The Digital Enterprise merges the physical and digital realms

By OEM Update Editorial June 9, 2023 2:32 pm IST

According to Suprakash Chaudhuri, Head of Digital Industries at Siemens Limited, India, Industrial 5G is the solution to the requirement for comprehensive wireless networking in production, maintenance, and logistics. Its implementation promises substantial enhancements in efficiency and increased flexibility in industrial value creation.

What is your outlook for Industry 4.0?

The industrial world is subjected to rapidly changing challenges. The available resources are finite, and we must do more with less. Collecting, understanding and using the massive amount of data created in the Industrial Internet of Things (IIoT) is essential. The Digital Enterprise is doing this by combining the real and the digital worlds.

The industrial sector is constantly faced with evolving challenges, with limited resources requiring us to maximise productivity, implying we all need to do more with less. To address this, it is crucial to effectively gather, comprehend, and utilise the vast volume of data generated in the Industrial Internet of Things (IIoT). The Digital Enterprise accomplishes precisely this by merging the physical and digital realms.

As a result, the infinite amount of data allows us to use our finite resources efficiently, making the industry more sustainable. Digitalisation and automation are the game changers to meet these challenges on the way to Industry 4.0.

Consequently, harnessing the infinite amount of data enables us to optimise utilising our limited resources, promoting sustainability within the industry. Digitalisation and automation emerge as the pivotal factors that are game changers in addressing these challenges as we progress towards Industry 4.0. Siemens solutions for the Digital Enterprise enable the customers to invest in future-proof solutions for the gradual implementation of Industry 4.0

How do you evaluate 5G routers application for the manufacturing industry?

Deploying industrial 5G is a milestone on the path to Industry 4.0. It is a catalyst for accelerating the digital transformation of industrial enterprises. Thanks to reliable, powerful broadband transmission with massive machine connectivity and ultra-low latencies, Industrial 5G is the response to a need for end-to-end wireless networking of production, maintenance, and logistics, ensuring a significant improvement in efficiency and greater flexibility in industrial added value.

With the launch of our SCALANCE MUM853-1 and SCALANCE MUM856-1 routers, our customers can achieve extremely high data rates (enhanced mobile broadband, eMBB) that support easy and secure remote access use cases, greater reliability, lower latency, and lower power consumption delivering streamlined 5G connectivity.

