The IIoT is Here

By OEM Update Editorial June 12, 2018 11:00 am IST

Manufacturing is the space which has seen huge progress in the adoption of IIoT and is the biggest market which has made most investments and consequently witnessed maximum implementations around IIoT till date.

Today, term Internet of Things (IoT) no more needs any introduction as it’s been a buzzword since a couple of years now and same is the case with Industrial Internet of Things (IIoT) which is a subset of IoT. IIoT is nothing but the convergence of different old and new technologies like Machine Learning, Artificial Intelligence, Cloud Integration, Connected Devices, Big Data, Sensor Data, automation, robotics etc which are already in use in industries for quite a few years now. In simple words, IIoT is IoT capabilities implemented for any industrial use case. Further, manufacturing is the space which has seen huge progress in the adoption of IIoT and is the biggest market which has made most investments and consequently witnessed maximum implementations around IIoT till date.

IIoT in manufacturing industry

There are many reasons why manufacturing industry is most impacted by changes brought in by IIoT. It’s very easy to understand that no other industry has such a huge potential for actual IIoT deployments which can offer rapid return and enable stakeholders to experience growth and development on numerous fronts like improved productivity, higher levels of automation, better customer-focus, competitive edge and endless advantages of using data across the value chain which helps in penetrating into new revenue streams. As per IDC report, published in 2017, a total of around $178 billion was spent on IIoT and related projects in the manufacturing industry alone which is 2X from the IoT spend in transportation segment which is the second largest vertical for IIoT.

The developments made and money spent in this area is usually perceived in two ways i.e. inward facing and outward facing. Projects revolving around continuous process optimisation, real-time tracking and monitoring, and predictive maintenance are inward interfacing. On the other side, outward facing approach involves investments which are made to identify customer requirement and behaviour by collecting market data so as to understand trends and generate some insights on the product or service.

