How a homegrown lubricant brand is powering Indian industry

By Staff Report June 30, 2025 2:22 pm IST

Molygraph Lubricants is one of India’s leading manufacturers and suppliers of high-performance speciality lubricants and greases, catering to a wide range of industrial applications. To gain insights into the company’s journey and growth, we spoke with Arati Vora, Director of Research and Development, Quality Control, and Operations at Molygraph Lubricants. With 38 years of impressive experience in the speciality lubricants industry, she shares valuable perspectives on Molygraph’s inception, key milestones, and how the company has successfully built a distinct reputation within the industry.

Please tell us about Molygraph Lubricants’ journey from its inception and the idea behind its origin. What gaps did it aim to address in the Indian market?

Molygraph Lubricants began its journey over five decades ago with a simple yet powerful vision: to bridge the gap between global-quality speciality lubricants and the growing needs of Indian industries. At the time, India heavily relied on imported lubricants for critical applications, especially in the metalworking and MRO sectors. We recognised the opportunity to offer indigenously developed solutions that matched international standards in performance and reliability. With a strong focus on tribology and in-house R&D, Molygraph Lubricants set out to become a technology-driven partner for industries seeking customised, high-performance lubrication solutions. Today, our legacy is built on consistent innovation, technical expertise, and a customer-first mindset.

What are the company’s biggest challenges, and how are you addressing them?

One of the key challenges we face is raising awareness about the importance of using the right lubricant rather than just any lubricant. Lubrication is often overlooked in preventive maintenance strategies, leading to avoidable failures and downtime. Another challenge is adapting to the rapidly changing technological and sustainability expectations of industries. We address these through continued investments in training, customer education, and collaborative R&D. Our technical team works closely with clients to conduct site trials, failure analyses, and training workshops, ensuring that our solutions are well understood.

What sets Molygraph Lubricants apart from other lubricant manufacturers in terms of innovation and product development?

