Garuda Aerospace readies defence drone hub in Chennai

By Staff Report September 1, 2025 7:42 pm IST

Garuda Aerospace is readying a new defence drone hub in Chennai for deeper R&D and advanced manufacturing practices, while gearing up for an IPO to drive global expansion and exports. In this exclusive interview, Agnishwar Jayaprakash, Founder and CEO of Garuda Aerospace, shares insights about their manufacturing facility and how they are levelling it up for the global market.

How is your manufacturing facility designed to handle scale while ensuring quality and cost efficiency in drone production?

Our manufacturing facility is highly scalable, maintaining stringent quality control and cost efficiency through a modular production line. Automation of repetitive tasks enhances speed and precision, complements quality management with rigorous testing, and reduces labour costs. Optimising the supply chain and lean manufacturing principles minimises waste and operational overhead, enabling us to ramp up production while keeping costs competitive.

How are you addressing supply chain challenges, especially around sourcing electronics, sensors, and aerospace-grade materials?

We are focusing on building a resilient and largely indigenous sourcing network. We have made significant progress in reducing reliance on foreign components by creating a strong ecosystem of local vendors for electronics, sensors, and aerospace-grade materials. This is achieved through strategic partnerships and a dedicated R&D effort to develop and qualify Indian-made alternatives. We employ a multi-sourcing strategy for critical components to mitigate risks associated with geopolitical events or the failure of a single supplier. By maintaining a buffer stock of essential parts and leveraging long-term contracts with key suppliers, we keep a stable and predictable flow of materials.

How much of Garuda’s drone hardware is indigenously designed and manufactured in India, and what steps are being taken to reduce import dependency?

