Boost in productivity thanks to automation

By admin August 12, 2016 4:12 pm IST

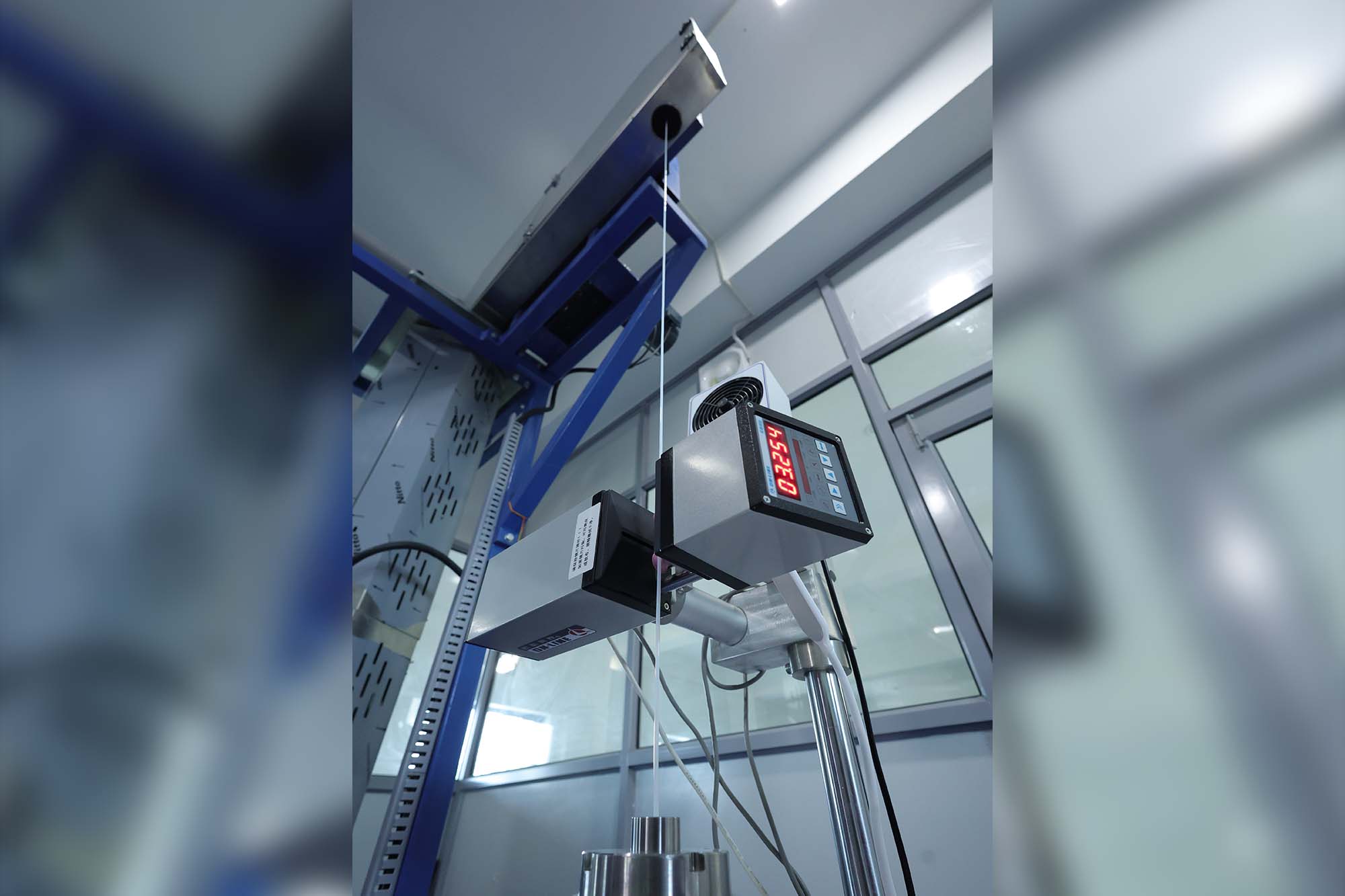

Since 2010, SPECK has consistently relied on automated machine tools from DMG MORI Systems in order to boost capacity in its production

SPECK PUMPEN Walter Speck GmbH & Co. KG from Roth produces more than 250,000 pumps and pumping systems for industrial applications a year. The company has been supplying customers in over 40 countries for more than 100 years. SPECK produces its specialised products primarily for customers from the medical technology, chemicals and pharmaceutical industries, for cooling and temperature control equipment and for the plastics industry. The high level of specialist expertise of its more than 450 employees worldwide is supported in mechanical production by state-of-the-art machine tools. Automated systems from DMG MORI have played a significant role here since 2010, as the latest investment proves. For this DMG MORI Systems linked a MILLTAP 700 and a CTV 160 using an automation solution.

