Automation in pharma plants

By admin April 23, 2011 9:00 am IST

Automation is the way of increasing quantity and quality of pharmaceutical products. M Damodar, Associate Director (IT & BPE) at Dr. Reddy’s Laboratories highlights the importance of automation in pharma plants and different steps involve

Automation of pharmaceuticals plants is the need of the hour given the increase in productivity and to ensure the supply of high quality products. The generic drug growth and spending patterns in the emerging markets has increased the demand for pharma products. At the same time creating current Good Manufacturing Practices (cGMP) and Federal Drug Authorities (FDA) approved plants which took the trend for plant automation. The debate to automate the manufacturing process began two decades ago, when, in 1990’s, the main focus was to reduce the manpower. This change for automation’s priority triggered heated arguments and negotiations with trade unions. Further, the need of manpower replacement has evolved and both categories of pharmaceutical products – prescription dosage (Rx) and Over-the-Counter (OTC) medicines have shown an increase in demand year-over-year because of the impending patent expiry for Rx and consumer awareness for OTC products. Therefore it became evident that automation would address the increase in productivity and also deliver quality products to the end customer. The pharma companies operating in the highly competitive generic market focus not only on regulatory compliance, quality and traceability but also look for reducing cost and increase inventory turns. The need of quality products is to meet the regulatory requirements of the highly regulated markets which is as per the standards of 21 CFR Part 11 that indicates, every batch produced should have digital signature and have the traceability / audit trail.

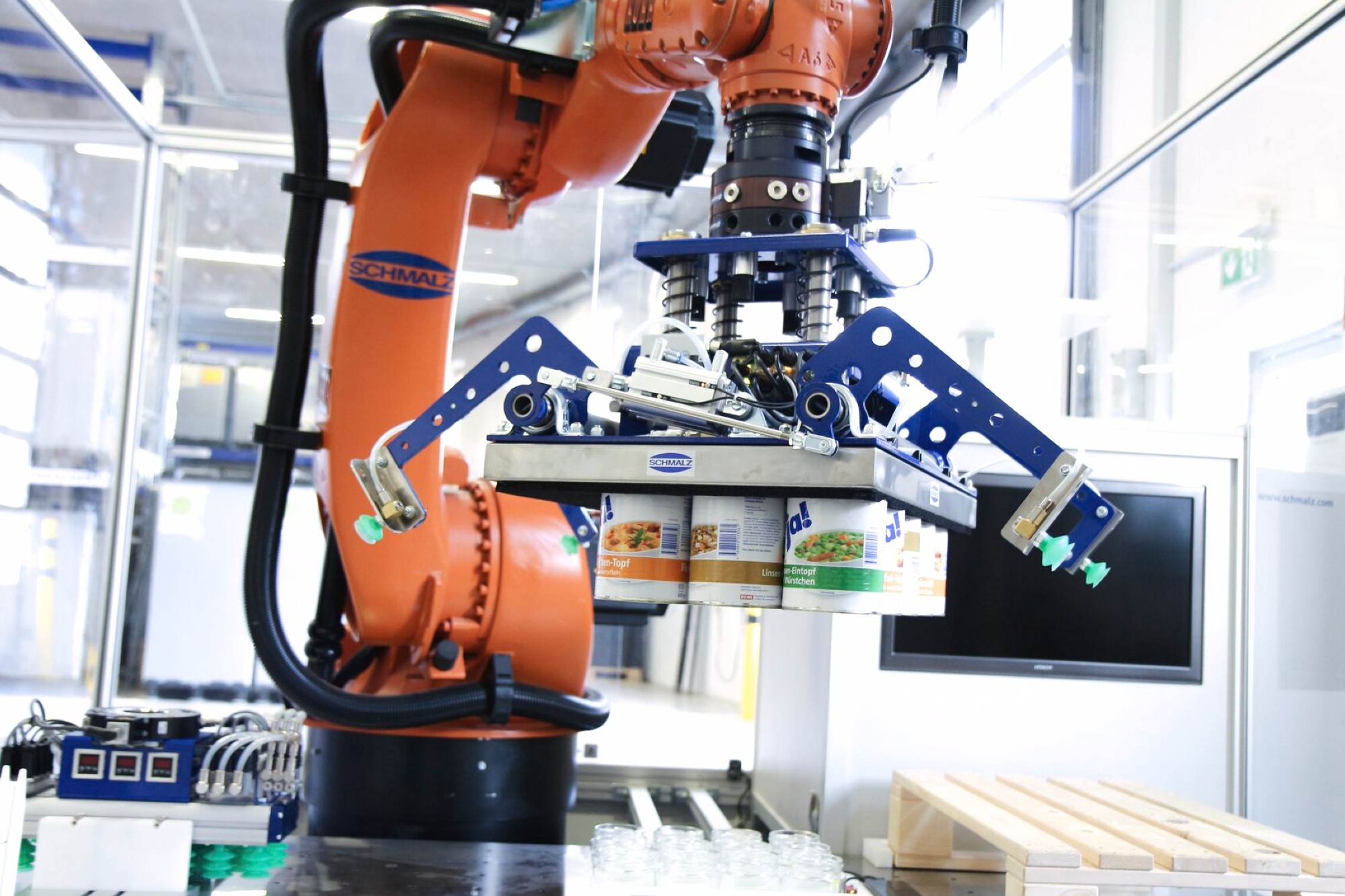

Automation in a pharma plant starts from the process of dispensing the raw material from the warehouse to packaging of the product which is the final stage for manufacturing.

Stage 1

Once the raw materials are received in the warehouse, they are unloaded by forklifts or through rolling conveyors which end at weighing machines in a quarantine area. Soft touch display pad recordings of the weighing machines are integrated with a printer and an ERP application so that an automated receipt is created for the material and ‘Under-test’ labels are printed for quality check. Near Infra-Red (NIR) is used for material identification and integrated with Spectrograph. The master specification of every material is maintained so that when NIR is used for identification, automatically it matches the specification, sampling procedure to results recording is managed through Laboratory Information Management System (LIMS) and finally the approved stock is moved to unrestricted use with a Barcode.

Stage 2

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.