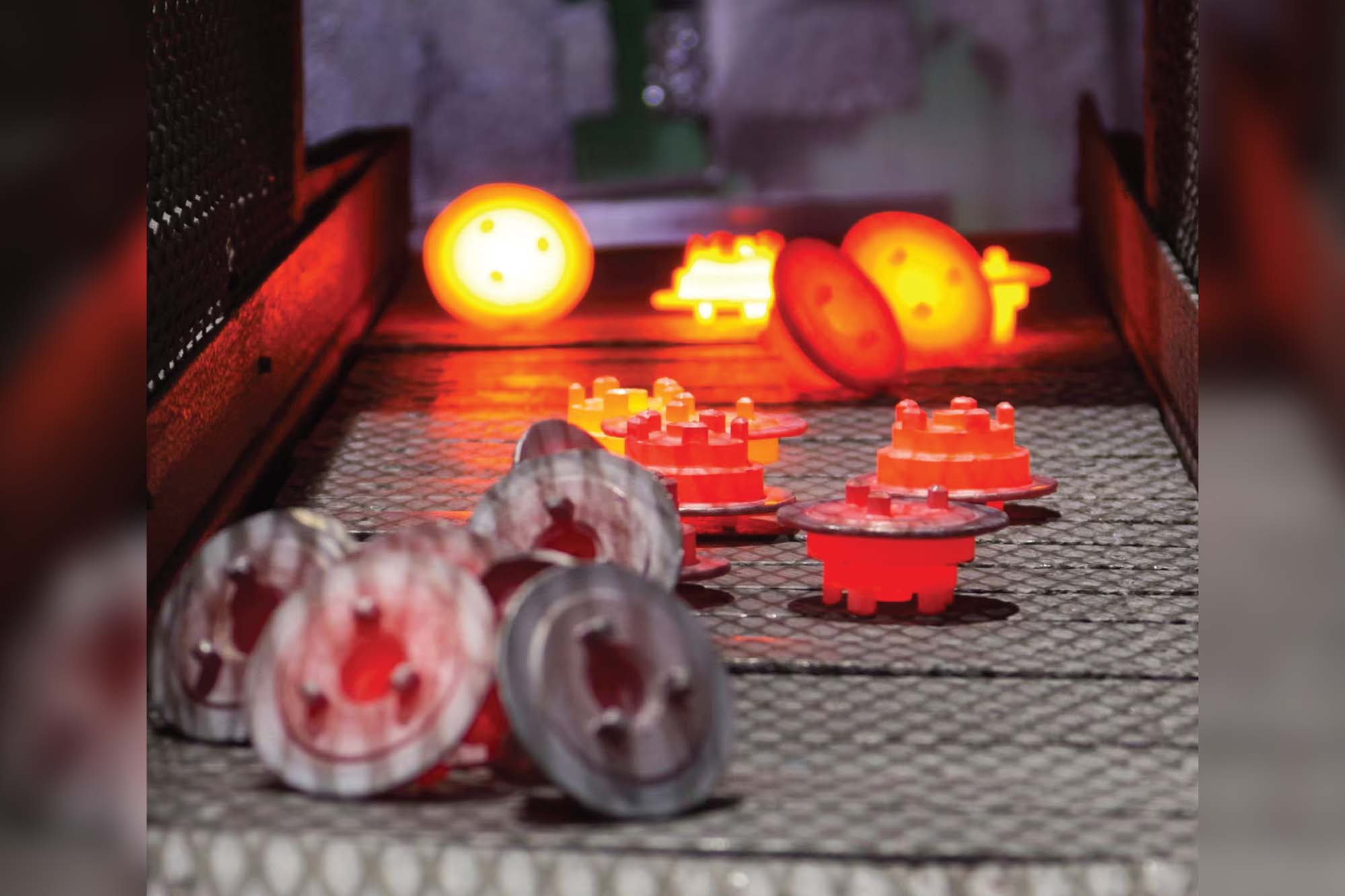

Our deep-rooted expertise in tribology sets us apart. We study the application and tailor our formulations according to the customer’s requirements. Our in-house R&D setup, with dedicated test rigs and an application simulation lab, allows us to innovate with precision. Our focus is on niche, high-performance applications such as food-grade lubricants, polyurea greases, hot forging lubricants, and aerospace metalworking fluids. Every product we develop is engineered to enhance efficiency, extend equipment lifespan, and minimise downtime.

How do you assess the unique lubrication needs of different industries, and what kind of consultative approach do you follow?

We follow a solution-centric approach rather than just selling a product. The process begins with understanding the operational demands and existing lubrication practices. Our technical experts conduct audits and performance mapping to identify areas for improvement. Based on this, we propose a lubricant that addresses wear, load, temperature, or contamination-related challenges. We closely monitor the performance through periodic reviews after deployment. This collaborative and consultative model has enabled us to establish long-term trust across various industries, including steel, food and pharmaceuticals, mining, cement, oil and gas, and others.

Could you share a recent example where your solution significantly improved a customer’s manufacturing or machinery performance?

One of our most notable recent success stories comes from the aerospace sector, where a leading manufacturer working with aerospace-grade materials was struggling with their existing coolant solution. The issues ranged from reduced tool life, frequent bacterial growth in the sump, and ineffective tramp oil rejection to poor pH and concentration stability, all of which impacted machining efficiency and overall costs.

We introduced them to our Smoothkut Pro 9100, a semi-synthetic coolant specifically engineered for high-performance and precision machining applications. The results were outstanding. The product extended the sump life and enhanced tool longevity while preventing rust and bacterial formation. It demonstrated excellent tramp oil rejection and maintained a stable emulsion even with hard water up to 500 PPM. Additionally, it delivered an improved surface finish, all at a competitive, pocket-friendly price. This solution addressed every performance parameter the client had and helped them improve efficiency without escalating costs.

How does Molygraph Lubricants leverage its expertise in tribology to develop tailored lubrication solutions for diverse industrial applications?

Tribology is the backbone of our R&D. Our experts constantly analyse wear patterns, lubrication film behaviour, and frictional losses across applications. We combine this with real-time data from the field to simulate conditions in our test rigs and develop formulations that address specific issues, such as metal-to-metal contact, corrosion, or thermal degradation. With close collaboration with OEMs and plant engineers, we ensure that each product enhances equipment reliability, extends its life, and meets sector-specific demands, from high-speed spindles to extreme pressure environments.

What future trends in industrial lubrication are you preparing for, and how is Molygraph Lubricants adapting to stay ahead of the curve?

The future of industrial lubrication is being increasingly shaped by sustainability, environmental responsibility, and the shift toward biodegradable and renewable solutions. We are actively working on expanding our portfolio to include biodegradable lubricants that are safer for both operators and the environment. As regulations tighten and industries move toward greener practices, the demand for low-toxicity, eco-friendly, and energy-efficient lubricants is on the rise, and we are preparing to meet that head-on.

We are also exploring how lubricants can support clean energy sectors, such as wind, hydro, and solar, in their manufacturing processes. Our commitment lies in reducing carbon footprints, enhancing waste management practices, and investing in R&D that focuses on renewable chemistry and principles of the circular economy. As a forward-looking company, Molygraph Lubricants aims to align with global sustainability goals while continuing to deliver high-performance solutions that empower industries to operate responsibly and efficiently.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.