Unlocking machine shop performance with Mobil™ Solutions

By Staff Report September 12, 2025 6:09 pm IST

Improper lubrication causes nearly half of machinery failures. This case study shows how Mobil™ solutions transformed a grinding operation, cutting costs, boosting efficiency, and improving sustainability.

Did you know that 43% of mechanical failures# in industrial machinery are due to improper lubrication? That’s not all—54% of bearing failures# also stem from poor lubrication practices. Imagine how much smoother operations could run by addressing this single issue! In fact, lubrication failures contribute to a staggering roughly 6% of the GDP in repair costs#, equating to over $1 trillion in losses#. In today’s fast-paced industrial world, where every second counts and precision is key, companies constantly seek ways to enhance productivity, extend machinery life, and cut operational costs. A critical factor, often overlooked, is lubrication—the unsung hero of industrial efficiency. With machines growing more advanced, the need for specialised lubricants that can withstand extreme conditions is greater than ever.

Mobil™ offerings for machine shops

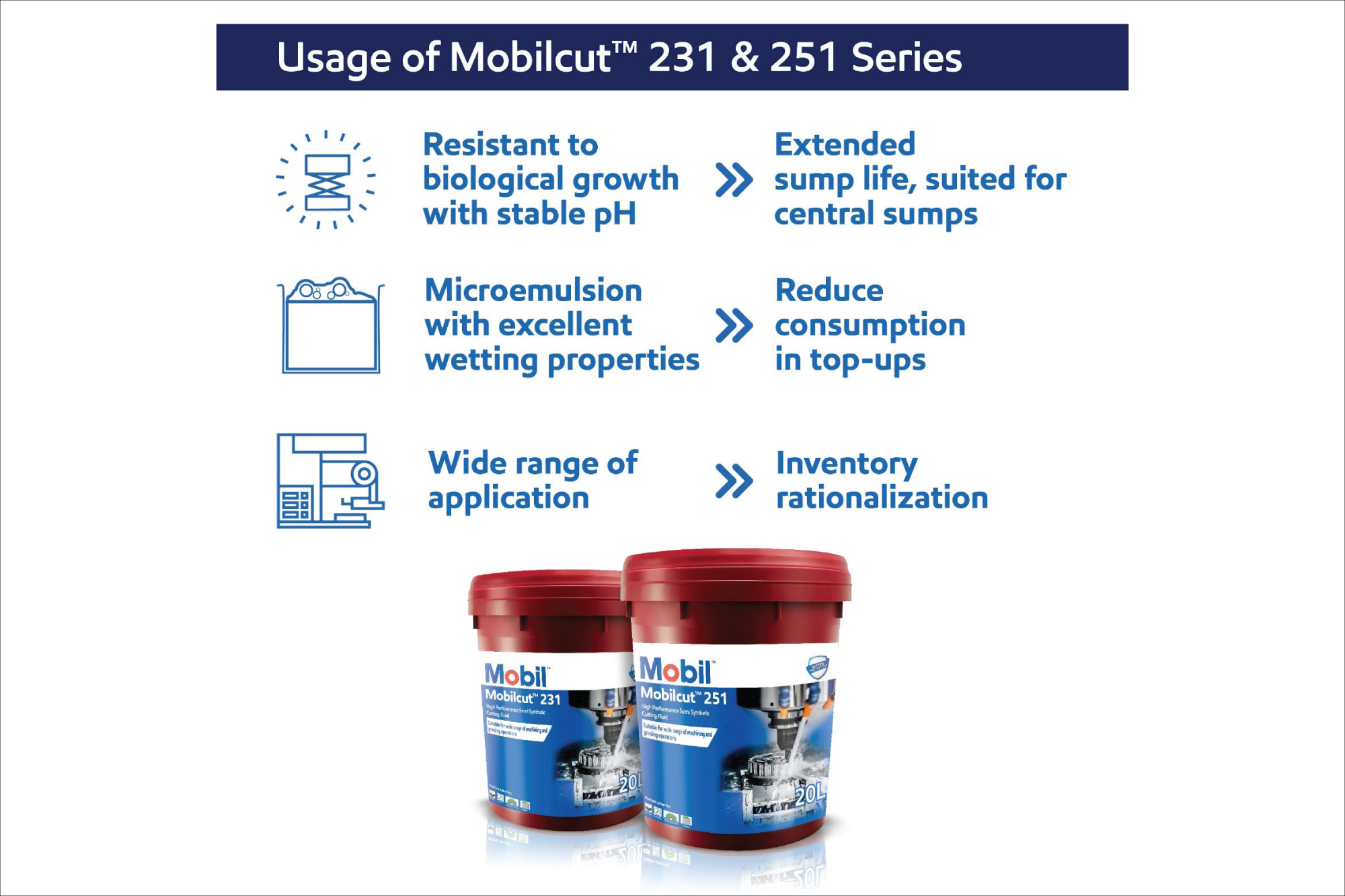

Mobil™ Industrial Lubricants offer slideway oils, hydraulic oils, spindle oils and cutting fluids, all designed to work together, helping reduce machine downtime and saving you the time and hassle of dealing with multiple suppliers.

