MOTOTECH 2025 ignites Pune driving India’s automotive transformation

By Staff Report October 9, 2025 5:28 pm IST

MOTOTECH 2025 returns to Pune, catalysing innovation, sustainability and growth across India’s automotive manufacturing ecosystem.

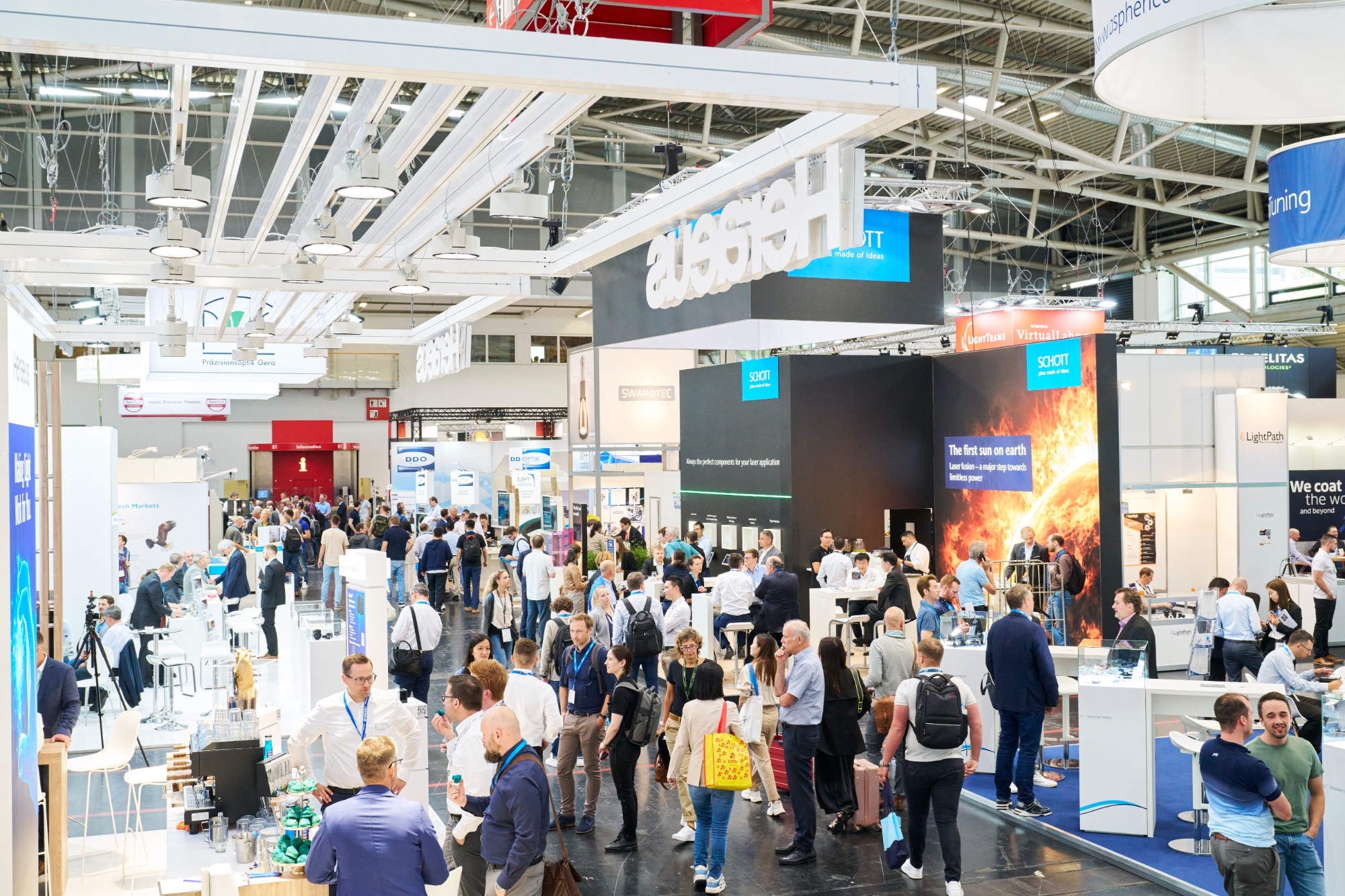

Pune, India — October 9, 2025: MOTOTECH 2025, India’s premier automotive expo and conference, returned to Pune on 9–10 October, driving innovation, sustainability, and growth through live technology showcases, expert dialogues, and transformative industry collaborations. The two-day platform convened OEMs, component makers, automation leaders, policy thinkers, researchers, and supply-chain strategists to accelerate India’s journey toward a globally competitive, future-ready automotive industry.

