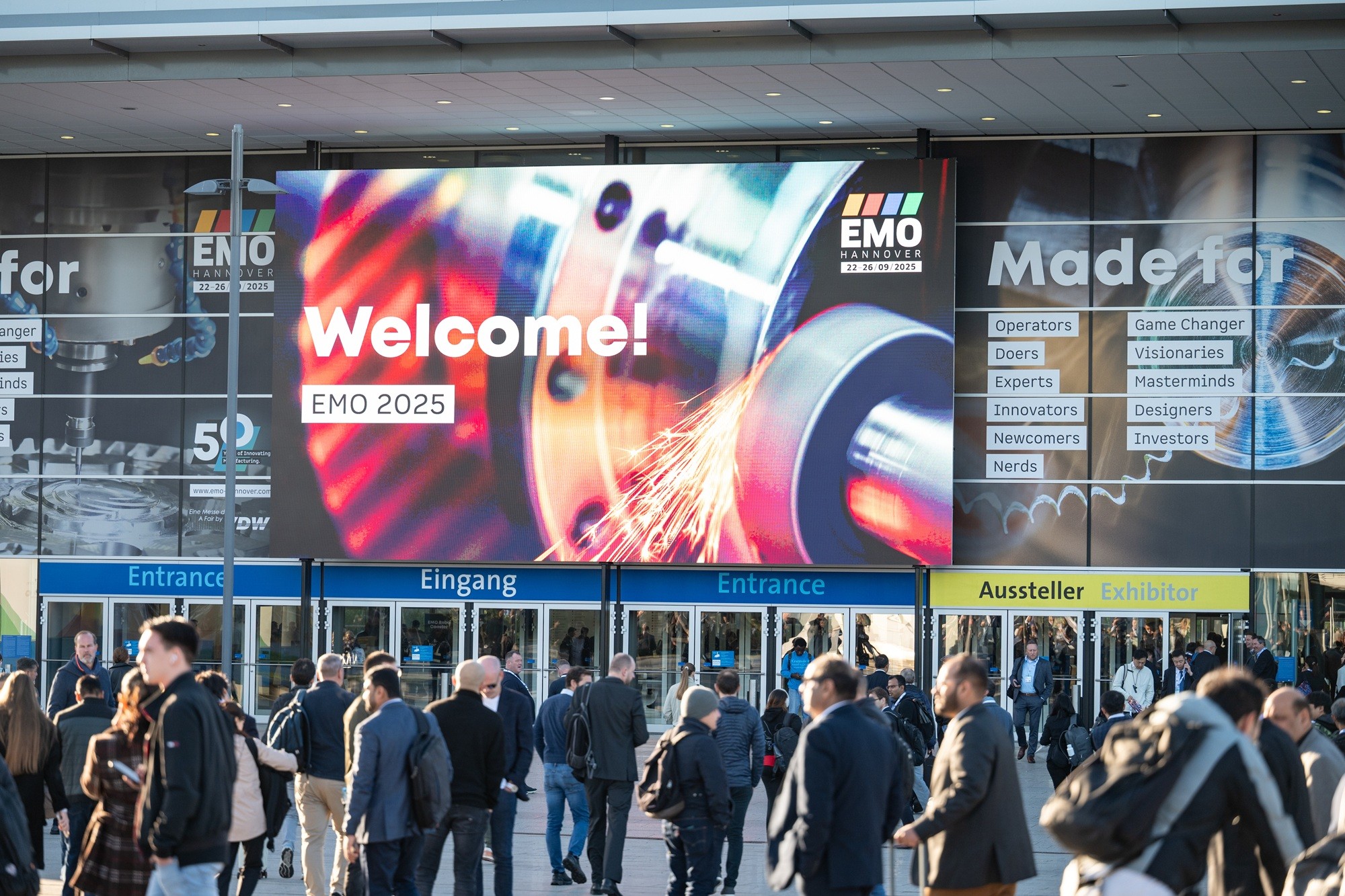

Sustainability leads the way at EMO Hannover 2025

By Staff Report June 25, 2025 12:42 pm IST

EMO Hannover 2025 highlights sustainable solutions from leading manufacturers, focusing on resource efficiency, emissions reduction, and circular production.