In addition to high-performance metalworking fluids and lubricants, we provide a range of technical services to help keep machine shops running at peak efficiency while extending oil life, reducing downtime and lowering operating costs.

The Problem: A grinding operation facing high costs and operator concerns

At the heart of this story is a leading manufacturer operating multiple grinding machines for precision surface finishing. The shop was struggling with high cutting fluid top-ups, a short sump life of just 3–4 months, and operator discomfort caused by unpleasant odour when extending sump life with the existing cutting fluid. These inefficiencies led to increased expenditure, frequent disruptions, and a challenging work environment. The manufacturer needed a solution that could bring down costs, extend sump life, and improve operator comfort.

The Game-Changer: Mobilcut™ 251

Enter Mobil’s expert team, which recommended Mobilcut™ 251, a high-performance semi-synthetic water-soluble metalworking fluid. Formulated with microemulsion technology and enhanced wetting characteristics, Mobilcut™ 251 was designed to reduce excessive top-ups, extend sump life, and deliver a more operator-friendly experience. With the added support of Mobil™ Solcare services to monitor coolant health, the manufacturer was equipped with a comprehensive solution tailored to its grinding operations.

The Transformation: Results that speak for themselves

The introduction of Mobilcut™ 251 brought a remarkable turnaround. Here’s how the shop benefited*:

- Annual savings: Lubricant expenditure dropped by 64%, equating to savings of INR 509,880 annually.

- Extended sump life: The sump life doubled, improving machine availability and reducing downtime.

- Reduced top-ups: Cutting fluid top-ups reduced by 75%, ensuring more efficient operations.

- Operator comfort: Odour issues were eliminated, significantly improving the shop floor environment.

- Sustainability boost: The shop achieved an environmental improvement of 1,720 litres in reduced fluid disposal.

Beyond the direct cost savings, the manufacturer also experienced enhanced productivity, a safer workplace, and improved sustainability performance. The case highlights how the right lubricant can simultaneously address operational efficiency, cost, and employee well-being.

Why this matters: The bigger picture

This case highlights the critical role of lubrication in optimising machine performance, improving safety, and driving cost efficiency. For businesses in the manufacturing sector, the right lubricant is not just a technical choice; it’s a strategic decision that can give a competitive edge.

Mobil’s Advanced Services: Mobil™ Solcare and MachineXT

In addition to providing high-performance lubricants like Mobilcut™ 251, Mobil™ offers advanced services such as Mobil™ Solcare and MachineXT to optimise machinery health. Mobil™ Solcare monitors coolant performance, ensuring optimal fluid life and reducing waste, while MachineXT offers cutting-edge tools to enhance machine reliability and minimise downtime. Together, these services help manufacturers maintain equipment efficiency, lower operational costs, and improve sustainability, aligning with industry demands for precision and performance.

Mobil’s commitment to excellence

By offering tailored, high-performance solutions like Mobilcut™ 251, Mobil™ showcases its commitment to helping clients solve operational challenges, enhance sustainability, and achieve long-term success. This manufacturer’s success story is just one example of how the right lubrication practice can make all the difference.

In an industry where every detail counts, the impact of proper lubrication is clear: it’s not just about keeping machines running—it’s about powering businesses forward.

—————————————————————————————–

*This Proof of Performance is based on the experience of a single customer. Actual results can vary depending upon the type of equipment used and its maintenance, operating conditions, environment, and any prior lubricant used. Visit mobil.com/ industrial to learn how certain Mobil-branded lubricants may provide benefits for your equipment.

#Reference – Overcoming the Most Common Lubrication Misconceptions by Machinery Lubrication (Report by Machinery Lubrication)

(Exxon Mobil Corporation has numerous affiliates, many with names that include ExxonMobil, Exxon, Esso, and Mobil. For convenience and simplicity, those terms, and references to “corporation,” “company,” “ExxonMobil,” “EM,” and other similar terms are used for convenience and may refer to one or more specific affiliates or affiliate groups.)

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.