The conference opened with a keynote by Sachin Goel, Vice President and Head of Central Quality, Ashok Leyland, on “Quality in the Automotive Manufacturing Landscape.” Through the day, curated sessions spotlighted new approaches to sustainable manufacturing, digital product development, and shop-floor automation—underscoring how data, design, and disciplined execution are converging to redefine competitiveness.

Setting the strategic context, Conference Advisor Shailendra Goswami (CMD, Pushkaraj Group) said:

“Pune is a true automotive hub, and India itself is rapidly emerging as a global manufacturing hub. Before 2020, our focus was largely on domestic demand and conventional manufacturing practices. The post-COVID supply-chain rebalancing—where many buyers sought ‘China+1’ options—created a strategic opening. With India’s intellectual capital and our status as the world’s largest manpower supplier, if we channel this capability into manufacturing at scale, we can credibly become a global platform.”

He added: “Industry has moved from traditional methods to Industry 4.0 and now 5.0—where cyber-physical systems are complemented by the human element: intuition, innovation, and real-time decision-making. AI-enabled smart manufacturing is no longer a theory; India is absorbing it at speed. While raw material and import dependencies remain, on capability and price competitiveness, we can meet global requirements, and Indian firms are already running sustainable global businesses.”

Goswami also emphasised the policy imperative: “Government intent is clear—raise manufacturing’s share of GDP to 25%. That means building a full ecosystem of Tier-1, Tier-2, Tier-3 and MSME suppliers. Automotive is central to this vision, and Pune’s cluster—from two- and three-wheelers to commercial vehicles, passenger cars and tractors—makes it the right place to convene technology, academia and industry. That’s why a conference like MOTOTECH is both timely and necessary.”

Delivering a keynote on competitiveness through logistics and operations, Dr Rakesh Singh (Chairman, Institute of Supply Chain Management) noted: “India is becoming a major production base that can serve global demand, even as China continues to supply many critical inputs. The domestic market is expanding fast—including in rural India, where SUVs on district roads are now commonplace. Exports are rising too.”

He continued: “This growth requires resilient, end-to-end supply chains. Supply chain isn’t just moving goods from A to B. It’s an integrated flow—from sourcing and inbound transport to manufacturing, distribution, dealers and customers—managed for cost, speed, reliability and profitability. Technology is central: IoT, AI/ML, AR, planning and forecasting tools, and digital twins to surface gaps virtually and fix them physically. Think of the supply chain like a river—it must flow without bottlenecks. If India wants world-class manufacturing competitiveness, our sourcing and selling supply chains must be seamless, data-visible, and among the best globally.”

Bringing the lens of electrification and entrepreneurship, Uday Narang, CMD, Omega Seiki Mobility, said:

“Pune and Maharashtra are forward-thinking—both in automotive and technology manufacturing. India has a unique opportunity right now. Learn from global leaders, but follow our own path. Our edge is a young, ambitious population—especially with the rising participation of women. We must convert that talent into builders and founders, not just job-seekers.”

“‘Country first’ must move from slogan to practice. Build alliances with Japan, Korea, Europe and the U.S., but build products here—not just import-and-assemble. In mobility, adoption will be driven by the total cost of ownership (TCO). If EV TCO undercuts ICE, consumers will switch—period. That pushes all of us to deliver quality, reliability and service. With founder energy, serious manufacturing, resilient supply chains and sensible global partnerships, India can lead. Put the country first—and make it happen.”

