Automation in manufacturing production lines using Cobots

By Staff Report August 9, 2024 6:54 pm IST

Automation in manufacturing has ushered in a new era of efficiency and precision, fundamentally altering how production lines operate. At the heart of this transformation are collaborative robots or cobots, which work alongside human workers to optimise various industrial processes.

The benefits of automation and cobots are numerous, ranging from enhanced productivity and cost savings to improved workplace safety and product quality.

Efficiency and precision

One of the most significant advantages of automation and cobots in production lines is increased efficiency and precision. Cobots perform repetitive tasks with accuracy that human workers cannot achieve. This precision leads to faster production rates and consistent output quality, which is crucial for maintaining high standards in manufacturing. By reducing errors, companies can minimise waste and rework, lowering operational costs.

Cost savings and flexibility

Automation and cobots also offer substantial cost savings. By integrating these technologies into production lines, companies can reduce labour costs. The cobots can take over repetitive and mundane tasks, allowing human workers to focus on more complex and value-added activities. This optimises workforce utilisation and reduces the overall operational costs associated with human labour.

Moreover, cobots provide the flexibility to adapt quickly to different tasks and products. Unlike traditional industrial robots, cobots can be reprogrammed and redeployed to handle various processes, making them ideal for small and medium-sized enterprises (SMEs) that remain agile and responsive to market changes. This adaptability enables SMEs to innovate and scale their operations efficiently, enhancing their competitiveness in the industrial manufacturing sector.

