Digitalisation is a key focus at EMO Hannover 2025

By Staff Report July 18, 2025 3:57 pm IST

As EMO Hannover 2025 marks its 50th anniversary, the spotlight is firmly on digitalisation and AI. From data-driven production to predictive maintenance and workforce support, the trade fair will showcase how smart technologies are reshaping manufacturing for greater efficiency.

Digitalisation in manufacturing continues to drive technical development and innovation, making it a key topic at EMO Hannover 2025. Despite its long history, which dates back to the advent of CNC systems in the 1960s, digitalisation remains critical in modern manufacturing. EMO Hannover, which is celebrating its 50th year, continues to represent these continual advancements.

Laying the Foundation for Digital Transformation

“It is always a good idea for companies to first gain an overview of which applications are relevant for them,” says Dr. Markus Heering, Executive Director of VDW (German Machine Tool Builders’ Association), which organises EMO. He emphasises that establishing transparency through targeted data collection and exchange is an important first step.

Connecting Machines with Standards

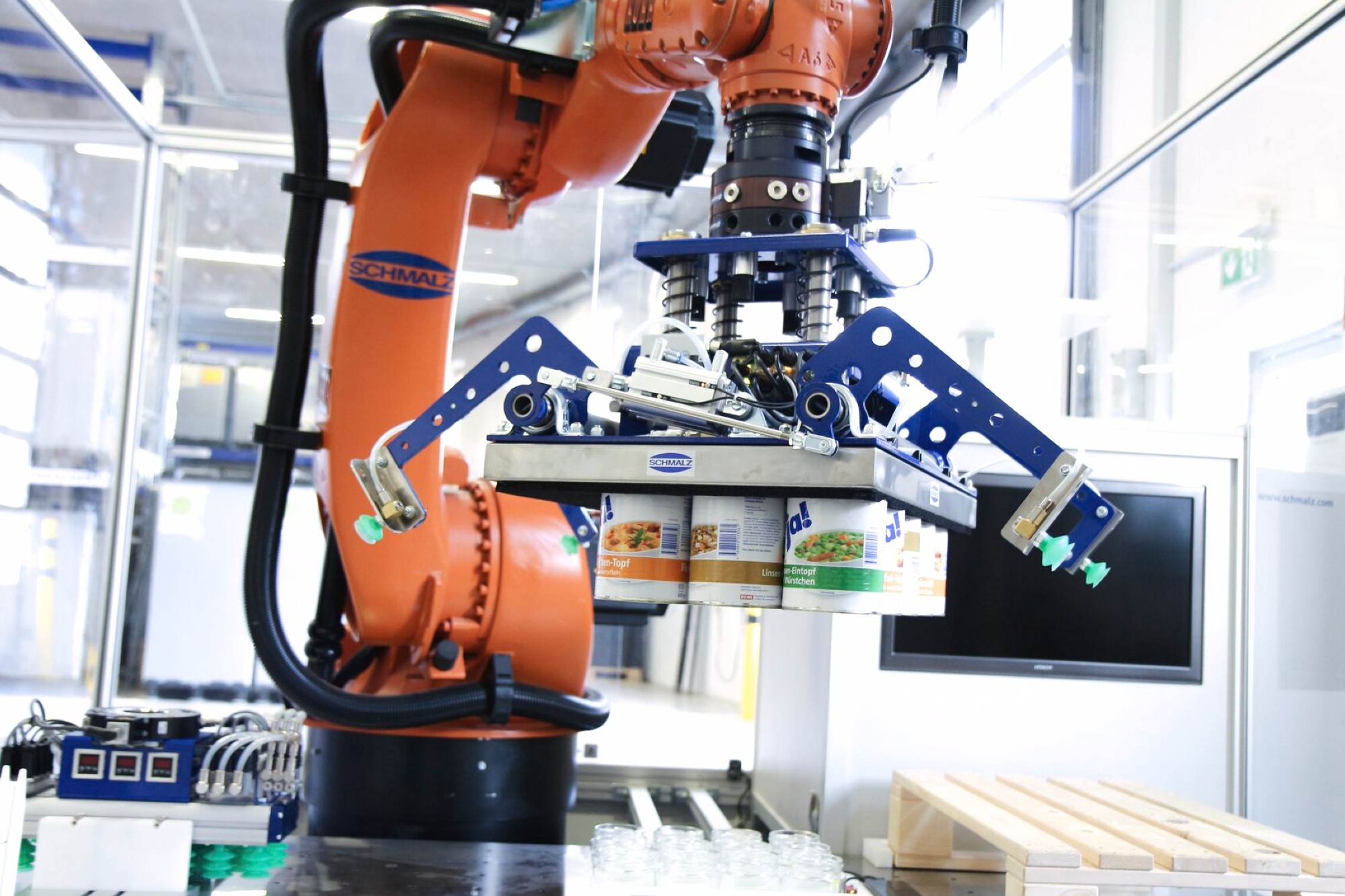

Modern machines are completely digitalised mechatronic systems. Building a closed data environment, such as a private cloud, necessitates the use of open, standardised interfaces to facilitate communication between new and existing devices, including those from various manufacturers. At EMO Hannover 2025, the umati (universal machine technology interface) effort will showcase the benefits of standardised machine networking.

Analysing vast amounts of data enables production optimisation, early error identification, and efficient resource utilisation, all of which contribute to increased global competitiveness.

Applications, Sustainability, and AI Integration

Digitalisation increases product customisation and flexibility to market demands, including mass customisation. It also promotes sustainability. “Optimised process control helps to better exploit the potential of a machine and use resources more efficiently,” says Professor Dr. Christian Brecher of the Fraunhofer Institute for Production Technology (IPT). Digital tools contribute to the circular economy by tracking resources and encouraging reuse.

Artificial intelligence (AI) improves operations by finding patterns that suggest system faults, allowing for predictive maintenance. AI may also analyse processes in real time and provide recommendations to cut energy use.

Addressing the Skilled Worker ShortageThe shortage of skilled workers will be a prominent issue at EMO 2025. AI-powered support systems are being investigated to help retain operational knowledge, aid less experienced employees, and provide training. The AI + Digitalisation Area and the AI Hub at EMO2025 will provide solutions and professional insights for incorporating AI into industrial workflows.

Preview of Exhibitor Solutions

Leading up to EMO in September, exhibitors will present digital and AI-based innovations on the “Made for AI & Digitalisation.”

To learn more, visit: https://emo-hannover.com/ai-and-digitization

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.