When asked about the core competences and the differentiation features of his company, the CEO Wolfgang Krüger mentioned especially its innovative and application-orientated capability. “We unite this with a high level of flexibility in production and assembly in the manufacturing of our many different components and with short delivery times.” To appreciate the importance of this statement it is worth taking a look at the product programme. The company’s website mentions no less than 26 or rather 33 areas of application in its fluid and vacuum pump divisions. Its list of references includes standard applications in machine tool manufacture, in laser and welding technology or in agricultural and rail vehicle manufacture as well as the proverbial exotic use of special pumps for tobacco moistening. To accommodate this multitude of applications SPECK in Roth offers a total of 18,000 different pump versions in over 80 series – and often in different performance classes as well. So it is no surprise that there are no standard parts in the production halls. “The average batch size in mechanical production is just 50 to 100 parts.”

In view of the outlined requirements profile, the question as to the importance of its own production is easy to answer. Wolfgang Krüger points out the close interaction between machine tool, tool and cutting material and stresses: “The autonomous development of new or alternative manufacturing strategies and continuous further development in all the sectors mentioned are what boost the productivity of our manufacturing processes.” The company would lose a big portion of relevant expertise if it purchased workpieces from outside. “Added to this is the extremely high demand placed on the quality of the pumps.” In order to maintain a high degree of efficiency, the gap dimensions of the SPECK pumps are often in the range of a few hundredths of a millimetre. Such quality pressure is further intensified by the trend towards ever smaller pumps with an ever higher degree of efficiency.

DMG MORI Systems – minimum throughput times thanks to automationsThis productive form of manufacturing has grown dramatically in importance since 2010 when DMG MORI Systems installed the first automated machine tool – a CTV 160. A highly complex system comprising a CTX alpha 500 with stations for measuring, truing and pressing followed in 2011. A shaft and a rotor are connected to an armature shaft that SPECK produces for pump motors on this system within about a minute. “The original procedure involving several machining steps and a manual pressing process took far, far longer”, recalls Dieter Meier, Head of Mechanical Production. Nowadays all that is needed is to feed the automation solution with the orders for the different component variants and load the respective blanks. “The high level of precision achieved in machining is also of great benefit. Automated production scores points in this respect due to its high repeat accuracy.” Such automation drastically reduces throughput times and boosts quality while at the same time gaining time for the specialist workers to perform other tasks, as Dieter Meier goes on to tell us: “Our workers can operate several machines simultaneously during the autonomous machining cycles.”

It was this same motivation that lay behind the investment in meanwhile two such linked systems for the manufacture of motor bearing shields. Turning is carried out by a CTV 160 in both systems, while a MILLTAP 700 handles boring in the case of the newest automation. As DMG MORI did not have the compact machining centre in its programme in 2012, the older investment uses a DMC 635 V for this purpose. “The output of the two systems is enormous”, says Dieter Meier. SPECK produces over 250,000 motor bearing shields a year on the two respective linked machine tool systems.However, the high quantity does not mean that the actual batch sizes do not remain relatively small, as the Head of Production goes on to explain: “We need the components in a number of different diameters and variations, so both systems had to be set up to be extremely flexible.” DMG MORI Systems achieved such diversity in components by incorporating flexible chuck jaws. The equipment in the rotary magazine can be adjusted to the right diameter in no time at all.

DMG MORI Systems designed and implemented the two linked systems on the basis of the components. “We were able to start production within three months”, says Dieter Meier looking back at the fast realisation of the first system. Installation of the second system was even less complicated: “Apart from the MILLTAP 700 this system was identical in design to the first one, because we were more than satisfied with that first investment.”

Dieter Meier believes that automation is the future of manufacturing. He says, “With their short throughput times, higher capacity and considerable boost to productivity, due not least to multiple machine operation, automated manufacturing systems pay for themselves extremely quickly. Such machining solutions also simplify the work of our employees enormously.”

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.