IIoT devices help drive the next industrial revolution

By OEM Update Editorial June 12, 2018 6:21 pm IST

Varun Arora,

National Sales Manager, Exor India

Smart Manufacturing is the use of IoT devices to improve the efficiency and productivity of manufacturing operations. Typically, this involves fitting sensors to existing machines that will gather real-time data and analytics to make better and more informed decisions.

The role of IIoT in the future of manufacturing

The Industrial Internet of Things (IIoT) is changing business models, increasing outputs and automating processes across a number of industries. One sector that the Internet of Things (IoT) technology revolution has greatly impacted is the manufacturing industry.

Varun Arora, National Sales Manager, Exor India Pvt Ltd, informs, “Manufacturers across all areas have invested heavily in IIoT devices and they are already seeing benefits at this early stage of the IIoT. Most companies realise that making processes more efficient needs to play a key role in business strategy and by harnessing IIoT sensors and analytics, processes can be automated which will ultimately increase productivity.”

Manufacturers are converging a new breed of standard network architecture with “smart manufacturing systems” to connect formerly distinct production and business domains. The result is referred to as “Industry 4.0” in which Internet-based manufacturing networks are uniting the factory floor with enterprise-based systems and decision makers. There are many benefits of implementing IoT devices in factories.

Arora opines, “Smart manufacturing is the use of IoT devices to improve the efficiency and productivity of manufacturing operations. Typically, this involves fitting sensors to existing machines that will gather real-time data and analytics to make better and more informed decisions.”

Manufacturing is an essential part of business and transcends into other marketplaces such as retail and healthcare etc. In this new digital age, the consumer is looking directly to the manufacturer for new technologies to enable management of the supply chain and to ensure the supply chain is efficient and cost effective.

By 2020, it is estimated that 50 billion connected devices will be in use worldwide, meaning that manufacturers will have to keep pace with the ‘on demand’ consumer. This focus for change must adopt new business models and technologies such as the IoT and Industry 4.0 to facilitate convergence of the physical with digital manufacturing, enabling businesses to increase traceability, accountability and quality assurance.Industries that will drive IIoT adoption in 2018

According to a research by Business Insider, global manufacturers will invest $70 billion in IoT solutions in 2020. That’s up from $29 billion from 2015. This gives an idea on how much industries are focussing on implementing this new technology. Arora believes major industries that will drive the adoption in 2018 are manufacturing, transportation, utilities (power and gas distribution), healthcare and consumer electronics.

Exor’s preparedness in the area of IIoT

Arora informs, “The dramatic increase in the consumer IoT created great demand for enabled devices, services and solutions. Yet in the non-consumer world of industry, marine, etc there remains many challenges for companies, end users and the system developers.”

For many years the promised benefits of the IIoT were aspirations on the part of engineers, the technology simply was not sufficiently advanced. Now that has changed. The technology has indeed caught up with these aspirations and now concrete business cases are possible.

With unlimited go to market potential companies are looking for the best tools and technologies to enable them to create solutions that encompass the possibilities of the fourth industrial revolution.

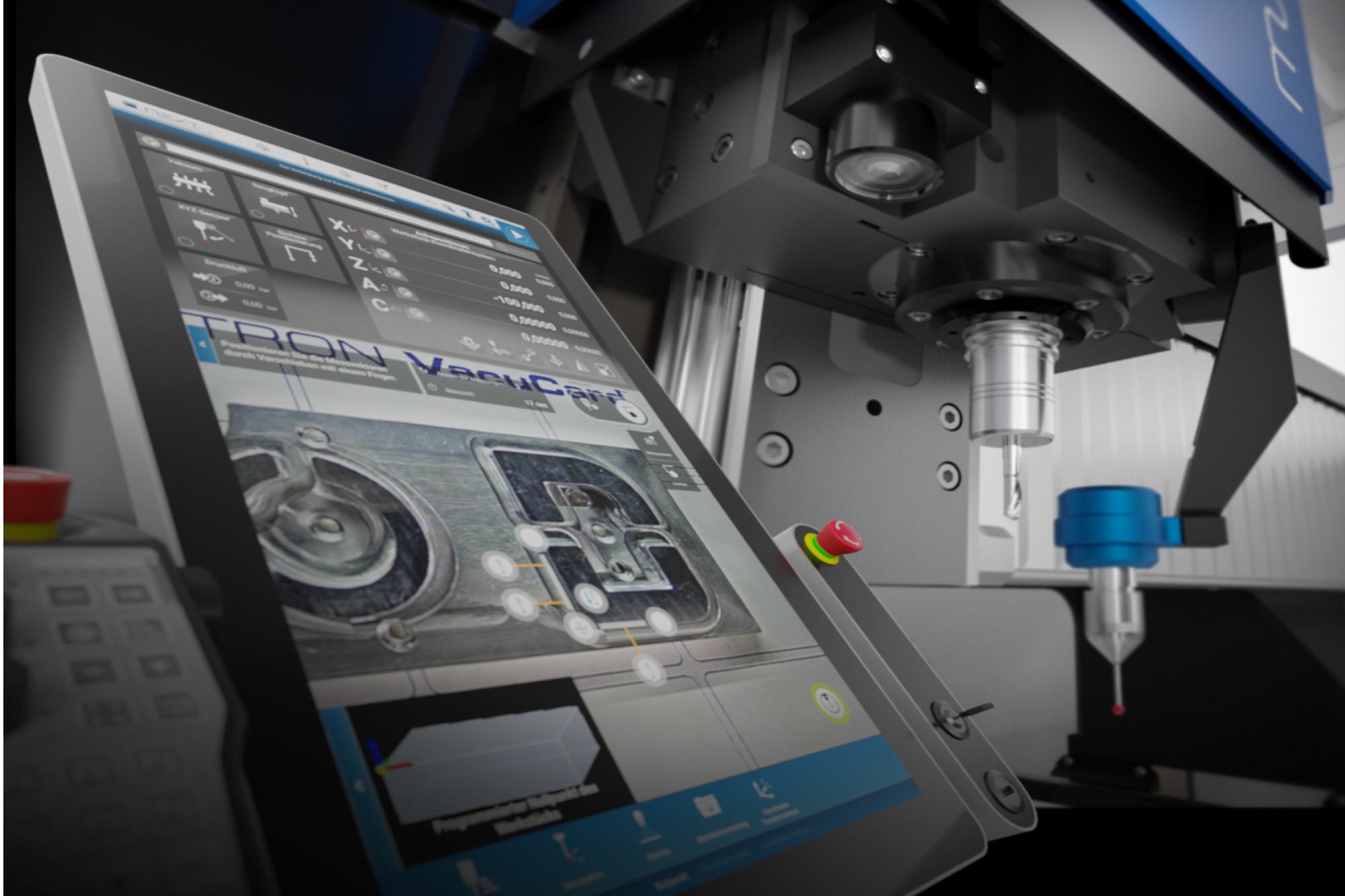

“The X Platform by Exor is the most complete enterprise ready Industry 4.0 platform that enables one to rapidly develop new applications of smart connected devices for clients. Being such a complete platform Exor can help enable the application need to implement Industry 4.0 plan no matter at what stage one is currently,” Arora claims.

Operating in industry sector since 1971, this vast experience coupled with continued multi-year world -class innovation allows Exor to control all stages of development, design and manufacturing over the following parts of the X Platform i.e. software, hardware, Cloud.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.