Safeguarding people and machines

By Staff Report August 22, 2025 12:47 pm IST

Operational efficiency and safety are crucial in industrial settings. The entire lifecycle of a machine, from its initial design to production and daily operation, must be developed with a strong focus on safety. A secure working environment protects employees and boosts their confidence, leading to improved productivity and efficiency. Pilz, an expert in safety solutions, has a comprehensive portfolio to address these issues.

Pilz, an industrial automation and safety technology provider, has automation solutions that prioritise safety. Their portfolio includes safety controllers, sensors, and motion control systems designed to protect machines and personnel. Pilz offers a comprehensive suite of services, including risk assessments, compliance consulting, safety design, validation, and training, all aligned with internationally recognised safety standards. Pilz helps manufacturers and end-users implement innovative safety technologies in compliance with international and regional safety regulations operating in over 40 countries, focusing on industries like robotics, intralogistics, packaging, railway, combustion, hydrogen, automotive, and many more. With Pilz, businesses can expect automation technology that integrates machinery safety and security.

Pilz’s approach to industrial security

Industrial security focuses on protecting production and industrial plants from intentional and unintentional threats, such as cyberattacks, system manipulations, and unauthorised access. Pilz believes that safety and security are interdependent and cannot be achieved without the other. With the rise of cyber threats, machine manufacturers and operators must implement smart security strategies. Evolving regulations, such as the EU Machinery Regulation, now incorporate cybersecurity measures for CE compliance. Industrial security aims to safeguard production facilities from cyberattacks and system vulnerabilities that could compromise machine functionality and worker safety.

Pilz addresses these challenges through specialised security solutions, including:

- SecurityBridge: An advanced application firewall that prevents unauthorised access to control networks, ensuring secure connections and data integrity.

- Identity and Access Management (IAM): Businesses can establish customised access controls, preventing unauthorised personnel from tampering with critical systems by using the PITreader and RFID transponder keys.

- Integrated Safety Solutions: Combining Safe Small Controllers (PNOZmulti 2) with the Safety Gate System, featuring safety switches like PSENmlock, PSENmgate, and PSENslock 2, provides a holistic safety and security framework.

- Diagnostic Solutions: Pilz has solutions to diagnose data to ensure that all safety components function efficiently, communicate properly, and allow manufacturers to detect and resolve potential risks before they escalate.

