Schaltbau invests in ATEX-compliant automation to boost productivity

By Staff Report June 3, 2025 12:18 pm IST

Schaltbau GmbH continues to adopt advanced manufacturing technologies. The latest step includes integrating automated systems to streamline component processing and reduce manual intervention at the German facility.

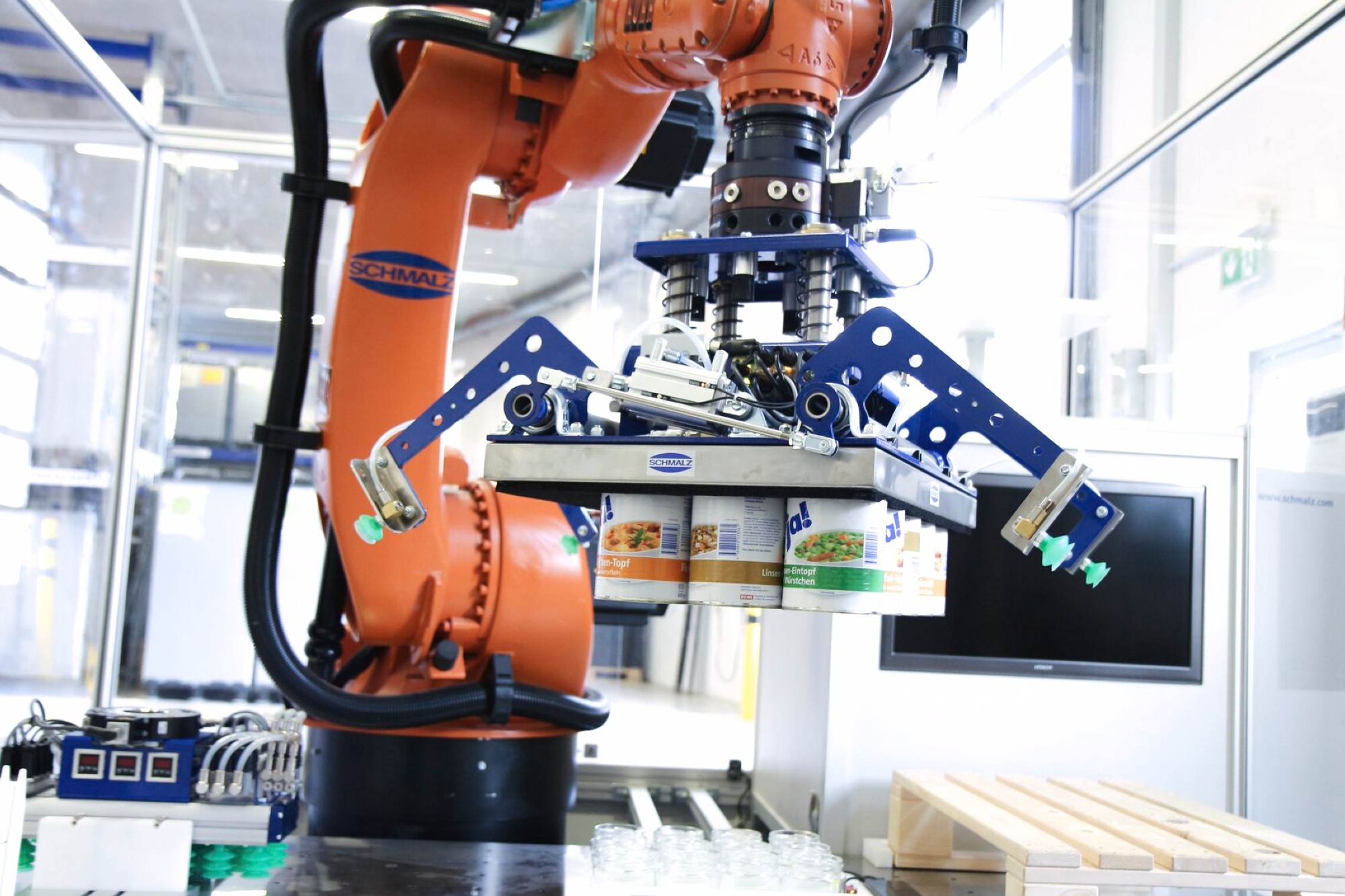

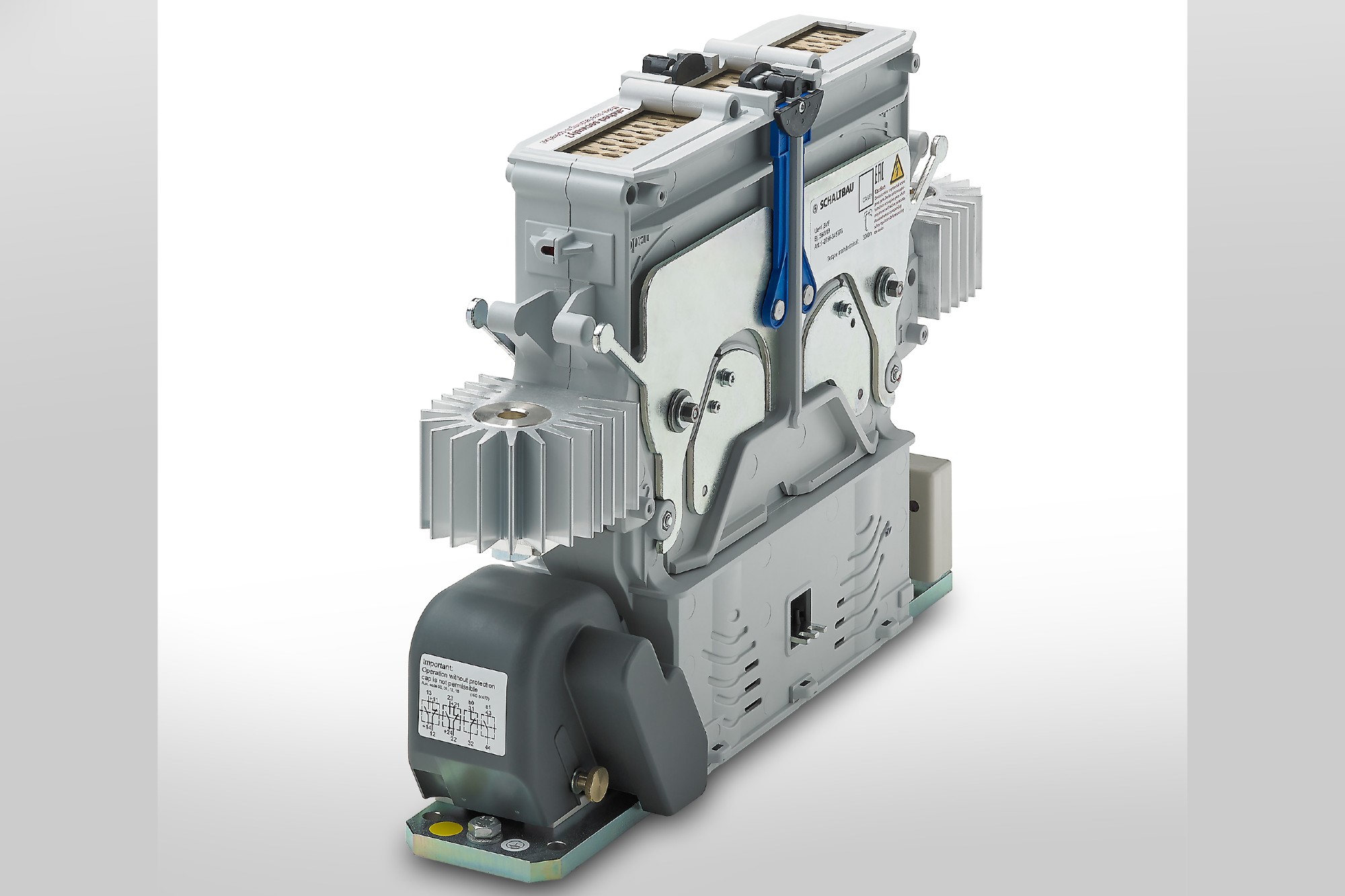

To gain a competitive edge through cost-efficient production, a leading manufacturer of electromechanical components for safe switching operations and direct current protection automated the de-flashing of plastic housings at the facility in Germany. The company selected the Rösler wire mesh belt blast machine, model RSAB 370-T1+1, which meets ATEX regulations. This move resulted in nearly a 50 percent reduction in personnel costs.

Reducing Manufacturing Costs Through Automation

Schaltbau GmbH, a global supplier of direct current (DC) solutions, implemented an automated de-flashing process for plastic switch housings at a production site in Aldersbach, Bavaria, Germany. The company invested in a Rösler blast machine with a wire mesh belt, model RSAB 370-T1+1, which meets ATEX compliance requirements. This automation measure reduced personnel needs by approximately 50 percent. Schaltbau GmbH, headquartered in Munich, operates across multiple divisions and provides electrification products and solutions for several industries.