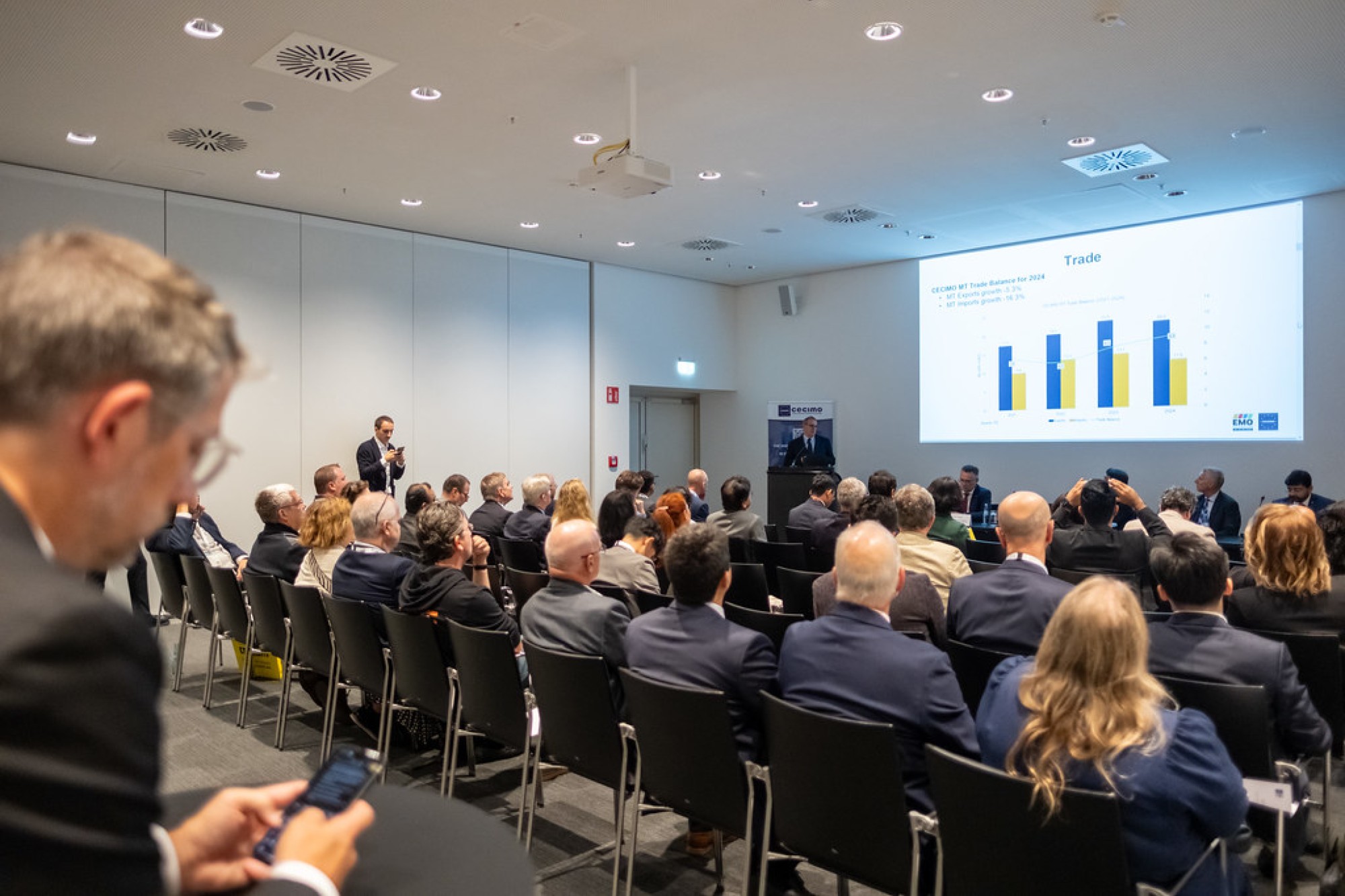

Sustainability will be a core theme at EMO Hannover 2025, with exhibitors demonstrating resource-efficient production methods, emissions reduction plans, and circular economy concepts. These programmes protect the environment and the climate, help firms remain competitive, and support their obligations to future generations.

Promoting Carbon Footprint Transparency

Ceratizit Deutschland GmbH is taking focused initiatives to reduce CO₂ emissions throughout its value chain. A significant component is a proprietary recycling technique that allows for the recovery of raw materials from secondary sources, lowering the product’s carbon footprint (PCF).

Dr Andreas Lackner, our chief executive officer, commented, “Our aim is to establish a common standard for calculating and classifying the carbon footprint of cutting tools, hard material solutions, and carbide powders. Ceratizit created a PCF model that contributed to VDMA standard sheet 35111, which is now used as an industry reference.”

