Automatic loading system: Defining tool accuracy

By OEM Update Editorial June 18, 2019 12:55 pm IST

Winfried Przybyl, Director-India & Russia, United Grinding Group Management AG, in an interaction with Athira Bejoy of OEM Update discusses how United Grinding is moulding its way of working to cater the needs of price-sensitive India.

Will a product manufactured in India in lieu with Make in India will give the exhibit the same standard as of European production?

With Make in India, the target was to produce as much as possible in India. But, right now, I think, the only sector that is reacting much to it, is the automotive industry.

It is absolutely possible that product produced in India can be of high quality. India has abundance knowledge and people. It is just a matter of time and effort and also customer requests that will play a big role. However, one major issue is, Indians are mainly concerned about low cost products and not that eager to invest in high quality products. What needs to be understood here is, that, low priced parts may only bring in low quality products.

I believe, however, that when the pressure to manufacture and distribute high quality products increases, India will rise to the occasion and get it done. Some of the local competitors are already producing high quality machines which comply with the global standards. But, majority of them are still to be made aware of the quality parameters of products.

Is Digital India being really understood by the Indian market?

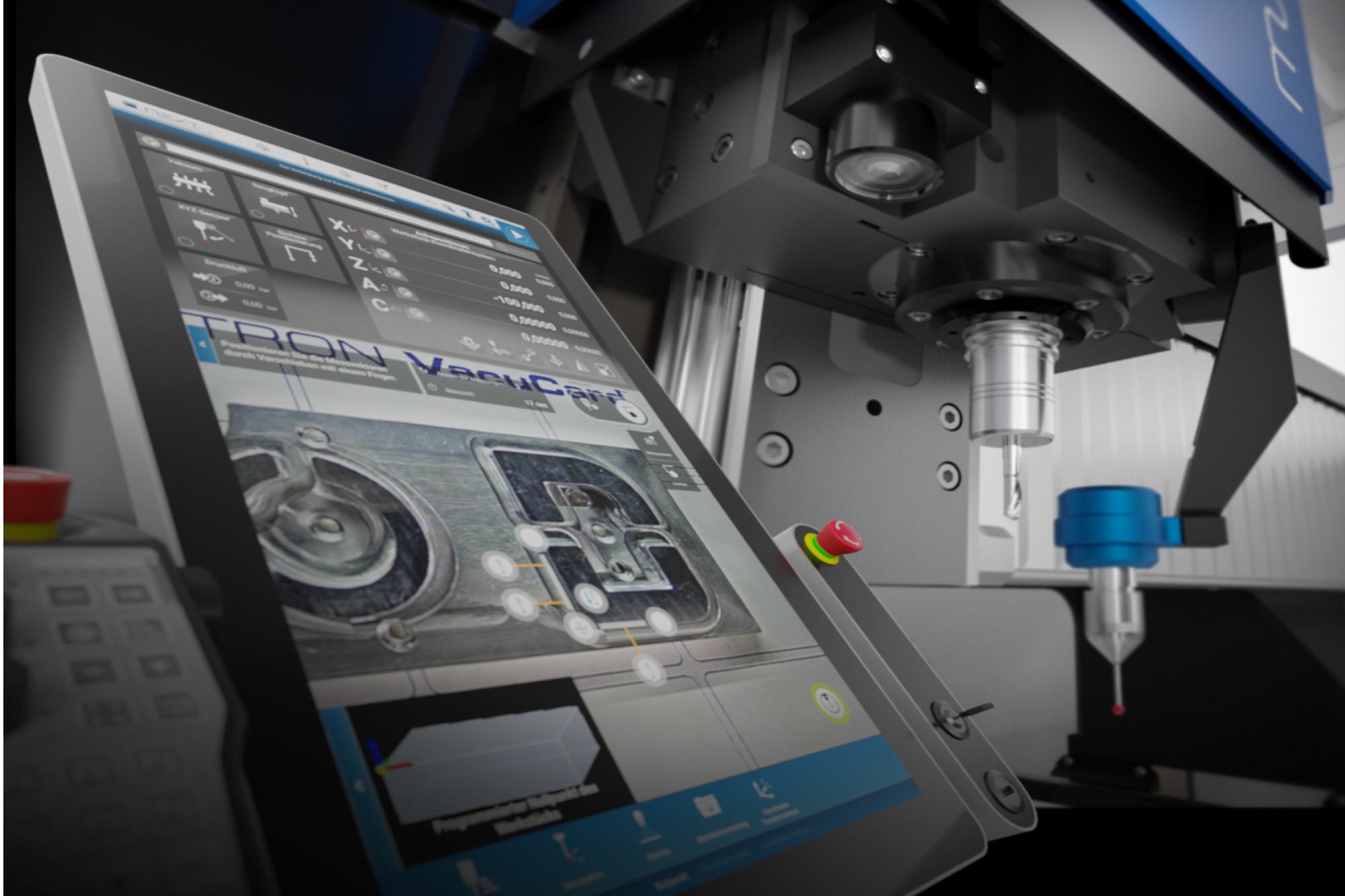

Automation and going digital are the terms that are yet to find its roots in India. When we approach a client and show an automated machine; the feedback we generally get is that ‘why choose an automated machine when we have manual machines easily available’. What the client does not realise is, that, If a machine runs constantly, the accuracy of the tool is much higher and if opted for the manual machines, the operator will influence the running quality of the machine. In case of manual machines, there are interruptions by the operator, waiting for the machine to stop, to cool down and then change the toolbox, etc. means, influencing the tolerance of the machines. If the operator goes for lunch, say, for an hour, then the machine is idling. If you have a loading system on the machine, it will continue to run 24 hours a day. This will give you much higher quality and much higher efficiency out of your machine. The price of a machine should be a secondary request and the customer should understand to get better performance machine with automatic loading system.

How is United Grinding implementing sustainable manufacturing?

We have a special team that looks into or investigate what can be done to reduce power consumption in our machines. However, as far as Indian customers are concerned, they look for machines that are bulky and has big motors. They think that if they buy the strongest machines, even though they are not needed at all, then only they will get product or a decent RoI.

