Scale up automation processes through a multifaceted approach

By OEM Update Editorial June 5, 2024 4:47 pm IST

Sameer Gandhi, MD of OMRON Automation, India, shares insights on leveraging industrial automation technologies and addressing manufacturing challenges to enhance industry efficiency and scalability.

What industrial automation technologies will you suggest for scaling up manufacturing?

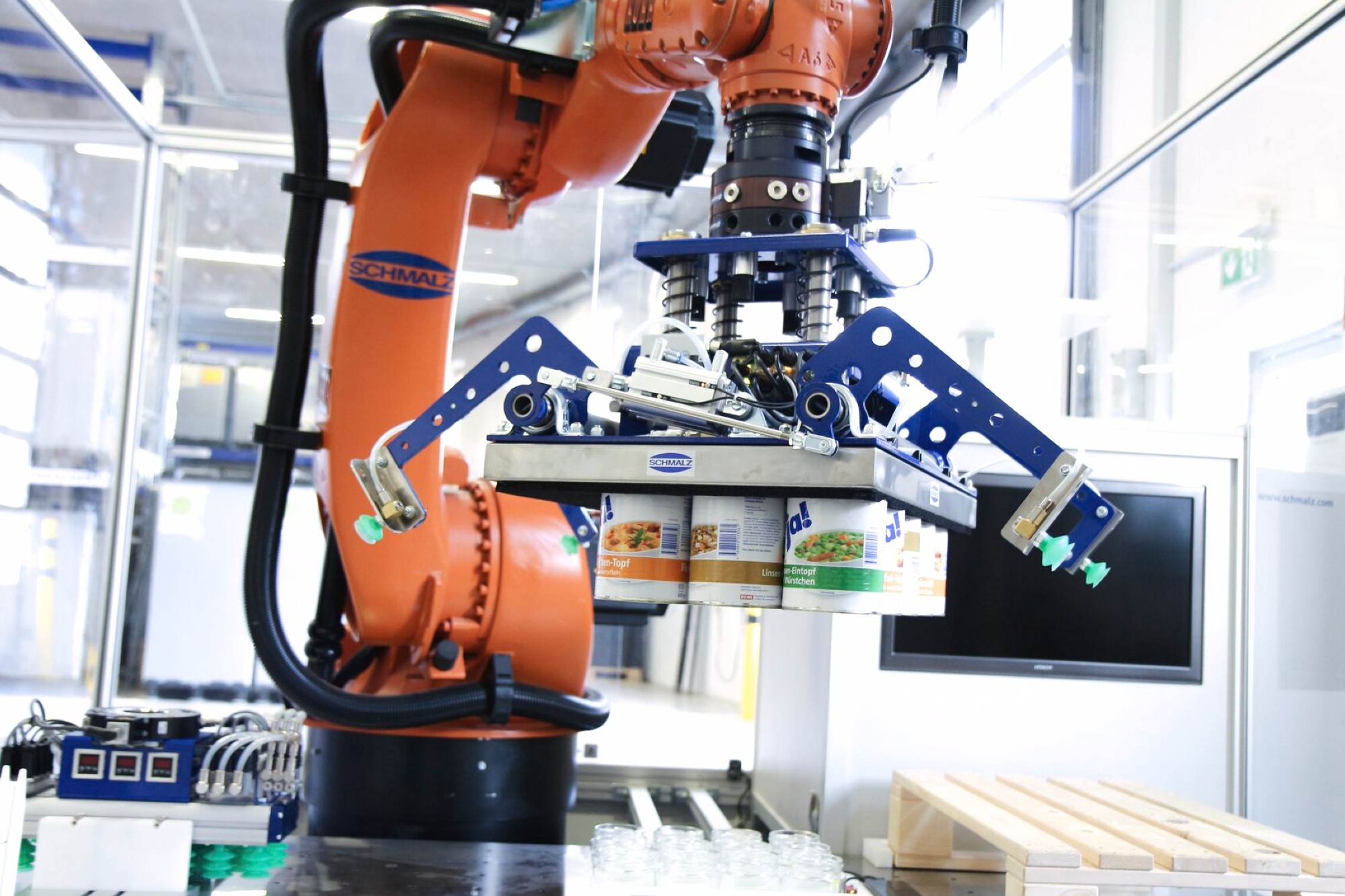

Several industrial automation technologies help increase manufacturing, reduce costs, and enhance production efficiency. Advanced robotics can accurately handle assembly and material, cutting labour expenses and boosting productivity. Machine vision is essential for quality control and precision, reducing reliance on manual inspection. Programmable Logic Controllers (PLCs) automate industrial processes, enhancing efficiency and minimising manual intervention. Industrial Internet of Things (IIoT) solutions collect and analyse data from diverse processes, providing insights to optimise production, lower expenses, and develop solutions for predictive maintenance, traceability, and energy efficiency.

How can the integration of advanced robotics into industrial automation strategies drive efficiency in manufacturing processes?

Integrating advanced robotics into industrial automation strategies can significantly enhance precision in assembly and boost productivity. Here are some strategies that can be employed.

Utilise advanced robots with superior perception and adaptability to allow for faster setup, commissioning, and reconfiguration, leading to more efficient operations. Cognitive robots can play a greater role here. They represent a new era of human & machine collaboration and help automate several internal & external customer experiences. They have built-in sensors & advanced AI functionality supported by deep-learning manufacturing environments. The AI functionality allows customers to program the robot quickly and efficiently using standard programming, hand motions & even speaking to robots. The AI also enables the robots to accommodate process changes without requiring re-programming. Customers who deal with flexible manufacturing or low-volume/high-mix manufacturing can benefit significantly from Cognitive Robots.

While deploying advanced robotics, the first and foremost focus should be automating manual tasks to drive higher productivity, such as assembling flexible parts. Collaborative and mobile robots are very adaptable, as they are very convenient for working seamlessly alongside humans, ensuring harmony and safety. Also, the ability of these robots to self-adjust to changing process parameters can improve resilience by eliminating micro stops.

Moreover, repetitive tasks and precision should be considered. Implement robotics capable of performing repetitive tasks with high precision, consistency, and speed, as this leads to increased productivity and reduced human errors.Combining advanced robotics with other technologies, process enhancements, and structural layout changes can help increase transition cost savings.

Deploy robots that execute tasks with precision and speed. It also streamlines production cycles and minimises errors, especially in sectors like automotive manufacturing, where intricate tasks such as welding and assembly are involved.

How do industrial automation solution providers systematically address manufacturing challenges to achieve scalability?

Industrial automation solution providers address manufacturing challenges and scale up automation processes through a multifaceted approach. It starts with a comprehensive assessment of the current manufacturing processes, infrastructure, workforce capabilities, etc., to identify areas for improvement and automation potential before moving to planning. It is followed by a thorough approach to providing customised solutions, innovative technology integration, collaborative vendor selection, paying close attention to proactive maintenance and downtime, and workforce training and reskilling to ensure continuous improvements for scalability.

How useful is ‘Make in India’ in scaling up manufacturing?

The Make in India initiative promotes manufacturing. It also contributes to economic growth, job creation, and technological advancement, positioning India as a significant player in the global manufacturing landscape. For industrial automation players like OMRON, it has opened new vistas and given us new opportunities to enhance our contribution to the Indian manufacturing sector and help manufacturers make “world-class” in India.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.