Improve real life through virtual worlds

By Staff Report June 13, 2025 6:03 pm IST

Dassault Systèmes provides virtual worlds to enhance real life with their 3DEXPERIENCE platform, which conceives innovative software solutions for 3D modelling, simulation, information intelligence, and collaboration, bringing them to life. Ravikiran Pothukuchi of Dassault Systèmes shares how their 3DEXPERIENCE platform is truly the face of smart manufacturing and driving Industry 4.0 adoption.

Dassault Systèmes has been a key player in providing innovative digital solutions to industries. How do platforms like CATIA, DELMIA, and ENOVIA integrate into smart manufacturing ecosystems and support product lifecycle management?

Dassault Systèmes’ CATIA, DELMIA, and ENOVIA applications are integral to the 3DEXPERIENCE platform, enabling smart manufacturing and effective product lifecycle management. CATIA is used for product design and engineering, supporting everything from conceptual development to detailed modelling. It supports model-based systems engineering and simulation-driven design, ensuring that products are optimised for performance and manufacturability. CATIA integrates with DELMIA to validate designs that can be efficiently produced within real-world manufacturing constraints.

DELMIA focuses on three key aspects of manufacturing. DELMIA’s Digital Manufacturing (DM) applications allow manufacturers to simulate, plan, and optimise production processes before implementation. It supports virtual commissioning and real-time monitoring, utilising IoT and analytics to enhance efficiency. DELMIA DM aligns engineering designs and manufacturing processes, managing manufacturing bills of materials (MBOMs) and process plans to maintain consistency and traceability. DELMIA’s Planning & Optimisation Apps help organisations to carry out their Enterprise Business Planning (S&OP, APS) from Demand to Distribution with a rich and powerful optimisation engine. Finally, DELMIA’s Manufacturing Operations Management (MOM) Applications monitor shop floor execution in real-time to maintain traceability, genealogy, quality, and maintenance.

ENOVIA is collaborative and manages data. It manages product data, configurations, and project timelines while supporting change management, compliance tracking, and lifecycle governance. ENOVIA enables cross-functional collaboration and ensures that stakeholders are aligned throughout the product lifecycle. In short, ENOVIA is an Enterprise IP & Knowledge management platform powered by NETVIBES’ powerful Analytics engine to provide insights into every facet of the Product Lifecycle.

How does Dassault Systèmes help manufacturers adopt Industry 4.0 technologies such as AI, IoT, and cloud computing to drive automation and data-driven decision-making? Is the same approach followed for MSMEs?

We support manufacturers through our unified 3DEXPERIENCE platform, a digital foundation for smart manufacturing. The platform is available on the cloud, making it accessible and scalable for companies of all sizes. This cloud-based approach eliminates the need for heavy IT infrastructure, enabling real-time collaboration, streamlined deployment, and integration across global operations. For manufacturers, especially MSMEs, this reduces upfront costs and simplifies the adoption of advanced technologies. AI is embedded throughout our solutions to enhance automation and data-driven decision-making.

For MSMEs, we focus on accessibility and scalability. We offer modular, industry-specific applications and subscription-based pricing models, allowing smaller firms to adopt only the tools they need. Additionally, we collaborate with local partners and innovation hubs to provide training, support, and implementation services, helping MSMEs overcome barriers to digital transformation. This democratised approach ensures that even small manufacturers can leverage Industry 4.0 technologies to enhance productivity, agility, and competitiveness in a rapidly evolving industrial landscape.