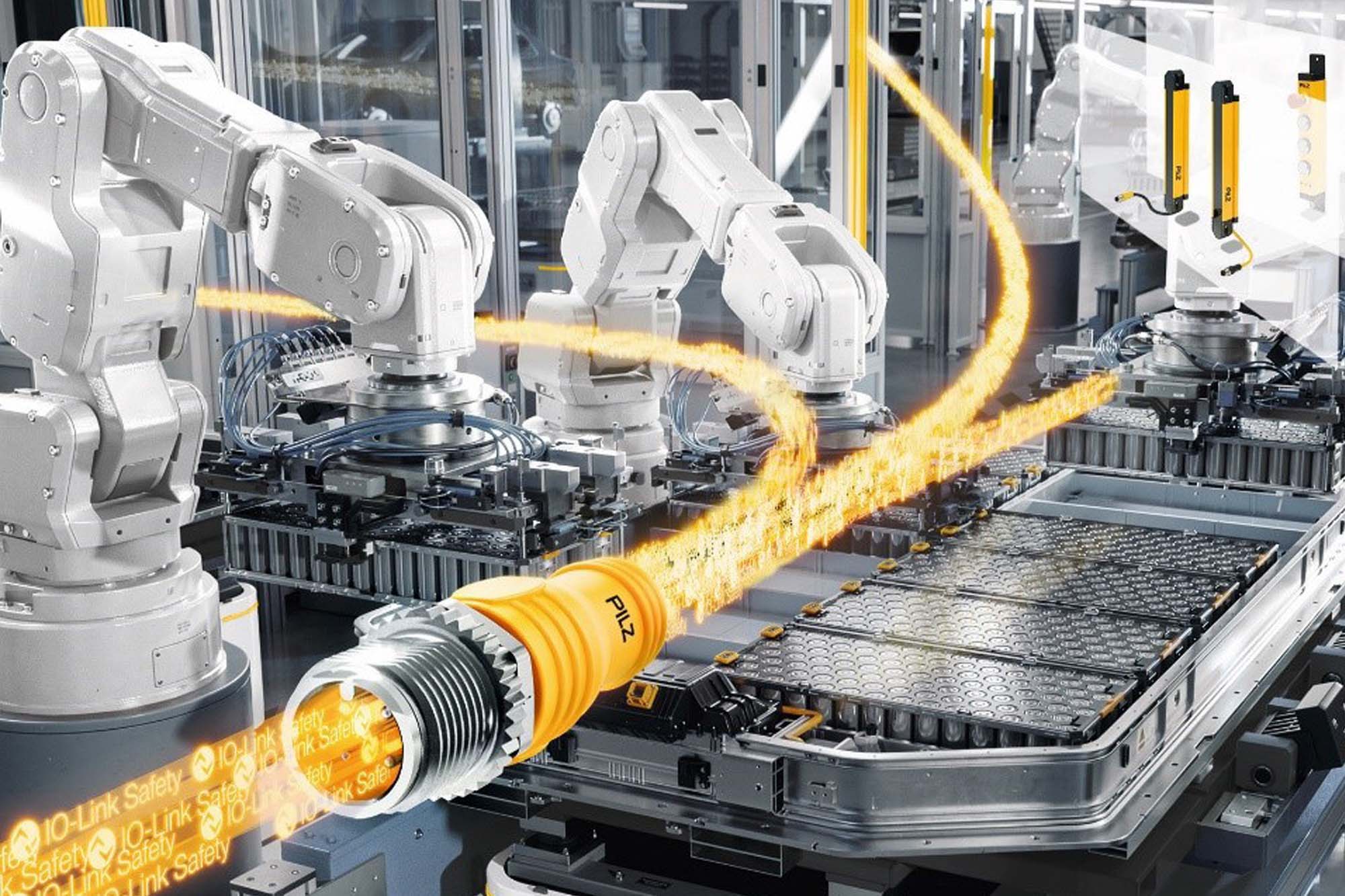

- Point-to-point communication: The IO-Link Safety of Pilz satisfies the wish for flexible automation. With the safe, standardised point-to-point communication IO-Link Safety, users can quickly and conveniently integrate sensors up to the field level.

In addition to these safe control and sensor technological solutions, Pilz provides structured training based on the IEC 62443 standard. The training modules cater to varying levels of expertise, helping businesses build a strong security culture and mitigate industrial threats. Pilz has expertise in industrial security and safety, through which manufacturers can meet evolving cybersecurity and safety regulations while maintaining operational continuity and employee protection.

Overcoming challenges through holistic safety services

Global economic trends and the demand for higher safety standards influence India’s manufacturing sector. While the sector significantly contributes to the economy, it faces challenges such as workplace hazards, industrial accidents, and complex compliance requirements. Addressing these challenges requires a collaborative approach to promote knowledge sharing, resource mobilisation, and the integration of innovative safety solutions.

Pilz offers a broad spectrum of safety services, and their approach to safety spans the entire machine lifecycle, from initial risk assessment to final commissioning. This systematic process includes:

- Risk assessment – Comprehensive evaluation of potential hazards associated with industrial machinery.

- Safety concept development – Tailoring safety solutions to mitigate identified risks.

- Implementation – Integrating the necessary safety components and systems into the machines.

- Validation & commissioning – Ensuring installed safety features function correctly and meet regulatory requirements before full operation.

Pilz adheres to key global standards – ISO 13849, IEC 62061, and the New Machinery Regulation. They also hold expertise in compliance related to regulatory frameworks such as NR12 (Brazilian regulation), UL compliance for the USA and CE marking for European Economic Area compliance. Pilz provides technical support in Design Risk Assessment (DRA), Site Acceptance Testing (SAT), and Factory Acceptance Testing (FAT) to ensure that safety measures are implemented and verified before a machine is deployed.

Pilz places a strong emphasis on workplace safety. Their consulting services assess and mitigate risks associated with human-machine interactions and hazardous environments. Pilz’s industrial security solutions, along with safety services and training, equip organisations to create a secure and efficient working environment. As a trusted partner, Pilz helps businesses navigate industrial safety and security complexities, ensuring regulatory compliance and a strong safety culture.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.