The product portfolio includes contactors, plug connections, switches, and safety components. Under the Eddicy trademark, the company supplies DC switching and protection solutions for sectors such as energy and electric vehicles. Production facilities are located in Germany, Europe, the United States, and Asia.

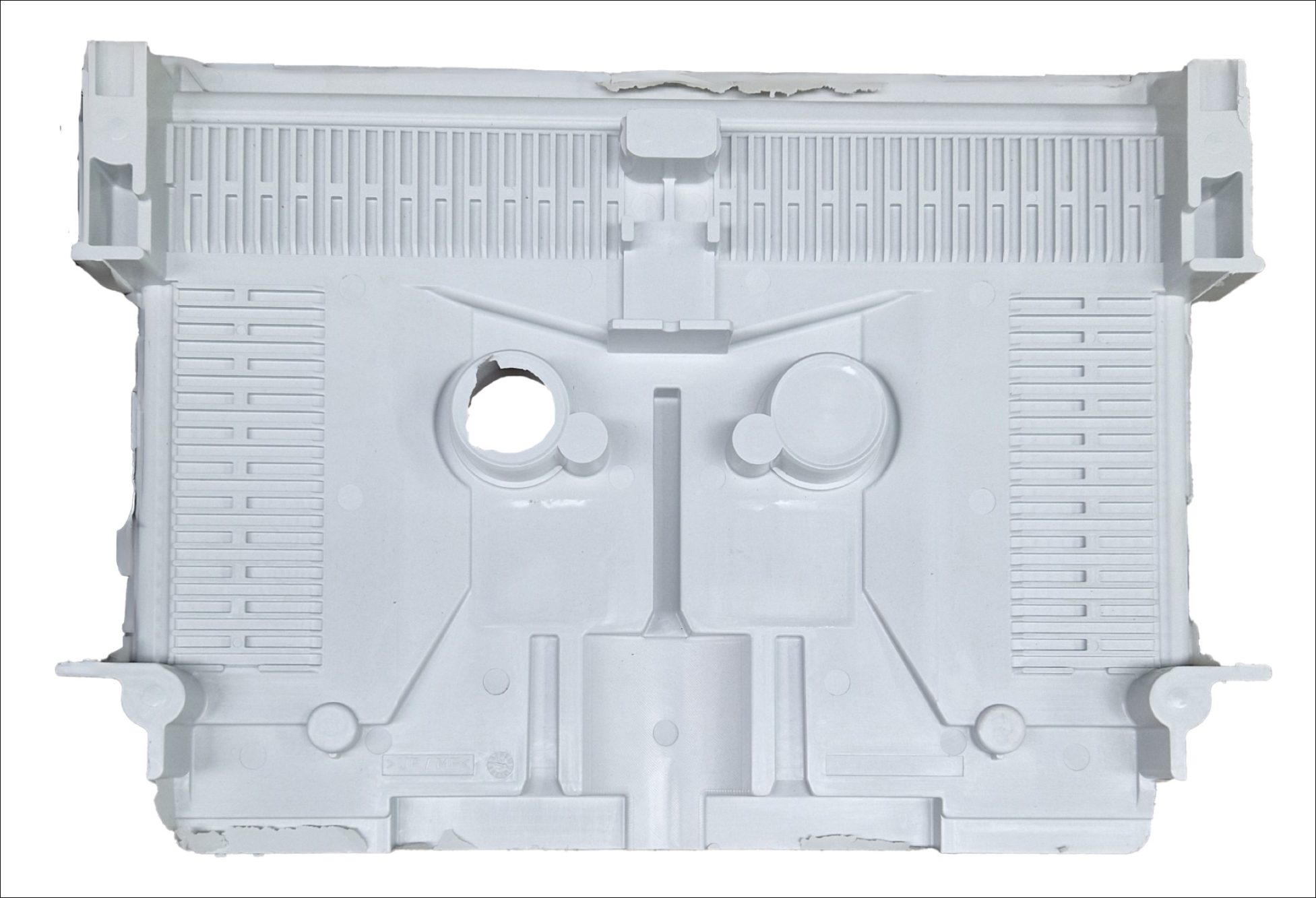

As part of a lean manufacturing project, the company evaluated the production of moulded housing components made from melamine/polyester materials. Material overflow during pressing produces unwanted flashes, removed to ensure proper assembly and functionality. Previously, this de-flashing step was performed manually, with one worker stationed at each press.