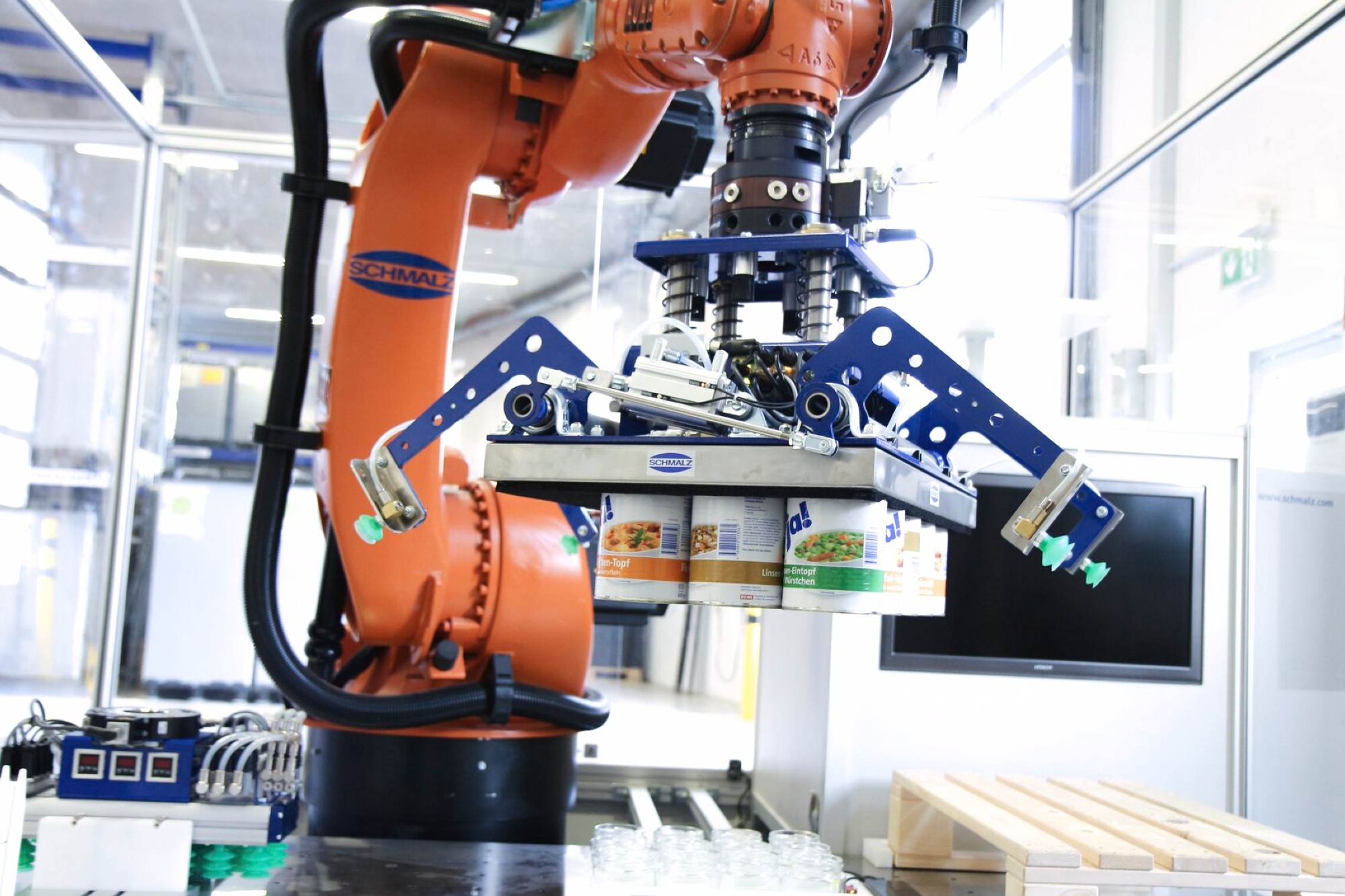

As global supply chains face disruptions, how do your platforms help manufacturers enhance supply chain resilience, particularly in managing complex supplier networks?

Our platforms help manufacturers strengthen supply chain resilience by using virtual twin technology to anticipate and respond to disruptions. With AI-driven part standardisation, companies can quickly identify alternative components and suppliers, reducing dependency on single sources. Virtual twins of factory systems perform real-time simulations and reschedule operations, ensuring agility in the face of unforeseen disruptions. This is critical in regulated sectors, such as aerospace, where export controls and localisation policies influence sourcing. The 3DEXPERIENCE platform enhances visibility, collaboration, and adaptability across complex supplier networks, keeping production on track and businesses future-ready.

Dassault Systèmes helps manufacturers enhance supply chain resilience, particularly in managing complex supplier networks, through its integrated 3DEXPERIENCE platform. This platform offers end-to-end visibility, collaboration, and risk management tools.

The platform enables companies to create virtual twins of their supply chains, allowing them to simulate disruptions, evaluate alternative sourcing strategies, and optimise logistics in real time. It supports multi-tier supplier mapping, helping businesses understand dependencies and vulnerabilities across their entire network, not just direct suppliers.

With built-in AI and analytics, manufacturers can forecast demand more accurately, monitor supplier performance, and identify early warning signs of potential disruptions. The platform also facilitates collaborative planning across global teams and suppliers, ensuring faster response and recovery during crises.