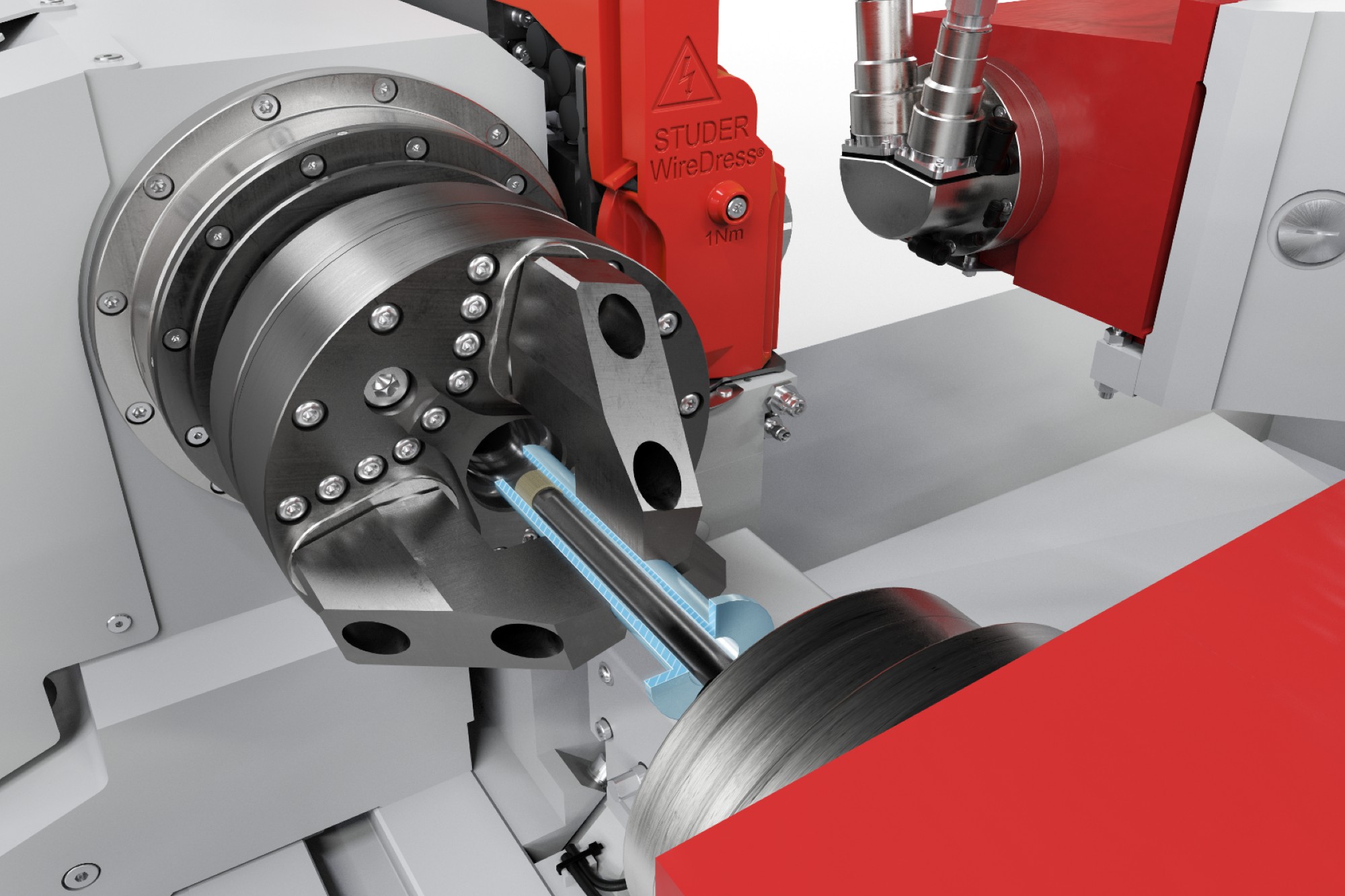

On the show floor, visitors experienced cutting-edge demonstrations and solutions from Universal Robots, ATI Motors, Triam Toolroom, Yash Dynamics, Schneider Electric, WAGO India, Jendamark, Dalmec, Shree Rapid Technologies, TASI India, Light Mechanics, Marposs, and others—spanning collaborative robotics, autonomous material movement, precision tooling, test and measurement, digital assembly, and advanced quality control.

Day Two will sharpen the focus on EV Leadership, Women in Manufacturing, Shop-Floor Excellence, and Future Skills—translating vision into practical playbooks for productivity, safety, sustainability, and workforce readiness.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.