Machine tool industry, on its toes

By OEM Update Editorial January 11, 2019 5:27 pm IST

An exclusive report on the trends in machine tools which keeps the machine tools industry on its toes to change it dimension as per the market behaviour.

The machine tool market in India is increasing day by day. As a result of the growing demand, the country is set to become a key player in terms of global machine tools industry and is likely to see substantial high-end machine tool manufacturing. It is largely expected that the platforms like ‘Make in India’ coupled with the growth in manufacturing are said to be the results of the growing demand in the machine tools sector.

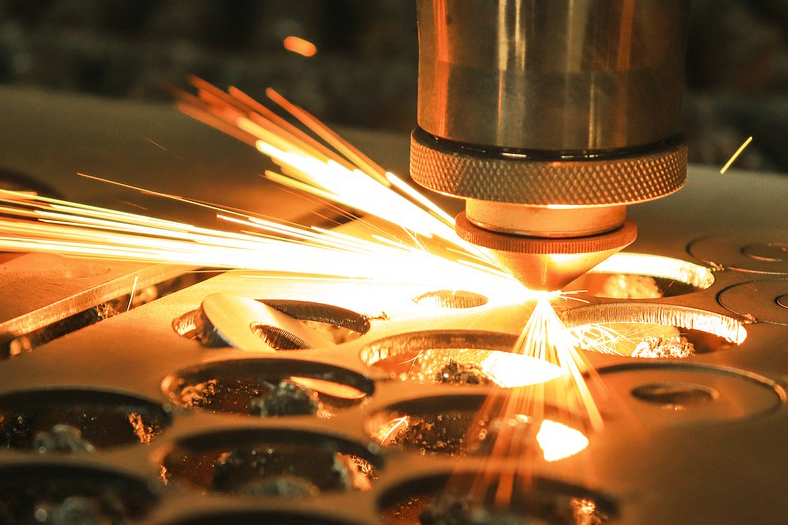

Machine tool industry needs continual improvement in productivity and costs to sustain itself in the global market. With Additive Manufacturing offering several advantages over CNC machining, there is a general belief that it would replace subtractive manufacturing process in selected areas. “Additive Manufacturing will also work together with CNC machines to deliver productive solutions. Manufacturers who have understood the benefits of this have merged these technologies to create ‘hybrid machines,’. In this process, the machine will undertake additive process as well as metal cutting process with quick changeover from metal cutting to additive process and vice versa,” says V. Anbu, Director General & CEO, IMTMA.

Core trends changing the machine tool industry

According to Keshav Khurana, Executive Director, Wohlhaupter India Pvt Ltd, three trends affecting the global machine tool industry are process automation, additive manufacturing and the rise of electric vehicles.

Process automation

The investment in process automation is expected to reach 120 billion dollars globally by 2019, according to market experts. High quality products with improved precision can be achieved with shorter lead times by automating production processes. Computer numerical control (CNC) is the latest trend in this sector. CNC machines in developed as well as developing economies have created a surge in production efficiency and improved quality in the machine tool industry.

Additive manufacturing

3D Printing has changed the dynamics of the industry and is used extensively in the automobile, defense and medical sectors. Additive manufacturing offers light-weight, cost-effective and quick solutions for concept validation.

Electric vehicles

Electric vehicles (EVs) are on the rise and every nation is experimenting with manufacturing innovations in order to get them commerciallyon the roads. Many would like to opine that with the advent of electric vehicles there may not be many opportunities for the machine tool sector, but I may argue that statement. Keshav says, ”Although internal combustion cars may be phased out over time and replaced by electric vehicles, hybrid vehicles will most likely ease the transformation for several years. I believe our industry will embrace the changes in the automotive sector and adjust accordingly by providing new machine tooling solutions. I am confident we will meet the changing demands of the automotive sector in the future as our industry has a strong history of innovation.”

Ajey Phatak, Marketing Manager, Beckhoff Automation, Pvt Ltd, states, “Industry has advanced significantly in hardware and software applications and this would continue with use of more computerised (PC based) machine controls. Automation of processes into manufacturing and engineering sectors will drive the industry. The indicative trends show preference of manufacturers towards increased machine performance, inclusion of smart features, highly automated andIoT ready machines.”

Globally, most of the machines use numerical controlled (CNC controlled functions), with PC based control and virtual HMI. Indian machine builders need to adapt swiftly to these trends.

