Where are you on the automation curve?

By Staff Report August 1, 2025 6:40 pm IST

Automation has gradually become a part of our daily lives, from automatic bill payments to email auto-replies. Everyone at the household level now deploys the rudimentary automation. The concept becomes more complex as we discuss larger businesses that operate in extensive spaces where they manage multiple bills and salary deposits. These businesses must understand what works best for them. Companies should strive to develop adaptive systems that support their workforce while addressing challenges such as workforce shortages, legacy integration, and sustainability goals, all while being mindful of costs.

Companies are on a fervent search for automation solutions because they want to become more flexible and faster. There is a lingering question about which solutions will best suit us and reduce the documentation flow. How can the shortage of skilled employees be filled? But, firstly, we need to understand what automation brings with it and how the systems and data help the manufacturing processes in the long run.

Addressing the pain points

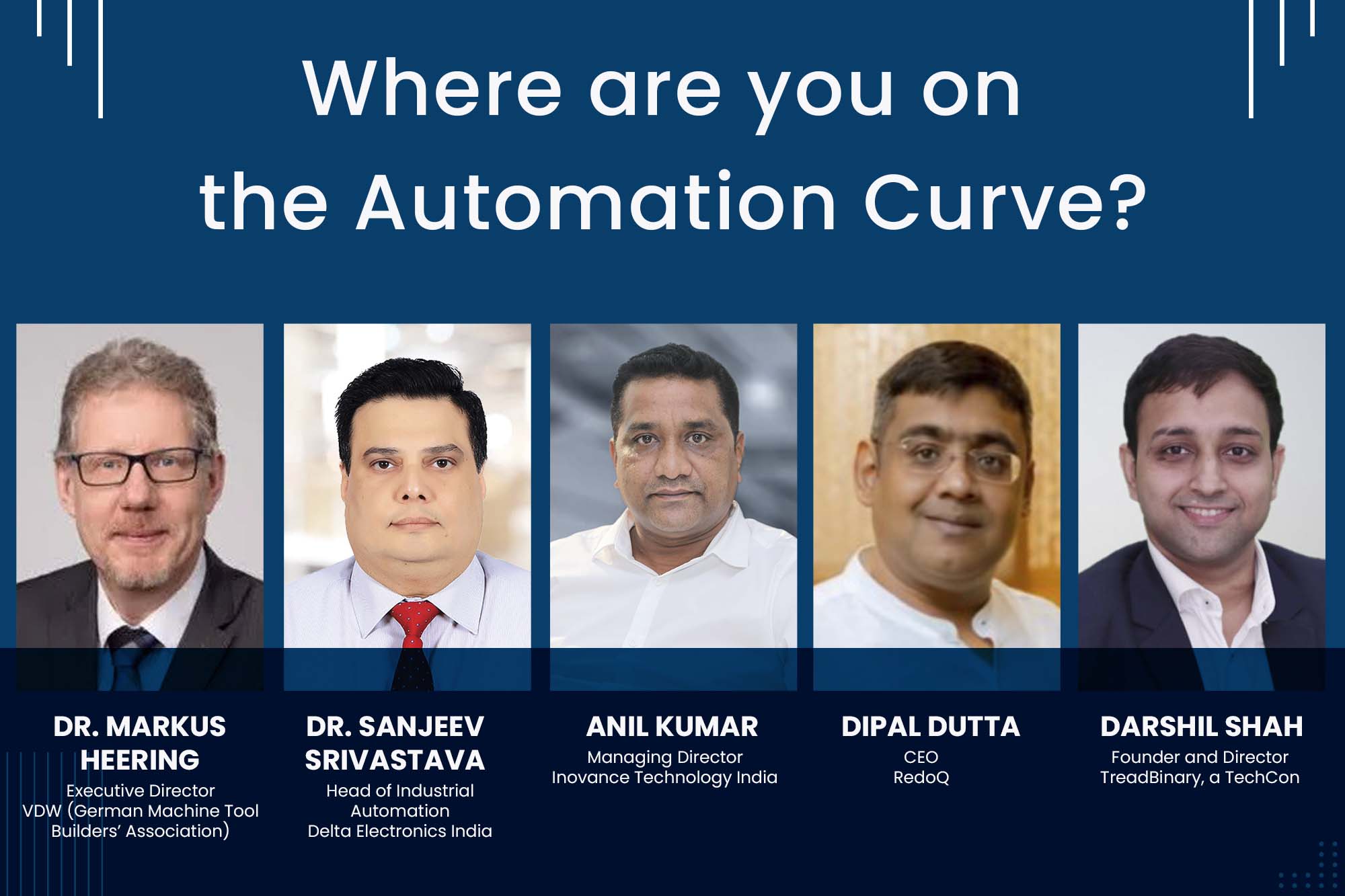

When we talk about adapting autonomy, several concerns need to be addressed first. While speaking to Dr. Sanjeev Srivastava, Head of Industrial Automation at Delta Electronics India, he explained that Indian manufacturers, especially small and medium-sized enterprises (SMEs), face challenges in adopting automation. These challenges include high upfront costs, a lack of skilled workers, old infrastructure, and limited knowledge about return on investment (ROI). Additionally, resistance to change and unclear decision-making processes hinder the implementation of new technologies.