Production companies who produce machine tools have huge machines with spindle motor, even though they don’t need them. There is absolutely no need to have strong motors on grinding if you need only a tool of 6mm diameter. It always comes down to what the customers’ requests are. If the customer requests for a big engine, then we provide one. But sometimes the customers need to reconsider on what are his needs and what he wants.

How do you evaluate working with India?Working with India means working with an additional pressure to find low cost solution. India is really driven by price. Being price sensitive pressurises us to produce low cost machines. This gives us the task of working on different possibilities to produce the customer-required product in a cheaper way.

Customer request is everything. If there are no demands and request from the customers, nobody would be pushed to re-consider his way of working. So, because of the customer pressure, we have reconsidered the way we do things; we need to pick the best way out of the lot. Every request from a customer is unique; so, when the market demands things, we need to reconsider our way of working.

How is United Grinding helping the Indian market?

Our machines are adjusted to fit in the Indian market. For the Indian market, we are just trying to reduce the cost for them. Whatever parts of the machine that needs to be of German quality, we import those from Germany and rest, like, the coolant devices or mist extractor are bought locally; that’s what our organisation in India is doing. This definitely help us in reducing the cost; thus, trying to help our customers and meet their needs. Grinding machines has grinding wheels which can also be bought locally. But we do need to consider the force and quality of the wheel being used. If we can produce only 10 tools with one grinding wheel, then it is not a good quality. If you can produce 100 with a similar grinding wheel, then we would prefer that one.

Indians recognise that United Grinding has high quality machines like walter and studer machines which they would definitely like to have; however, cost of these machines comes as a hindrance. Hence, lot of Indian customers are looking for second-hand machines. As a matter of fact, a lot of companies import used or old machines to India. So, there is a huge market for used walter and studer, second-hand machines in India which is also an advantage for us.

We do provide after-sales services locally. So, our people are ready to help such customers even if they are buying used machines from around the world. We get the machines installed, give them training, service support whenever something is broken. A big part of our order is coming from our customer care side.

Customer request is everything. If there are no demands and request from the customers, nobody would be pushed to re-consider his way of working

Winfried Przybyl, Director-India & Russia, United Grinding Group Management AG

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.