Right lubrication for your hot forging

By OEM Update Editorial December 10, 2018 1:44 pm IST

Lubrication plays an inevitable role in hot forging process to maintain quality and productivity. Hot forging process is performed at an extremly high temperature (up to 1250-degree C for steel, 360-degree C to 520-degree C for Al-alloys, 700-degree C to 800-degree C for Cu-alloys). These temperatures are necessary in order to avoid strain hardening of the metal during deformation. So, lubrication of forging process is not easy task; it depends on the right selection of lubricants for the right application areas to get the best results.

A lubricant for forging dies is a chemical compound that has a formulation that makes possible the forging process to be carried out within the limits and parameters considered by the forging industry.

Characteristics of ideal lubricants are as follows:

• Reduce the sliding friction between dies and work piece (load and energy requirement will be reduced)

• Works as a parting agent between die and work piece (prevents sticking)

• Works as an insulator

• It should develop a balanced gas pressure (specially in hammer forging with impression; this is called dieseling effect)

• Should be non-abrasive and non-corrosive

• Shouldn’t create smoke (pollution free)

• Availability with reasonable cost

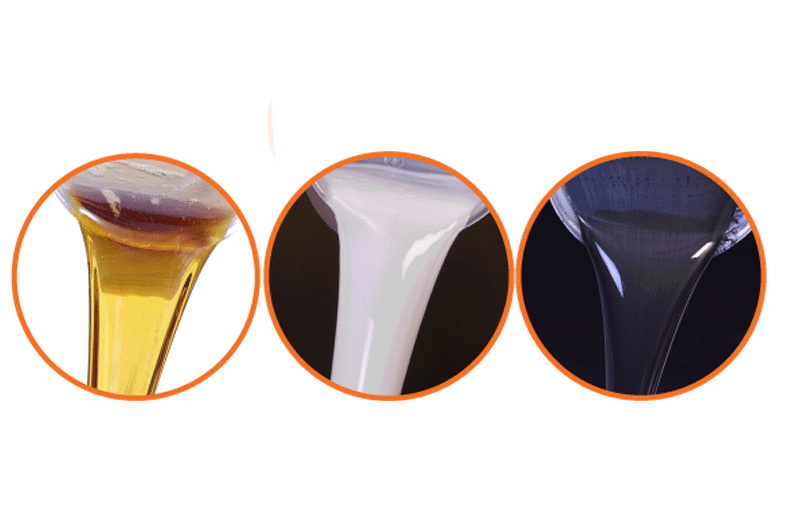

Depending upon application areas, profile and metallurgy of forging component, die lubricants can be divided into two major categories: water-based and oil-based. Both types are again divided into

two sub-categories – with graphite and without graphite.

• Water-based non-graphite lubricants: These are special water-soluble polymer-based lubricants. This lubricant is the best choice for shallow cavity dies. It is considered to be the most cost-effective solution due to its properties of excellent cooling along with lubrication properties.

• Oil based lubricant: According to your demand for the forging process of lubrication, the special additives are added to the graphite with the base of either base oil or vegetable oil. This is the way such suspensions are made. There are a few grades that come without graphite as well. Such lubricants have excellent release properties and provide better flow of material. This lubricant can be used for several purposes such as used in deep cavity hammer forgings, heavy stainless-steel forgings, critical brass and aluminum forgings, and deep extrusions.

About us:

Sunlube is one of the fast growing manufacturing houses based in Pune with their facility at Ahmed Nagar, Maharashtra. Young and dynamic Sandeep Gaikwad leads the Sunlube Team, and their solutions are used by large companies across the country.

Established in 2012, Sunlube continuously works towards the quality of its lubrication products. Sunlube’s manufacturing unit is located in Ahmednagar MIDC and the is expanding its reach to spread all over the country dealers and distributors currently located in Aurangabad, Rajkot, Bangalore, Chennai, Delhi and Rudrapur.

Authored article by:

Sandeep gaikwad

Sunlube India Private Limited

visit: www.sunlubtech.com

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.