The industrial sector often combines old systems with new technologies, making it difficult and expensive to introduce automation solutions. There is also a shortage of professionals skilled in both operations and information technology, which is crucial for properly maintaining and improving advanced systems. Furthermore, issues like data silos and a lack of system compatibility limit the effectiveness of automation.

Some organisations find it hard to show a clear ROI, particularly if they are reluctant to make large upfront investments. This challenge is related to the complexity of automation and the skills gap, leading to longer and resource-heavy initial deployments.

Indian manufacturing facilities vary greatly, from small workshops to large automated plants. However, issues such as changing temperatures, voltage fluctuations, dusty environments, and different skill levels among workers complicate automation. Companies can address these problems by using durable, temperature-resistant equipment, simple programming tools, and modular systems that allow for gradual automation.

Anil Kumar, Managing Director of Inovance Technology India, mentioned that when they encounter these challenges, they provide thorough training and support after deployment to ensure a smooth transition and minimal learning curve for users.

Automation as a multiplier, not replacer

At a recent preview of EMO Hannover 2025, held in Germany, Dr. Markus Heering, Executive Director of VDW (German Machine Tool Builders’ Association), emphasised that “Against the background of higher costs and a shortage of skilled workers, automation is vitally important for the industry.” To benefit from the desired competitive advantages, the user and solution must be a perfect match. Not every company has the same automation requirements, and solutions must be consistent to be truly effective. According to Heering, an important basic requirement is that the systems are easy to operate, scalable and flexible enough to adapt to individual requirements. In addition, it must be possible to integrate the solutions for both large series runs and the economical production of items.

Simple automation solutions include pallet changers and handling systems. A growing trend is the integration of ancillary processes such as cleaning, labelling or measuring, explains VDW. Many machine manufacturers are upgrading their machines with automation solutions and supporting operators with intuitive user interfaces and assistance systems. Even events like EMO Hannover* or Automation Expo**, India, are focused on bringing systems for industrialists that use AI (artificial intelligence) to provide employees with optimal support, whether by answering questions, providing instructions, or offering solutions to problems. This is expected to be particularly useful in future to support new or less experienced employees.

Asks of manufacturers

A growing number of manufacturers today are prioritising retrofitting solutions over system replacement to manage modernisation costs. Darshil Shah, Founder and Director, TreadBinary, a TechCon, shares that the focus should be to integrate IoT modules with existing equipment, allowing clients to extract actionable data from legacy assets without disrupting operations. This staged upgrade offers flexibility, allowing firms to continue using their current systems while planning phased transitions to embedded IoT-enabled units. As a result, firms can enhance their business outcomes without adding any additional burden. Taking an instance of an automotive manufacturer, they were able to achieve a 15 per cent reduction in energy consumption within a year by implementing IoT-based monitoring across legacy lines. With real-time visibility and predictive analytics built into interoperable systems, clients gain operational control without incurring the capital-intensive costs of overhauls. This approach is a smarter way to attain a smoother digital transformation journey.

Also, manufacturers now require predictive insights, real-time analytics, or plug-and-play interoperability – all three, but with a varying emphasis depending on their current stage of digital maturity. Real-time analytics is almost a baseline expectation. Manufacturers need immediate visibility into their operations to identify problems and track performance.

Building on that, manufacturers want to anticipate equipment failures, predict quality issues, and optimize production schedules using predictive analytics. For this, the manufacturers seek solutions that can connect to their existing infrastructure, diverse equipment, and IT systems with minimal effort. They want to avoid vendor lock-in and accelerate time-to-value.

Data security

Data security is important when dealing with sensitive operational data in smart manufacturing. Dipal Dutta, CEO of RedoQ, shares an interesting approach where their security systems are baked into the architecture of all their solutions from the ground up. This includes advanced encryption, secure authentication protocols, and rigorous access controls. He shares, “Businesses must follow industry best practices and compliance standards. They should conduct regular security audits and assessments to ensure their systems meet high standards. A hybrid model is often the best choice for smart manufacturing, as a “one-size-fits-all” solution rarely works well. Commonly used methods for secure data management include APIs, secure gateways, and data anonymisation techniques. These help maintain high data integrity.”

Many manufacturers are cautious about using cloud-driven models because they worry about data privacy. Using edge-based processing keeps sensitive tasks local while sending only summary insights to the cloud, and this method can prove helpful. This is a hybrid approach that leads to better performance while protecting the data.

Another aspect to consider is the teams that often work in isolation. They may not be aware of how quickly technology is changing. In such cases, manufacturers can use integrated automation solutions. Manufacturing Execution Systems (MES) and Industrial Internet of Things (IIoT) enable real-time data sharing, and this improves collaboration. Cloud-based Enterprise Resource Planning (ERP) systems and workflow automation tools make communication and decision-related work easier. Teams can work together when AI-driven analytics and digital twin technologies give valuable insights and simulation options. Collaborative robots (cobots) improve the way humans and machines work together, while knowledge management platforms keep teams informed.

Automation has become a necessity for manufacturers due to the fierce competitive nature of the market. The focus is now on creating solutions that are scalable, interoperable, and supportive of human operators. These solutions must also integrate with existing legacy systems while providing predictive insights and real-time analytics. Current trends such as edge computing, AI-driven decision-making, and hybrid cloud models are addressing concerns around data security and operational efficiency. As labour shortages and cost pressures continue, retrofitting and modular automation provide flexible pathways for digital transformation.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.