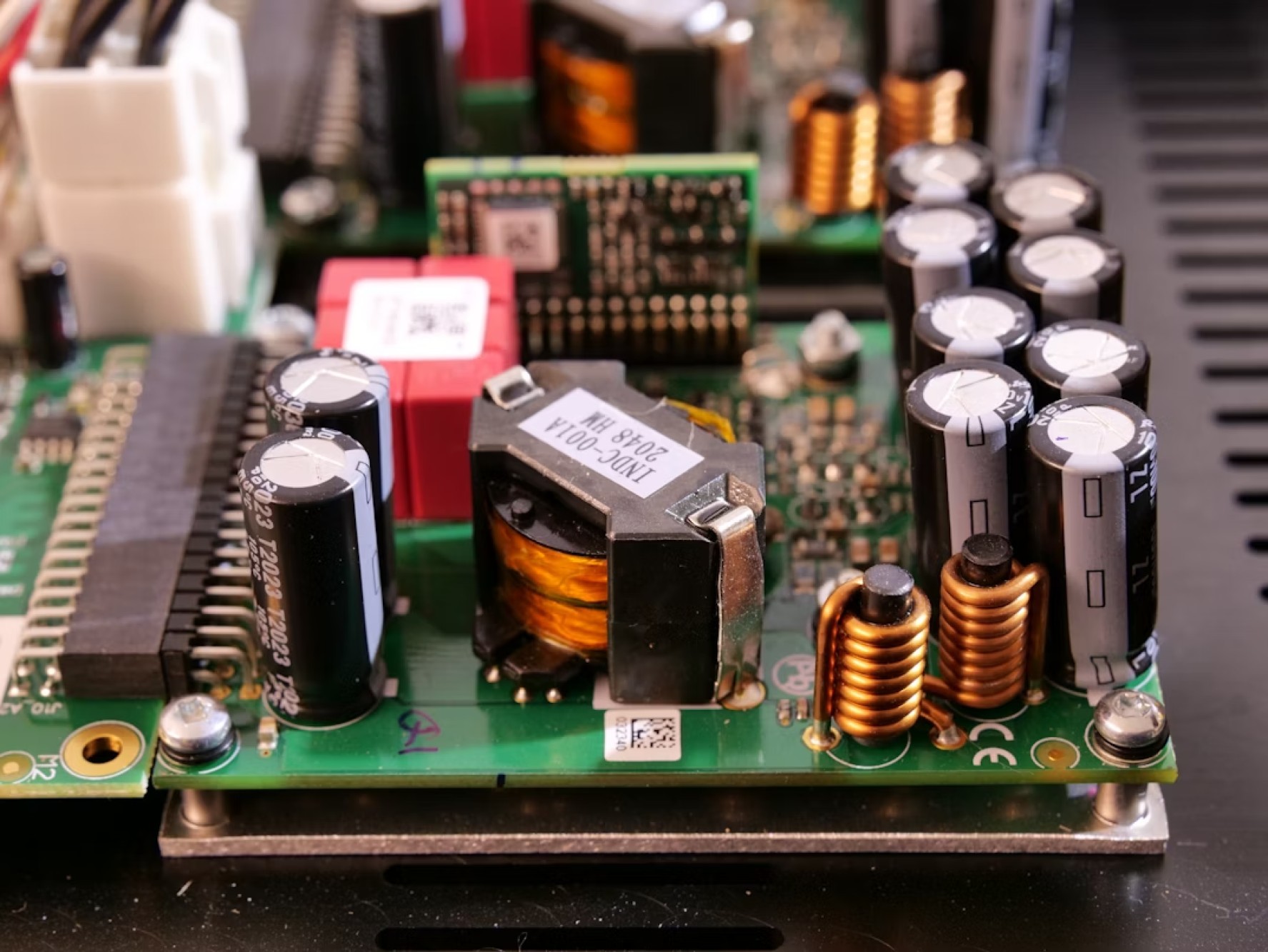

As automation advances rapidly and generates vast amounts of data, how do your solutions incorporate feedback mechanisms to strengthen and ensure cybersecurity?

As automation advances and connected systems generate vast volumes of data, we ensure cybersecurity through a layered approach embedded within the 3DEXPERIENCE platform. The platform is designed with secure-by-design principles, incorporating continuous feedback loops from user behaviour, system performance, and threat intelligence.

Real-time data monitoring and analytics enable the early detection of anomalies, while built-in feedback mechanisms help identify vulnerabilities and dynamically adapt security protocols. Role-based access control, data encryption, and traceability ensure that sensitive IP and operational data remain protected across the product lifecycle.

We also collaborate with industry partners and government frameworks to align with evolving global cybersecurity standards. With increasing cyber risks, particularly in the manufacturing and critical infrastructure sectors, the 3DEXPERIENCE platform enables customers to proactively manage threats, maintain operational continuity, and build resilience as digital transformation advances.

As automation scales and industrial systems become more connected, the need for built-in, adaptive cybersecurity is critical. Dassault Systèmes addresses this by embedding continuous feedback mechanisms into its 3DEXPERIENCE platform, enabling the monitoring, detection, and real-time response to threats.

The platform enables secure collaboration across design, engineering, and manufacturing by enforcing role-based access, encrypted data exchange, and end-to-end traceability. Feedback loops from user activity, system performance, and threat patterns help continuously refine security protocols and respond to anomalies swiftly. These insights inform policy adjustments, vulnerability patching, and risk-based access controls, thereby creating a self-improving defence framework.

By integrating cybersecurity as a core part of its platform architecture rather than treating it as an add-on, Dassault Systèmes ensures that enterprises can scale automation and data-driven innovation securely, even in highly regulated industries such as aerospace, defence, and life sciences.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.