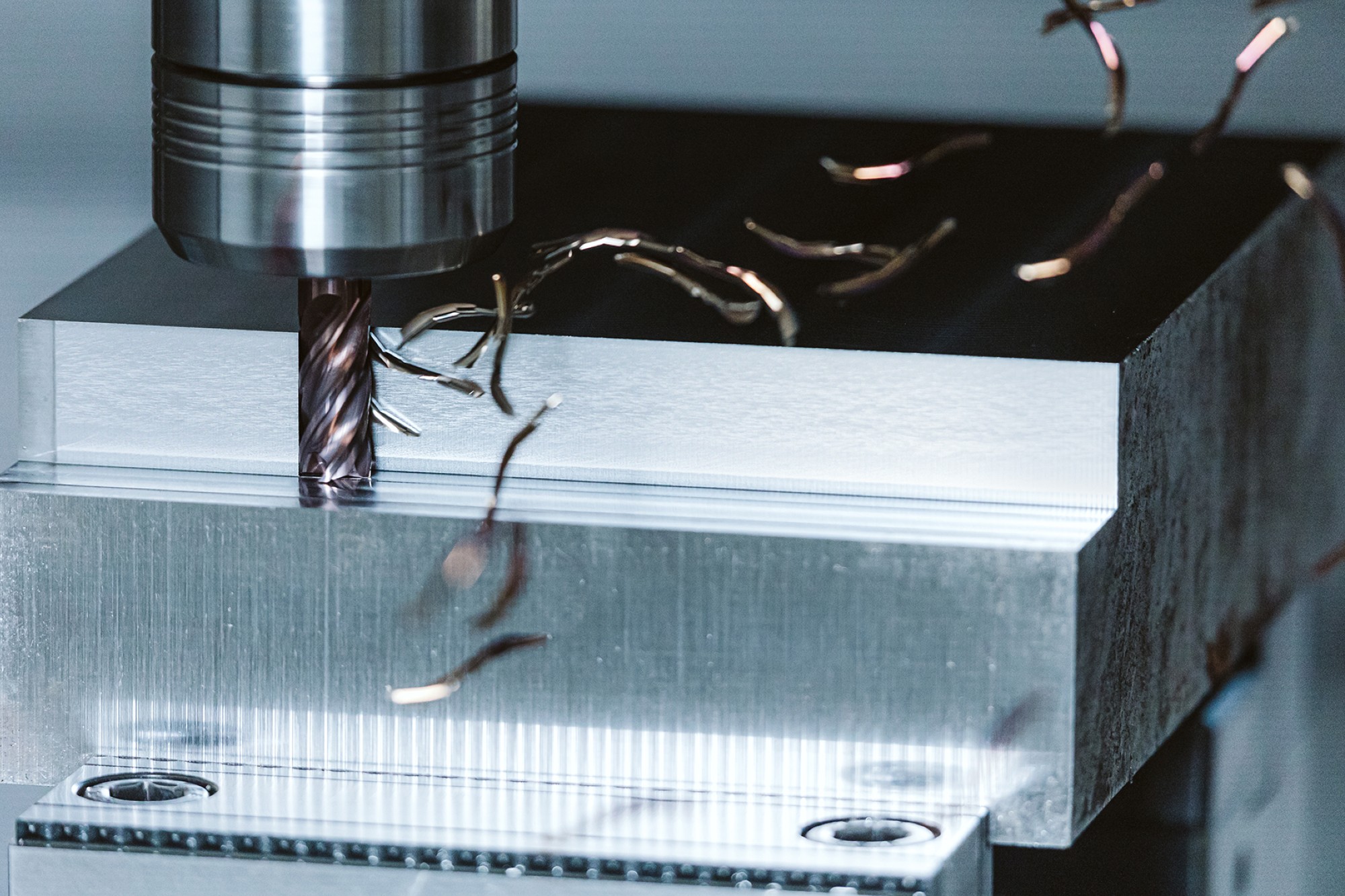

A milling cutter line constructed from 99% recovered carbide offers up to 30% greater performance and the lowest CO₂ emissions in its class.

Practical Sustainable Measures

Ingersoll Werkzeuge GmbH, situated in Haiger, has undertaken several sustainability efforts, including eco-friendly packaging, regrinding services to extend tool life, and a photovoltaic system generating 700,000 kWh yearly, saving around 184 tonnes of CO₂.

Leon Pulverich, Environmental and Energy Management Officer, stated, “We have taken various measures to reduce our ecological footprint while remaining economically efficient. When selecting new machines, the corporation prioritises energy efficiency in order to cut consumption and operating expenses.”