Schaltbau GmbH explored automation as a cost-saving measure and invited two existing equipment suppliers to propose solutions. Rösler, a long-standing partner in mass finishing technology, presented a solution that met the requirement for a gentle de-flashing process. The selected wire mesh belt blast machine allows for continuous, controlled de-flashing without causing component damage or blast media residue.

Effective De-Flashing with Fewer Personnel

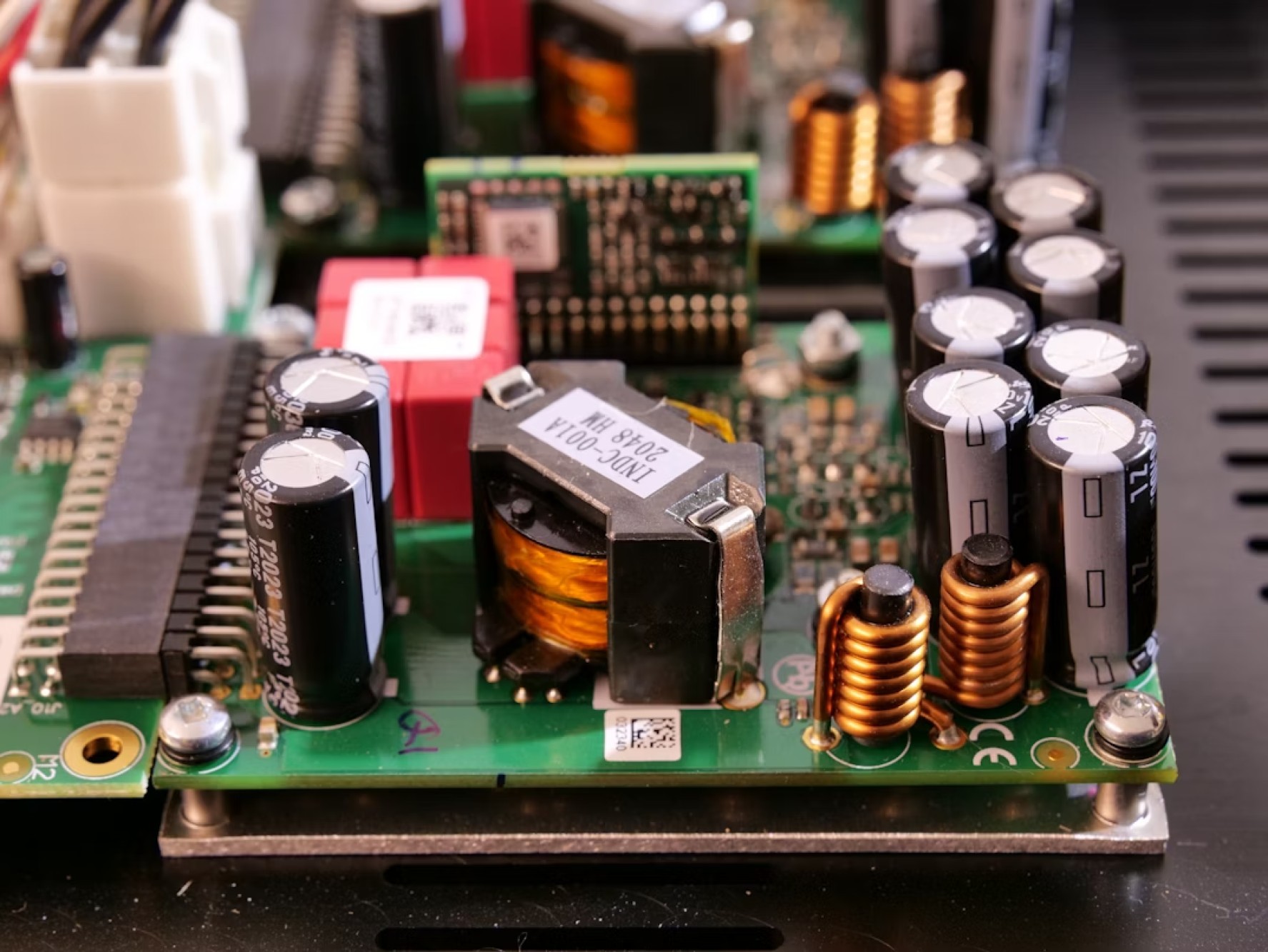

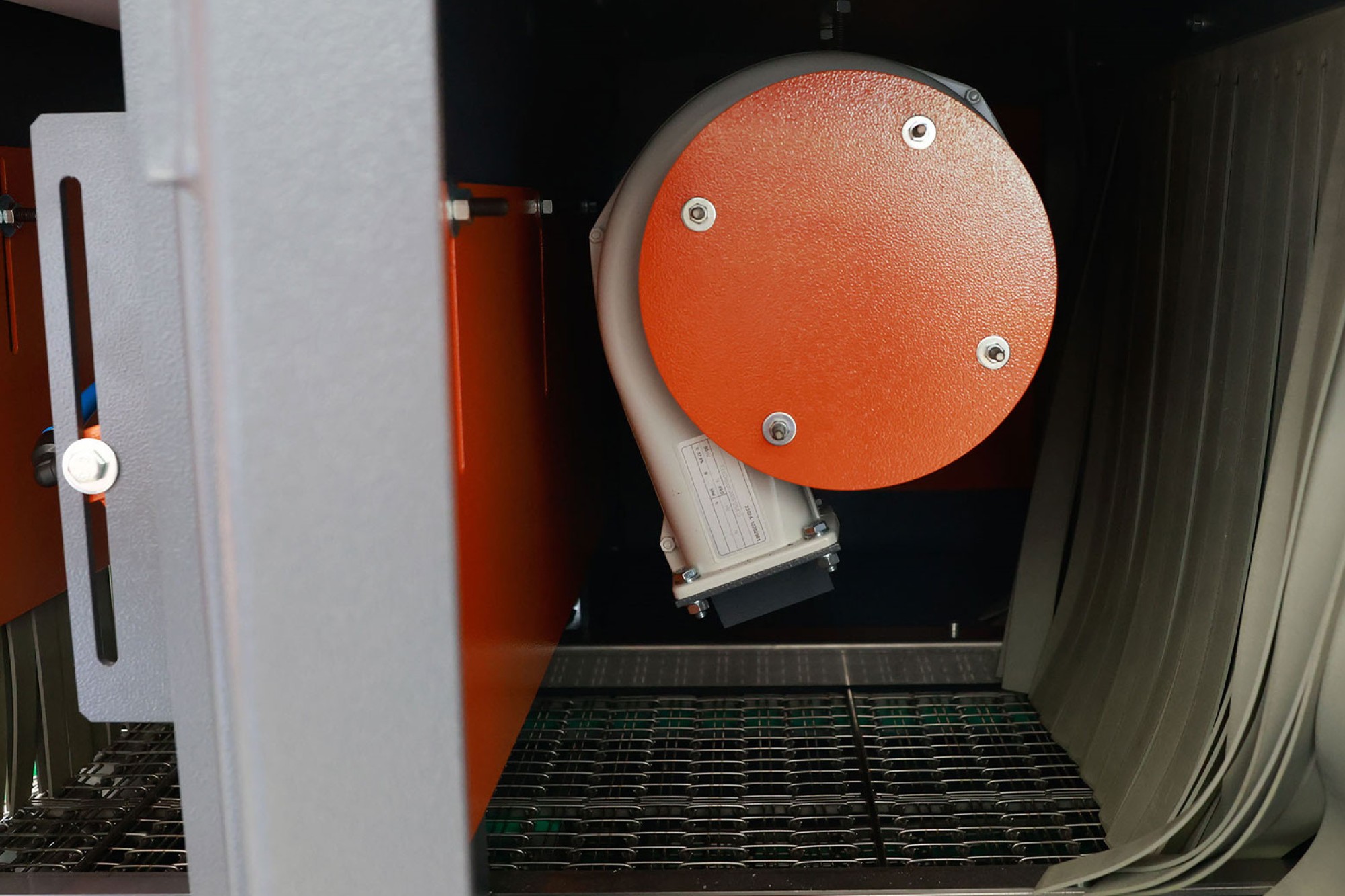

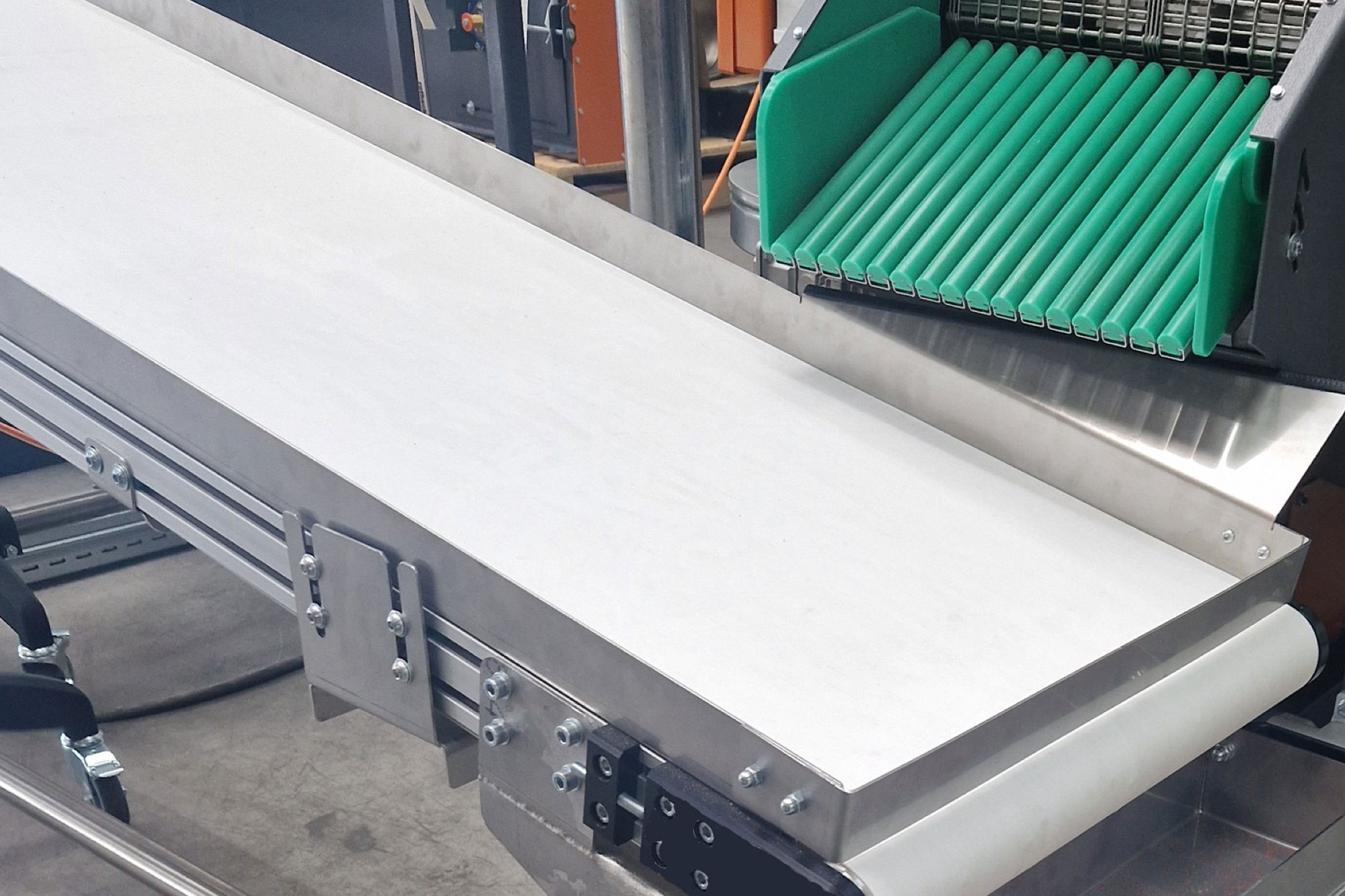

The RSAB 370-T1+1 model includes two W32 turbines—one above and one below the wire mesh belt—to direct polyamide pellet blast media onto components from all sides. Components are manually placed onto the 370 mm wide belt. The machine’s program-controlled transport speed is matched to component size and flash severity. Dust removal and a two-stage blow-off system ensure that clean components are produced at the output. Finished parts are transferred via an L-shaped conveyor to the loading area for manual removal. The machine is housed in a noise-absorbing cabin, and the belt length is extended to compensate for a shortened loading zone.

Safe Processing and Operation in Compliance with ATEX Regulations

The RSAB 370-T1+1 includes a blast media cleaning system with a vibratory screen, air-wash separator, and automatic media replenishment. An integrated anti-static system with compound dosing prevents blast media from adhering to components. The machine features a dust collection system in compliance with ATEX safety standards.

According to Armin Voggenreiter, Director of Operations at the Aldersbach site, this investment led to a personnel cost reduction of around 40 percent.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.