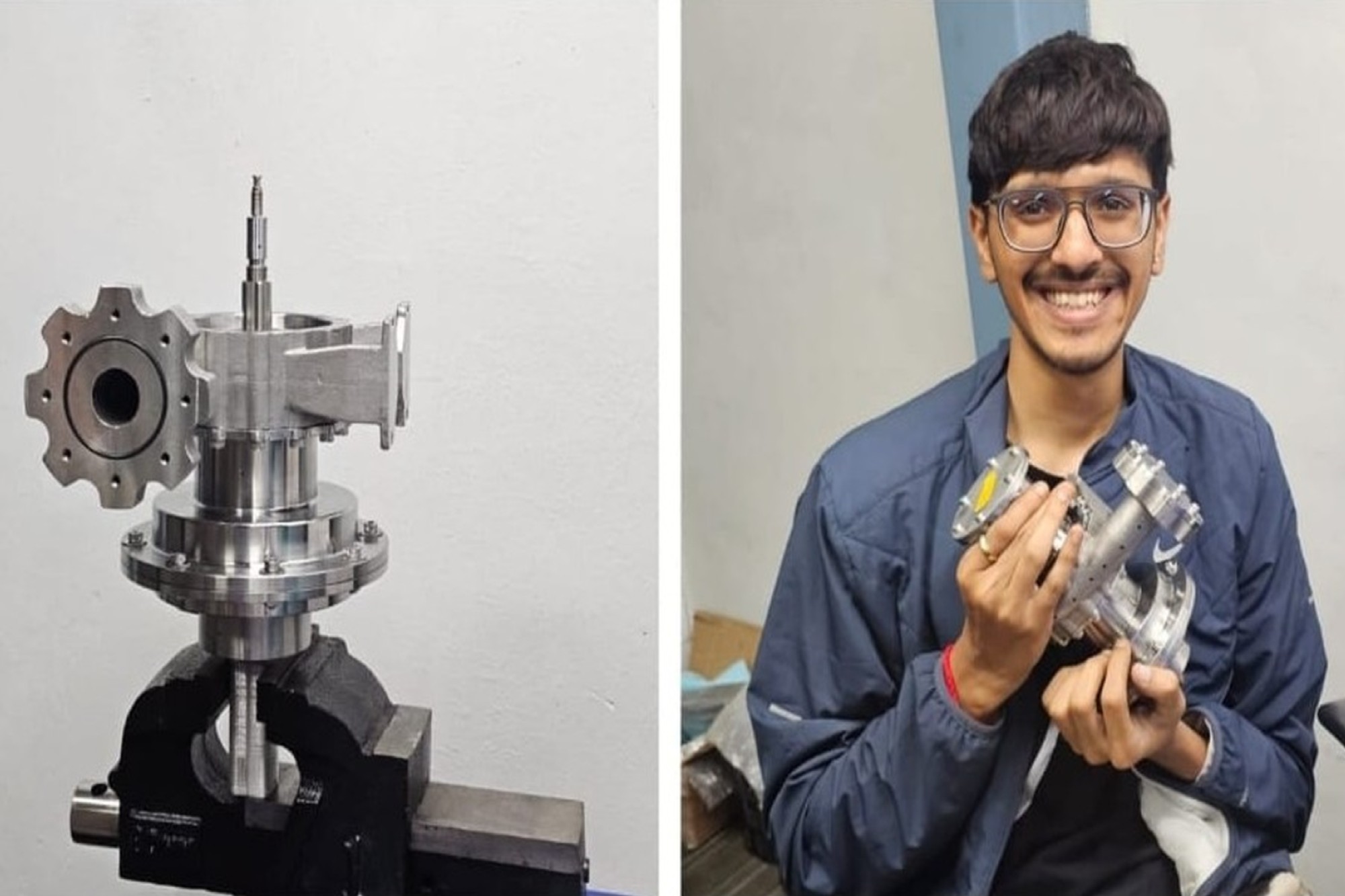

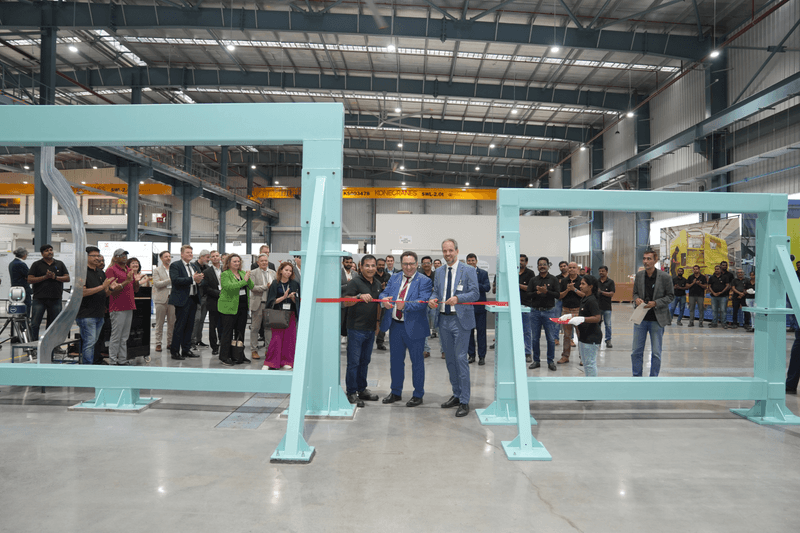

We are deeply committed to the ‘Atmanirbhar Bharat’ (self-reliant India) initiative, with a significant portion of our drone hardware indigenously designed and manufactured. Our in-house R&D team drives innovation, developing proprietary designs for drone frames, flight controllers, and payloads, and actively reducing import dependency by collaborating with local partners. The new Defence Drone Facility in Chennai serves as a complete ecosystem for advanced UAV design, R&D, and production. We collaborate with institutions such as ISRO and the Indian Army to co-develop mission-specific technologies, thereby further accelerating indigenisation and maintaining high standards for both civilian and military applications.

What role is Garuda Aerospace playing in shaping India’s drone ecosystem and policy?

We are actively collaborating with the government and regulatory bodies, such as the Directorate General of Civil Aviation (DGCA), to provide valuable feedback and insights that inform the development of clear and enabling policies. As one of the first companies to receive DGCA Type Certification and a Remote Pilot Training Organisation (RPTO) license, Garuda Aerospace has set a benchmark for industry standards and compliance. We are also promoting the use of drones across various sectors, including agriculture, defence, smart cities, and logistics, through partnerships with government ministries and public sector undertakings. We also support initiatives such as the ‘Kisan Drone Yatra’ and the establishment of training programs for drone pilots, including those for women and military veterans.

Are you adopting Industry 4.0 practices, such as IoT-enabled monitoring, digital twins, or AI-driven quality checks, in your production lines?

Our manufacturing facility is equipped with IoT-enabled monitoring systems that provide real-time data on every stage of production, from component assembly to final testing. This data is used for AI-driven quality checks, enabling predictive maintenance and the immediate identification of any deviations from quality standards. We are also exploring the use of digital twins, which are virtual replicas of physical production lines, to simulate and optimise manufacturing processes before they are implemented in the real world. This approach increases efficiency and reduces time-to-market, while maintaining a consistent and high-quality product. By integrating these advanced technologies, we are building a smart, agile, and highly efficient manufacturing ecosystem that is ready for the demands of the future.

How does your manufacturing facility balance R&D prototyping with large-scale production needs?

We have established an innovation pipeline that separates R&D and prototyping from the main manufacturing lines so engineers can experiment freely. Once prototypes are finalised, a seamless process integrates them into large-scale production, including design transfer and training the production team. This ensures continuous innovation without impacting manufacturing efficiency or product quality.

As you plan global market expansion, how are you aligning manufacturing capabilities to meet export demand and regulatory requirements? Are you planning to launch an IPO?

As we plan to expand into the global market, we are aligning our manufacturing capabilities to meet international export demand and diverse regulatory requirements. We have recently secured an export license, which is a significant step toward penetrating markets in the U.S., Australia, and the Middle East. Our manufacturing processes are designed to be flexible, allowing for modifications to meet specific international standards and certifications. We are partnering with global giants and establishing a presence in new markets to build a robust export pipeline.

We have completed several funding rounds, including a Series A and Series B, with backing from prominent investors and venture capitalists. These investments have been crucial in scaling up operations, expanding the drone fleet, and enhancing R&D capabilities. We are preparing for a public listing, with an IPO planned to raise significant capital. The proceeds from this will be used for several strategic initiatives, including further expansion of manufacturing facilities, deepening R&D efforts, and strengthening the company’s presence in international markets.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.