Enhancing workplace safety and ergonomics

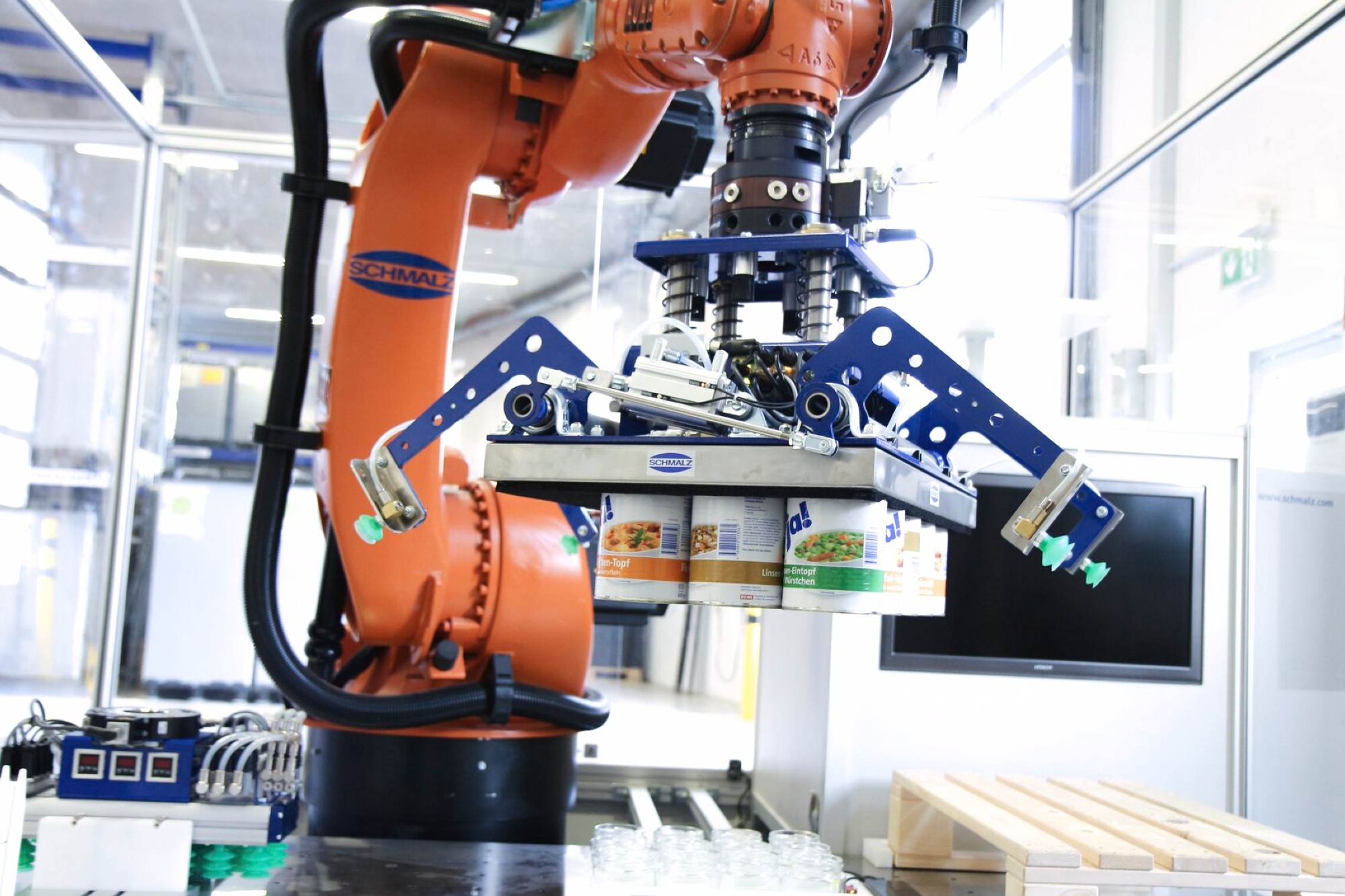

Safety is a principal concern in manufacturing settings, and cobots improve workplace safety and ergonomics. Cobots are designed to work alongside humans, taking on tasks that may be hazardous or physically strenuous. By handling heavy lifting, repetitive motions, and dangerous tasks, cobots reduce the risk of workplace injuries and ergonomic issues.

For instance, in environments where workers are exposed to harmful substances or extreme conditions, cobots can perform the tasks while human workers oversee the operations from a safe distance. This collaboration protects workers and enhances overall productivity by ensuring operations continue smoothly without compromising safety.

Advantages for SMEsCobots offer distinct advantages for SMEs, which often operate with limited resources and need to maximise efficiency. The cobot integration into industrial processes helps SMEs achieve increased efficiency, flexibility, and precision. By automating repetitive tasks, SMEs can reduce labour costs and focus on improving product quality by automating repetitive tasks. It allows them to compete more effectively with larger enterprises.

Additionally, cobots allow SMEs to scale their operations without capital investment. As market demands fluctuate, SMEs can reconfigure their cobots to meet new production requirements and ensure they remain competitive and responsive to customer needs.

Overcoming implementation challenges

While the benefits of automation and cobots are clear, companies may face challenges when implementing these technologies. Integrating AI and IoT into existing production processes can be complex, requiring investment in infrastructure and training. Data privacy concerns and cybersecurity threats are also critical issues for the safe use of these technologies.

Furthermore, employees accustomed to traditional methods may resist change. Companies should invest in training and education to help their workforce adapt to new technologies and workflows. By addressing these challenges, companies can unlock the full potential of automation and cobots in their production lines.

