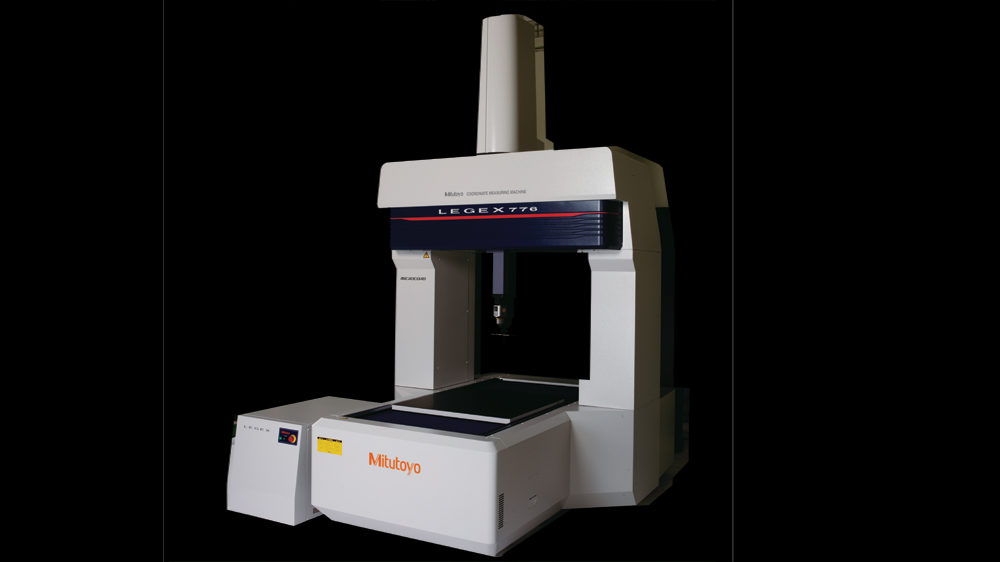

LEGEX: Ultra high accuracy 3D CNC coordinate measuring machine

By OEM Update Editorial December 11, 2017 11:01 am IST

LEGEX is the culmination of 80 years of Mitutoyo technology. Recognised as the world’s ultimate high accuracy 3D CNC CMM, LEGEX offers an accuracy of (E0, MPE = 0.28 + L/1000) µm.

Mitutoyo Research & Development team is constantly engaged into development of new technologies. High-precision machining, drive mechanism and encoder or sensor techniques play a very important role in making its CMMs very robust and long lasting. The highest accuracy in LEGEX series has been achieved because of Mitutoyo’s focus on superior design, materials and manufacturing techniques followed at state-of-the-art facility in Japan, the company said.

For an unmatched performance, LEGEX uses a fixed bridge structure with integrated Y axis guide rails, central drive and precision air bearings running on rigid guide ways ensuring superior stability of motion and ultra-high measuring accuracy. LEGEX is equipped with ‘air-damped spring isolators’ having auto-levelling feature to completely isolate the measurement from any possible floor vibrations. A newly developed ultra-high accuracy crystallised-glass scale with an ultra-low expansion coefficient of 0.01×10-6/K is used on each axis. This ultra- high accuracy 3D CNC CMM has been made possible through rigorous analysis of all possible error-producing factors and elimination or minimisation of their effects.

A variety of optional probe systems are available, including touch-trigger probe; scanning probe, laser probe, surface roughness probe, vision and other special probes like UMAP and MPP. Mitutoyo’s MPP-310Q is ideal for low measuring force and ultra-high accuracy, while the MPP10 is the only probe in the world dedicated for effective thread-depth measurement.

Machines in this series are suitable for complex, small- to medium-sized workpieces such as gears, bearings, lenses, dies and scroll rotors and master gauges which must be inspected to exceptionally high dimensional accuracy.

This superior structure is powered by the industry leading MCOSMOS family of software by Mitutoyo featuring simple geometric measurement, profile scanning, digitising, online/offline part program creation as well as additional applications such as gears and air-foil inspection.Contact

Mitutoyo South Asia Pvt Ltd

C-122, Okhla Industrial Area, Phase-I, New Delhi-110 020

Tele: +91-11-26372090, 40578485

Email: delhi@mitutoyoindia.com

www.mitutoyoindia.com

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.