Developing Tools for a Greener Future

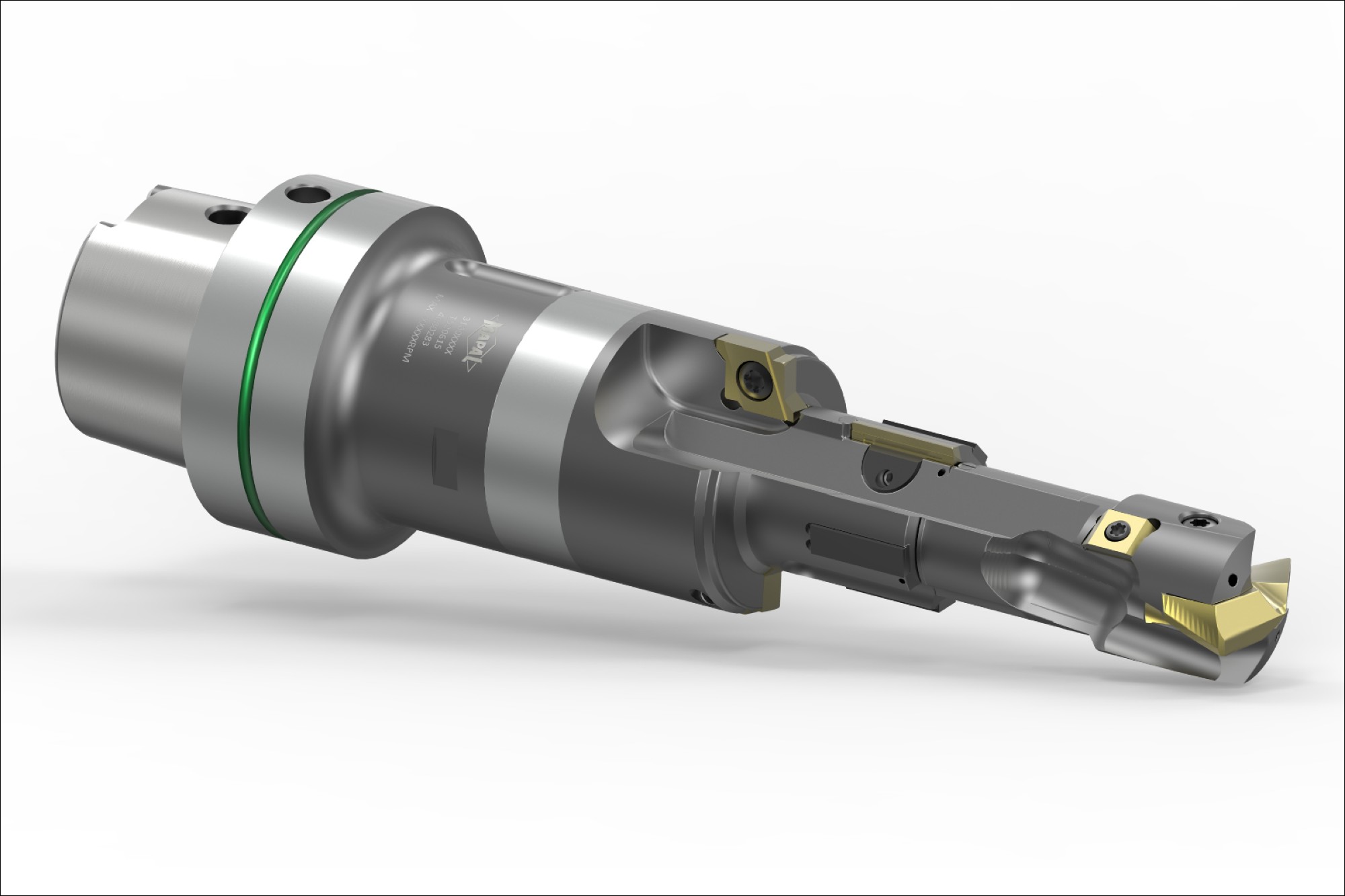

Mapal Dr. Kress SE & Co. KG specialises in sustainable tool design. Combination tools reduce tool changes and machine run times, resulting in energy savings. MQL-compatible tools reduce coolant usage and disposal expenses. Replacement head systems and reconditioned tools help to prevent material waste.

According to Jacek Kruczynski, chief technology officer, “Sustainability is not a foreign concept at Mapal but an absolute matter of course in our ideas and developments. The award-winning Uniq hydraulic chuck has a tenfold service life and uses less energy than standard alternatives.

