Shot blasting over conventional sand blasting, for subsequent finishing

By OEM Update Editorial October 17, 2019 12:45 pm IST

Steel shot blasting is a process where abrasive particles are pneumatically or centrifugally accelerated and forcefully directed against a surface. These high speed abrasive particles remove contaminants from the material’s surface and condition the surface for subsequent finishing.

Shot blasting is a fabulous process to give the desired finish to critical components than using different technology. It still remains one of the less known processes but an important one. It is normally done on concrete or metal surfaces. While similar to a sandblasting process, shot blasting is very much different in the way it is executed and exhibiting effectiveness. Almost every industry that uses metal including aerospace, automotive, construction, foundry, ship-building, rail, and many others makes use of shot blasting.

Shot blasting over conventional sand blasting

Steel beads are “shot” inside a machine onto the component to clean it in an industrial manner. To begin, you load the machine with the beads or shot pellets. The beads “blast” off any stains embedded on the components that can’t be removed through normal cleaning methods.

Typical shot blasting application includes:

- Roughening surfaces in preparation for thermal spraying, painting, bonding or other coating operations

- Removing rust, scale, sand, or paint

- Providing a matte surface finish

- Removing flash from moulded components

- Cosmetic surface enhancement or etching

Quality Spares Centre is one of the few names to offer a vast and qualitative range of industrial steel abrasive products. Committed to follow fair business practices, they have earned the desired goodwill in the market.

Achievement

Being unaware here-in-before, the auto components industries have been using the sand blasting medium for surface treatment of components such as nuts, bolts, screws, clutch plates etc. etc. By evolving a new technique, the company has accomplished this function by using shot blasting process in place of sand blasting i.e. completely automatic component feeding in place of the conventional manual feeding.

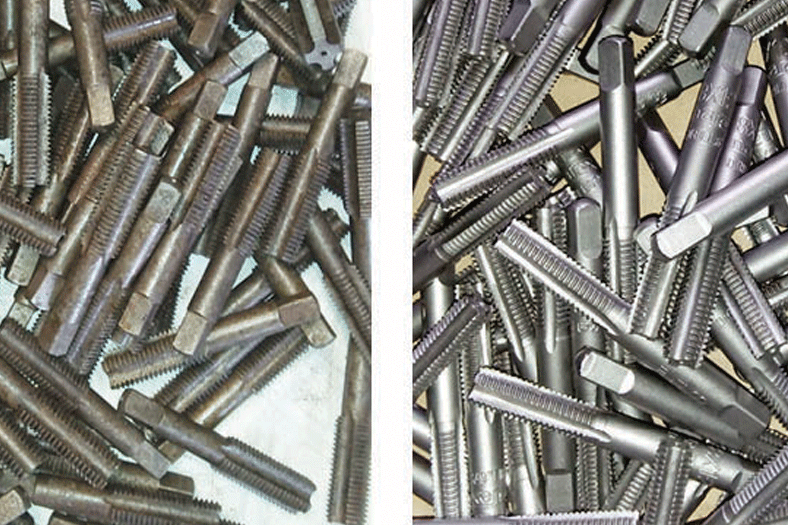

This photo illustrates how effective shot blasting is. You can see on the left side of the image, the components are black, scratched and mucky while the right side looks almost as if they are brand new components.

Before shot blasting and after shot blasting

Shot blasting of these critical components have yielded 100 per cent results with zero- defect and to the entire satisfaction of customers.

For more details contact:

Rajan Sikka

Proprietor

Quality Spares Centre

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.