low heat input. Compensate material tolerances due to the gap-bridging ability. Tandem welding can be used for materials and thicknesses.

If manufacturers wish to maximise the efficiency of weld production? Then rely on Tandem Weld by CLOOS!

Digitalised production with CLOOS C-Gate

The digital revolution is in full swing, and welding is no exception. The digital revolution is in full swing, including welding. Monitoring and controlling production in real-time is crucial. With CLOOS C Gate, all digital solutions are in one place.

How CLOOS can help:

Digitalised production provides real-time monitoring and control on an integrated platform.

Interlinked robot welding solutions that increase productivity with precision and speed.

Sustainable technologies harmonise welding processes with environmental goals.

Human-robot collaboration encourages a versatile workforce and helps eliminate the shortage of skilled labour.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.