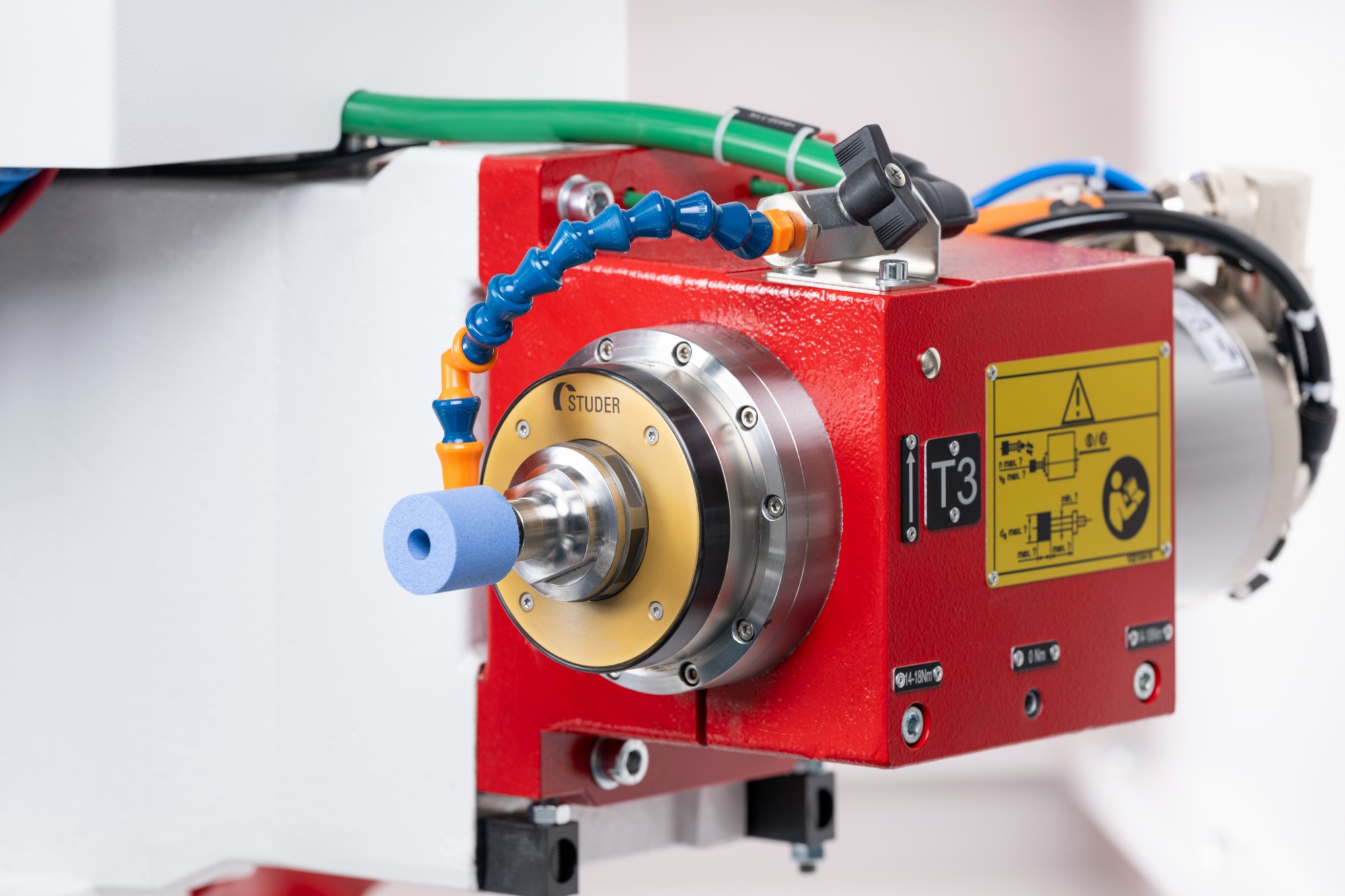

Optimising Machines for Efficiency

Kapp Niles GmbH & Co. KG has updated its grinding machines to improve energy and material efficiency. FEM-based component design, frequency-controlled pumps, and electronic systems have replaced traditional hydraulic systems, resulting in significantly lower energy use.

Additive manufacture of coolant nozzles increased efficiency by 60%, and mineral cast machine beds reduced CO₂ emissions. Intelligent shut-off functions and pressure-reduction technologies further cut power and air consumption.

Ralf Dremel, Head of Product Management, stated, “The EU Ecodesign Regulation presents new challenges and opportunities for innovation. We see our internal sustainability goals as a way to secure future competitive advantages.”

EMO Hannover 2025 highlights sustainability, automation, and digitalisation as major themes for the future of manufacturing. Visitors will see innovative solutions and interact with global industry leaders driving transformation.

For more information, visit www.emo-hannover.de.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.