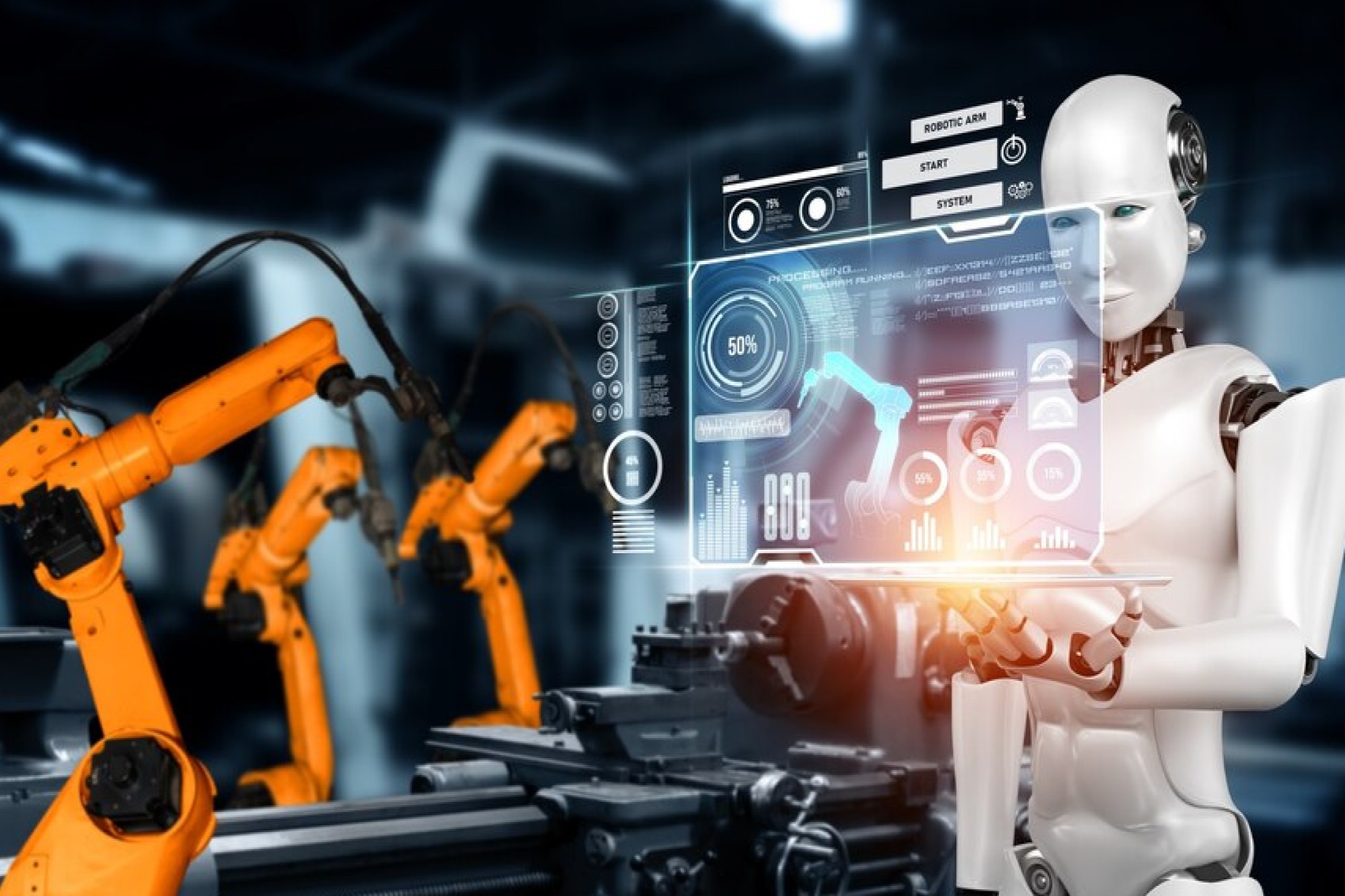

Technological advancements driving evolution

Continuous advancements in technology drive the evolution of cobots. It can be improved sensors for better spatial awareness and enhanced AI algorithms for Smarter decision-making. The advancements in collaborative technologies like force and torque sensors make cobots more capable and versatile. Additionally, developments in machine learning enable cobots to learn from their interactions and adapt to changing production needs, further enhancing their flexibility and responsiveness.

Conclusion

In conclusion, automation and cobots in production lines offer numerous benefits. These include increased efficiency, cost savings, improved safety, and enhanced competitiveness, particularly for SMEs. While there are implementation challenges, the ongoing advancements in technology continue to drive the evolution of cobots, making them an indispensable part of modern manufacturing. By embracing these technologies, companies can position themselves for success in an increasingly automated and competitive industrial landscape.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.