ABB IRB 1010 robot to meet the growing demand for wearable smart devices

By OEM Update Editorial November 8, 2022 2:35 pm IST

It offers new and more flexible possibilities for faster and higher quality products and meets manufacturers’ demands, enabling companies to maximise their outputs.

Cobots, or collaborative robots, are robots that work alongside humans taking operations to the next level. They work hand in hand with humans balancing the imperative for safety with the need for flexibility and productivity. As a pioneer in robotics and automation, ABB offers the broadest portfolio on the market. Our family of collaborative robots – designed with best-in-class safety – facilitate close collaboration with humans.

Cobots are designed for low payload applications such as handling small parts and inspection tasks. But there is so much more: AI integration and software can transform any connected industrial robot with higher payloads and faster speeds into a collaborative one. From testing samples in labs to making computer chips, collaborative robots (cobots) are working together with humans to transform our lives. Cobots are taking on repetitive and mundane tasks and helping create flexibility and scalability for small and medium-sized enterprises to grow. ABB has recently launched its smallest-ever industrial robot for wearable smart devices.

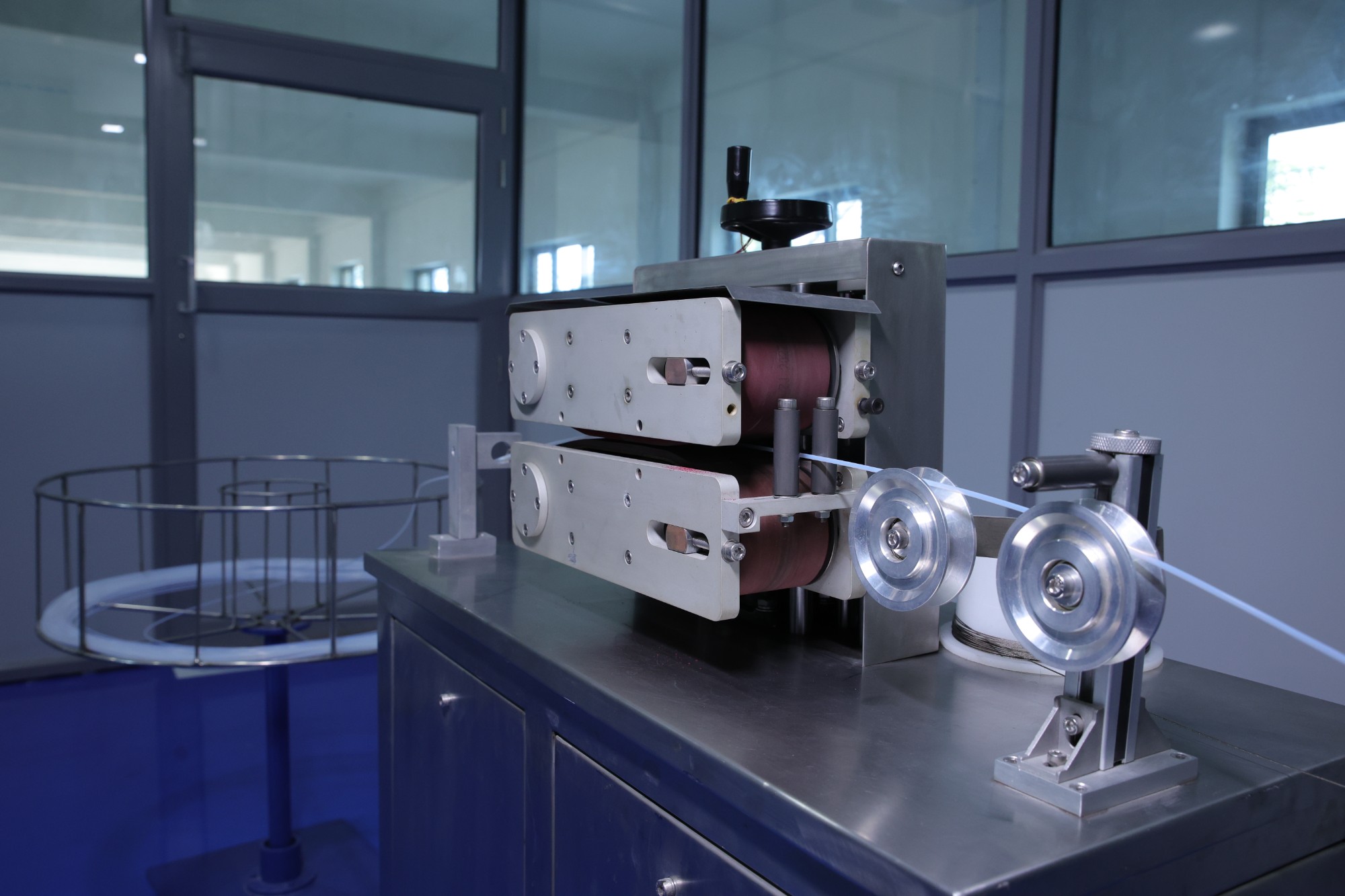

The IRB 1010, as it is called – offers new and more flexible possibilities for faster and higher quality production. Its compact size, class-leading payload, and unrivalled accuracy allow electronics manufacturers to increase their output of devices, including smart watches, earphones, sensors, and health trackers, through automation.

The market for wearable smart devices has been accelerating rapidly in recent times. The projections for these devices estimate a double-digit growth between 2022 and 2028. This has led to companies demanding compact robotic solutions suited to narrow production spaces within the electronics manufacturing lines. They also require products that can accurately handle the small components which are used in wearable devices. The new IR 1010 was designed to meet this growing consumer and manufacturer demand.

The IR 1010 is the most accurate robot currently on the market for handling 1.5kg payloads. ABB’s IRB 1010 meets manufacturers’ demands, enabling companies to maximise their output and productivity while maintaining the highest levels of product quality.