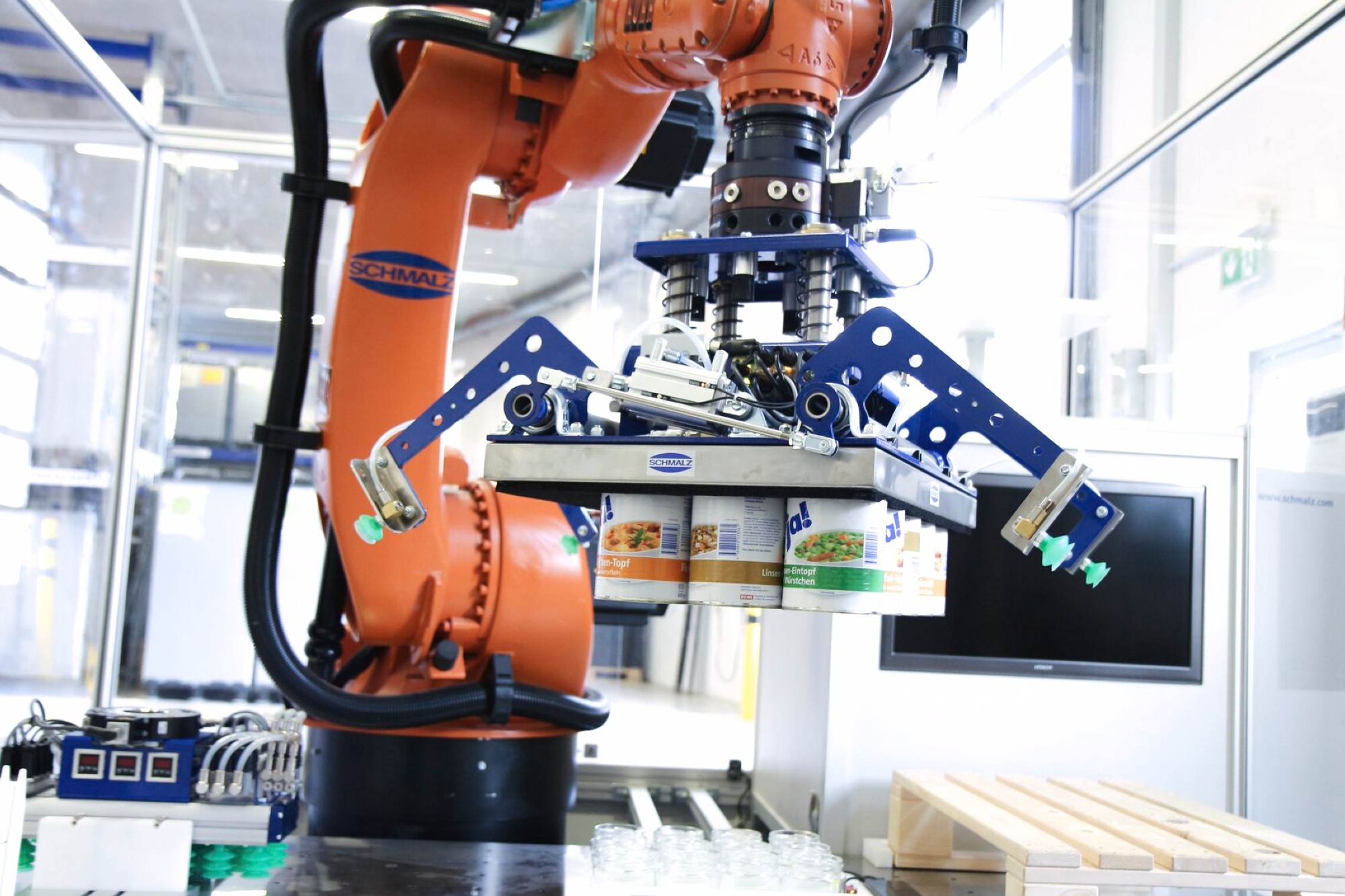

IIoT empowers manufacturing

There are three important key use cases of IIoT in the manufacturing industry. First one is around improvements in manufacturing operations or processes which involves performance optimisation, operational visibility, process monitoring, planning and human-machine interfacing. Second is production asset maintenance and management which majorly includes equipment monitoring, output quality tracking and most importantly forecasting potential breakdowns or bottlenecks. Third is customer servicing, where manufacturers are supposed to provide product and business-related services. IIoT empowers manufacturers as well as users with the tools to plan, schedule and pre-empt any service requirement.

Challenges

Expertise of Hi-Tech RoboticsHi-Tech Robotics is developing systems which can harness the true potential of IIoT and propel its partners towards the growth trajectory they are planning to have. With a major focus to move towards the convergence of autonomy, mobility, connectivity and analytics the core of all the products is Artificial Intelligence (AI) with the key objective of building self-learning capabilities in machines so as to develop systems which have a human-like thought process. Novus Analytics is an IIoT-based analytics tool which can be used to integrate all autonomous mobile robots developed by Hi-Tech Robotics alongwith other third-party software or hardware items running at the customer site for different applications. With the use of machine learning and other data analytics techniques, Novus Analytics logs, consolidates and presents data to the user in such a way so that one can analyse it to improve processes and increase productivity. On one side, execution teams can perform RCA (Root Cause Analysis) on data, pre-empt system failures and take corrective measures and on other side, decision makers can plan with full knowledge and understanding of the ground-zero situation.

Conclusion

There remains no doubt about the fact that IIoT is one of the primary trends affecting manufacturing businesses today and it will have an even bigger impact in near future. Manufacturers need to work hard towards modernisation of their systems and equipment, so as to embrace the benefits of IIoT and see improvements in productivity, quality, maintenance, safety, decision making and most importantly, continuous growth.

Authored by:

Kunal Pruthi

Consultant- Solutions & Business Development

The Hi-Tech Robotic Systemz Ltd

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.