According to Ajey, the various types of precision tools are used in the automobile and defence sector. Precision tools offer many advantages such as high quality products and great precision and the trend is towards using sophisticated controls to produce them. The advanced CNC functions of machines equipped with precision counting and measuring devices and with self-adjusting control systems will be preferred. Indian manufacturers who need to catch up with these trends very fast and implement complex controls using PC based control technology else they would not be able to compete in global markets. Technology companies have made huge advancement in software CNC which can enable manufacturers to customise these features in their machines.

However, the disruption brought in by increased preference to electric vehicles will create challenges but also newer opportunities for Indian industry where automation again will play a vital role for efficient processes.

Ajey says, “Robotic assisted machine tools are another trend that sees inroads in manufacturing industry. Use of collaborative robots is trend being analysed in India. We may see robotic arms replacing operators in complex and hazardous machining operations.”

Girish Modi, Director, 3 M software solutions, says, “In India, our machine tool industry is facing tough competition from China. They are struggling to match Chinese suppliers on time, cost and quality. Most of the tool manufacturers are trying for automation in design and manufacturing, reduce manual errors and trying to cut down cost.”

Foreign Direct Investment India (FDI)Foreign Direct Investment in India was introduced in 1991 under the Foreign Exchange Management Act (FEMA), driven by the then Finance Minister Manmohan Singh, Keshav acknowledges.India was ranked 11th position in the FDI Confidence Index 2018 released by global consultancy firm A T Kearney. It has slipped by three notches in 2018 as it was ranked 8th in 2017 and 9th in 2016.

The fall in India’s rankings may be due to challenges faced in implementation of the 2017 nationwide goods and services tax (GST) and the 2016 demonetisation initiative which disrupted business activity and weighed on economic growth. This may have deterred investors in the short term, but strong economic performance and the sheer size of the Indian market are important factors likely to attract investors in the future.

Keshav confirms, “For a developing economy, like that of India, FDI inflows play an important role in bridging the gap between domestic savings and investment as well as maintaining sustainable economic growth. The inward FDI is argued to have visible impact on the real economy through its effect on important macroeconomic variables.”

Rajesh Savergaonkar, BU Head, Grind Master, depicts India’s position via UNCTAD – United Nations Conference on Trade & Development

India is becoming a preferred destination for FDI as our domestic consumption is going high.With the manufacturing sector gathering momentum, helped by both services and agriculture sectors, and a robust consumption demand in the country making it an attractive investment destination. Ongoing govt. policy reforms in sectors ranging from single brand retail trading, civil aviation, real estate broking service and simplification of legal and regulatory system, has led India to move into the top 100 countries in the World Bank’s Ease of Doing Business global rankings.

MayankTripathi, Area Manager Sales North India, Hurco India says, “The confidence is a result of the Government’s Make in India initiative, which aims to boost investment in India’s manufacturing sector. Lots of new manufacturing hubs are developing in India. All the big giants from aviation and electronic industry are starting indigenous manufacturing. I will say India’s future is bright.”

Ajey adds, India was the highest ranked country in attracting Greenfield FDI in 2015 & 2016 but subsequently its ranking has dropped in 2017. India was ranked 11th position in the FDI Index 2018 released by FDI Report 2018 of Financial Times.

While discussing on the FDI topic, Girish includes, “In machine tool industry, most of the die and mold plants are putting up their plants in India. For example, VEM tools, one of the major mold manufacturers, had started operations in India two years back. However, now, for them, India’s manufacturing unit is giving better results than that in China. Lot of companies from electronic industry are now having their mold shops in India.”

Cost prevails over quality

Keshavconcludes, the manufacturing price war is not a healthy sign at all for prospects striving to bring quality products to consumers. While there may be an initial investment in high quality machining equipment, consumers realise quickly it is more expensive in the long run to purchase cheap tools.

Manufacturers who have understood the benefits of this have merged these technologies to create ‘hybrid machines’

V. Anbu, Director General & CEO, IMTMA

We will meet the changing demands of the automotive sector in the future as our industry has a strong history of innovation

Keshav Khurana, executive director of Wohlhaupter India Pvt Ltd

Robotic assisted machine tools are another trend that sees inroads in manufacturing industry.

Ajey Phatak, Marketing Manager, Beckhoff Automation, Pvt Ltd

Most of the tool manufacturers are trying for automation in design and manufacturing, reduce manual errors and trying to cut down cost.

Girish Modi, Director, 3 M software solutions

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.