Dry cleaning without compressed air!

By admin August 21, 2015 6:13 pm IST

Intermediate cleaning of powertrain parts with over 50 per cent energy savings and high process reliability

Machined powertrain components undergo intermediate cleaning to safeguard the quality of subsequent process steps. This is typically done by means of compressed air, which must be generated at a high expense of energy. With their new EcoCVac, Dürr Ecoclean offers an effective dry cleaning system that eliminates the need for compressed air. Apart from delivering enhanced process reliability, the system can provide energy savings of more than 50 per cent. As maintenance of the working chamber is minimised, it also improves the machine availability.

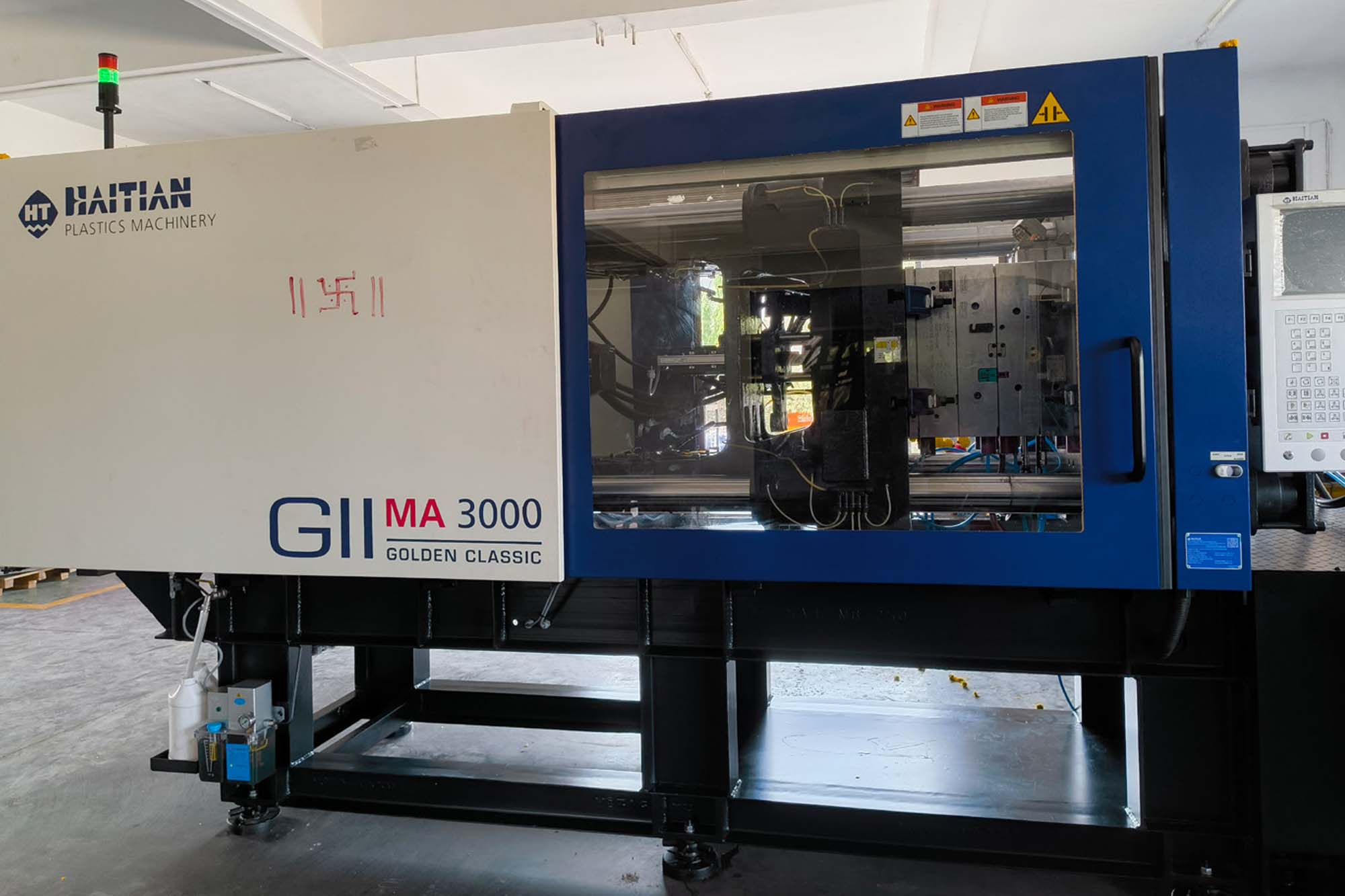

Modern engine and transmission manufacturing lines are designed for maximum productivity and economic efficiency. Accordingly, any cause of interference with a downstream process must be eliminated. This makes it mandatory that engine and transmission parts such as cylinder heads, engine blocks and transmission housings undergo cleaning operations between machining steps. Such intermediate cleaning is often performed by cleaning machines using compressed air. A benefit of this method is that the part is cleaned ‘dry’. On the downside, however, generating the compressed air supply is very costly. Moreover, the chips and machining fluid residues adhering to the product are merely blown off i.e. allowed to spread around in the work chamber, which will therefore become contaminated quickly. This, in turn, increases the risk of re-contamination of the product, with the possible result of impairing the next processing step.

Vacuum suction without compressed air in short cycles With its innovative EcoCVac pre-cleaning and intermediate cleaning system, Dürr Ecoclean of Monschau, Germany has overcome these drawbacks. The equipment relies on the newly developed vacuum suction technology. This ensures that contaminants will be removed not just from the part but also from the work chamber within a mere 1.5 to 3 seconds of process time.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.