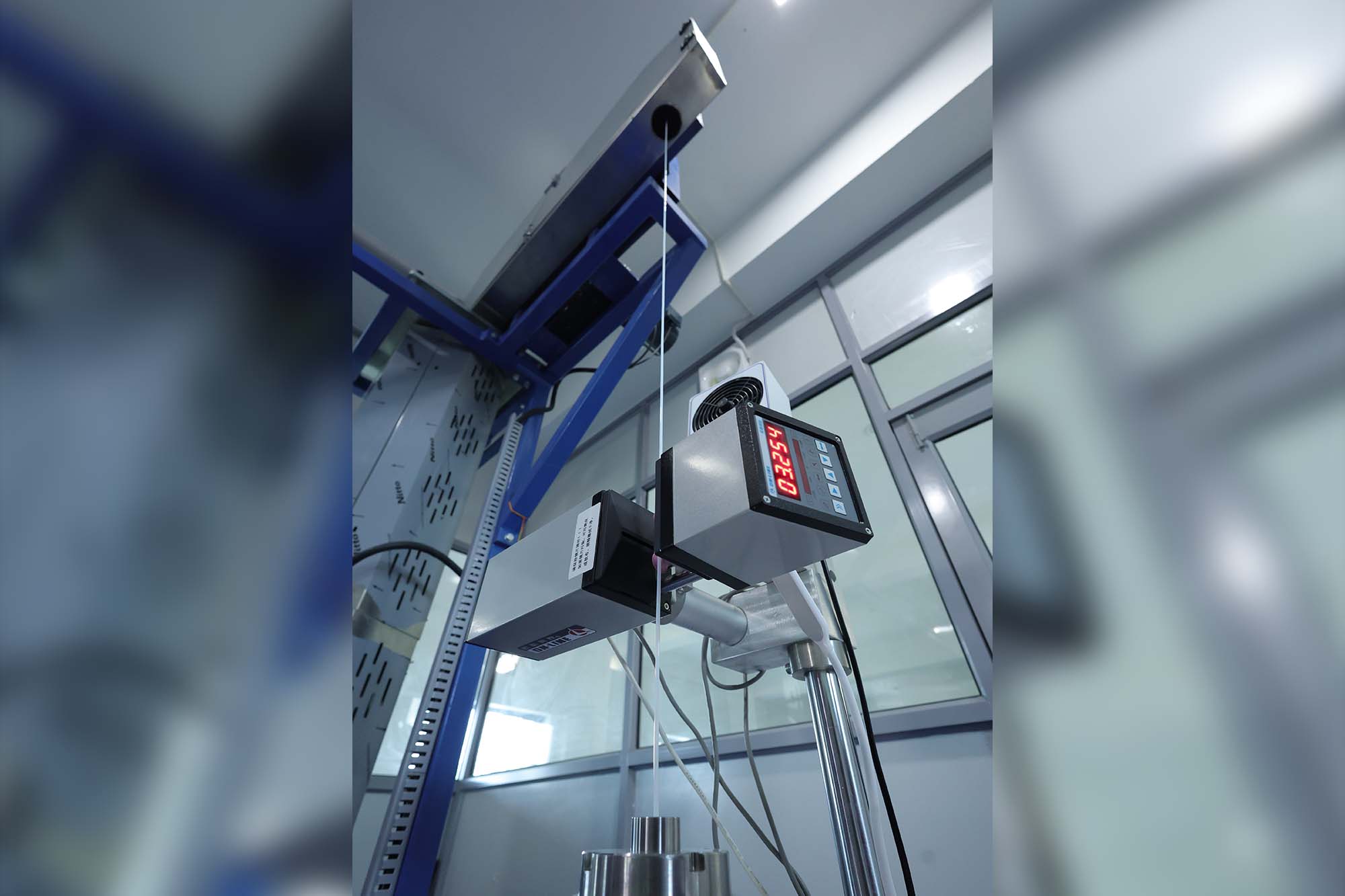

ABB’s IRB 1010 suits the narrow spaces and special-purpose machines typical of electronics production environments. With a reach of 370mm and a footprint of 135mm by 250mm, the IRB 1010 is 30 percent smaller than the company’s previous miniature robot, the IRB 120. These compact dimensions increase the number of cells fitted into production spaces, enabling manufacturers to boost output through higher-density factory layouts.

The product further enhances productivity with the inclusion of six braking systems. This allows the robot arm to remain in its position even when stopped by eliminating the time needed for the robot to recover its position after a stop or pause. This feature ensures production can be resumed more quickly, enabling the IRB 1010 to do more in less time than other robots in its class.

Key to the IRB 1010’s high accuracy is ABB’s OmniCore E10 controller. This controller offers class-leading position and path repeatability of 0.01mm. The controller’s slimline design is well suited to small-part assembly applications where production cell sizes must be minimised. It also offers the flexibility to meet changing requirements with its built-in digital connectivity and over 1000 additional functions, which enable easy scalability.

The new OmniCore E10 controller consumes up to 20 percent less energy than ABB’s previous IRC5C controllers. Therefore, the OmniCore E10 also enables manufacturers to reduce energy costs and improve energy efficiency.Another benefit of IRB 1010 is its simple programming. This allows even novice programmers to gain a handle on the device with ease.

This is due to ABB’s Robot Control Mate, available as an add-on to ABB’s RobotStudio programming software. The Robot Control Mate enables users to move, teach and calibrate the IRB 1010 from their computer or mobile tablets without programming skills.This simple programming and the small size of the IRB 1010 also opens new possibilities for educational applications. The IRB 1010’s compact design makes it suitable for installation on classroom desktops. Its ease of use enables teachers and students to master the skills needed for programming and operation.

The addition of the IRB 1010 complements ABB’s comprehensive range of articulated industrial robots, which includes a full range of small, medium, and large options, including a growing family of collaborative robots that can be safely deployed alongside workers. ABB states that collaborative robots take operations to the next level. They believe that cobots work hand in hand with humans to balance the imperative for safety with the need for flexibility and productivity.

The popularity of cobots has increased dramatically in the past few years due to their numerous benefits. Cobots improve worker safety and satisfaction by taking over dangerous tasks within production. They allow productions to be much faster and more efficient without compromising quality. They also help maintain consistency amongst the products while enhancing productivity. By meeting this ever-increasing demand with top-of-the-line offerings, ABB has become one of the leaders in cobot development.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.