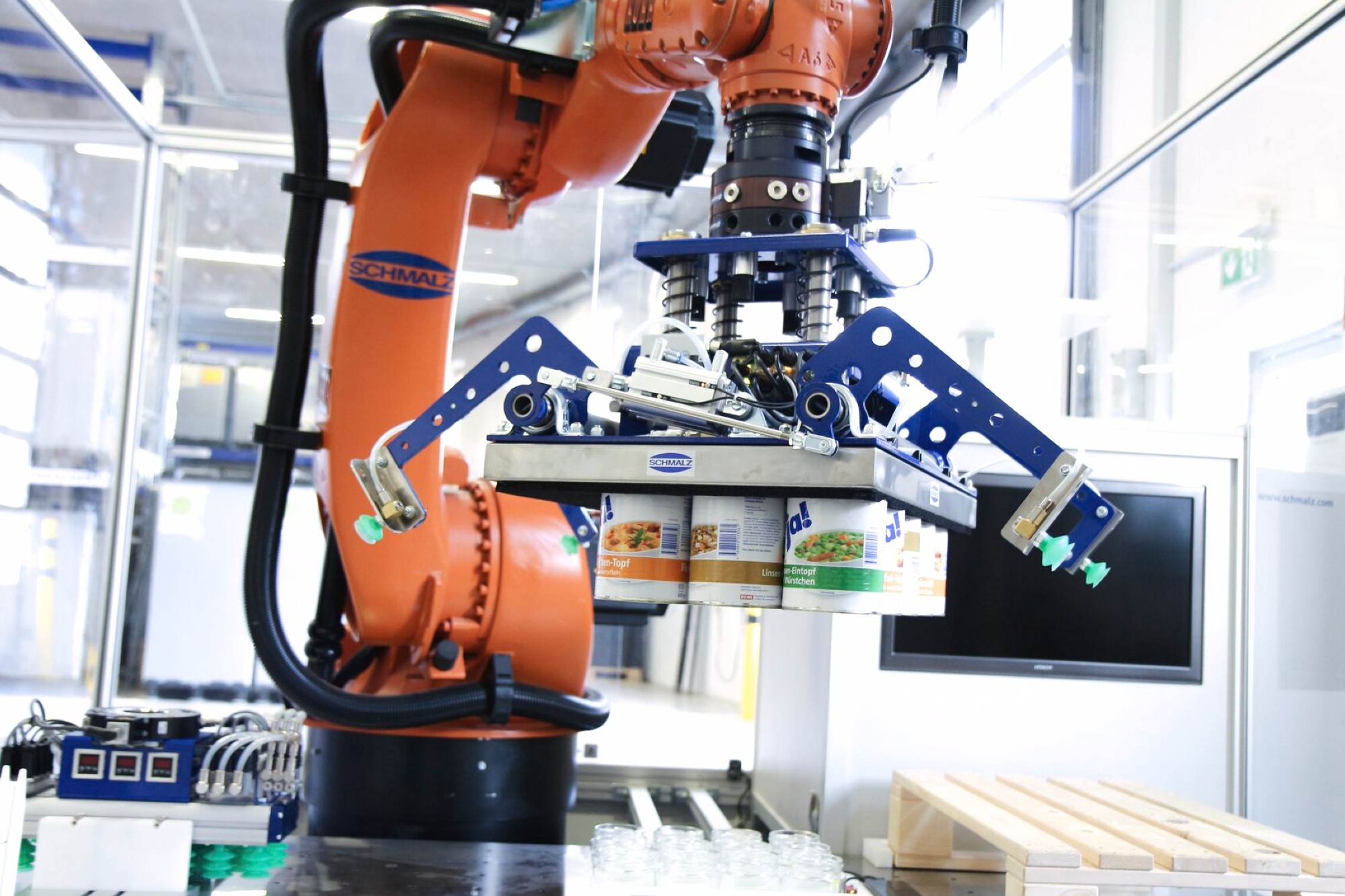

In what ways Industrial 5G will deliver benefits to a wide range of customer segments?The applications on industrial 5G offer long-term benefits to a wide range of customer segments that depend on a strong and reliable communication backbone, such as intralogistics, autonomous machines, industrial edge, remote diagnostics, augmented reality, assisted work, wireless backhaul, edge computing and mobile equipment.

Whether for discrete manufacturing, process industries, or utilities – Industrial 5G wireless communication technology and private 5G networks will play an important role in the factory of tomorrow.

Please talk about the end-to-end integration of automation systems to accelerate digital transformation.

Industrial companies must be more efficient and flexible to thrive in and sustain today’s fierce competition. Highly digitalised companies can quickly cope with the sudden changes arising in the market. The end-to-end integration of automation brings together processes that were previously separate. It breaks down traditional silos and helps bridge the gaps between software and hardware, IT and OT, shop floor and top floor and end-to-end integration of systems. Integrated cutting-edge technologies in the Digital Enterprise portfolio enable smart usage of data. This paves the way for the next level of the digital transformation of the industry with the convergence of information technology and operational technology.

The industrial 5G user equipment is also one of the critical components for the manufacturing industry in its digital transformation, enabling faster, reliable, and secure communication within the IT/OT environment, accelerating an enterprise’s digital transformation.

What specific features of 5G routers will enhance transmission and communications in future?

Enhanced Mobile Broadband Connectivity (eMBB), Massive Machine Type Communication (MMTC) and Ultra-low latency & Reliable connection (URLLC) are the three important factors for realising 5G applications. With the launch of our SCALANCE MUM853-1 and SCALANCE MUM856-1 routers, our customers can achieve extremely high data rates (enhanced mobile broadband, eMBB) that support easy and secure remote access use cases, greater reliability, lower latency, and lower power consumption delivering streamlined 5G connectivity. The devices offer high bandwidths of up to 1000 Mbps for the downlink and up to 500 Mbps for the uplink, providing high data rates for data-intensive applications such as the remote implementation of firmware updates. Owing to the IPv6 support, the devices can also be implemented in modern communication networks.

Various security functions are included to monitor data traffic and protect against unauthorised access: for example, an integrated firewall, authentication of communication devices, and encryption of data transmission via VPN. The devices have been developed for applications in demanding industrial environments and can be used in public and private 5G campus networks. The compact SCALANCE MUM853-1 router is designed for cabinet use, while the rugged IP65 housing of the SCALANCE MUM856-1 means it can be directly mounted on stationary or mobile components. The built-in IPv6 support and the fallback to lower cellular standards (4G, 3G) whenever 5G connectivity is unavailable make SCALANCE MUM853-1 and MUM856-1 the required flexibility in the OT environment. Because they use VXLAN, the routers enable PROFINET communication via private 5G networks (Release 15), meaning they can leverage new potential for industrial enterprises.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.