Enhance dies and moulds durability with duplex surface engineering solutions

By Staff Report September 17, 2024 11:38 am IST

The die and mould industry is the backbone of manufacturing, shaping the intricate components that power the world. Enter Duplex Surface Engineering is a two-step process combining nitriding and PVD coating strengths to create a superior defence against wear, tear, and corrosion. This article explores how Duplex Surface Engineering empowers dies and moulds to achieve exceptional performance and reshape the future of manufacturing.

As industries like automotive and aerospace demand ever-higher precision and longevity, traditional surface treatments are reaching their limits. The die and mould support the creation of intricate and precise components essential for various industries, including automotive, aerospace, consumer goods, packaging, and healthcare. India’s die & mould sector is expected to grow substantially, and it is projected to surge by 10-15 percent in the coming years. This growth is fuelled by increasing localisation trends in the Indian automotive industry, aerospace, defence, consumer goods, EMS, packaging expansion, and the ever-increasing FDIs in various sectors. Surface finish in the die and mould industry is critical for achieving high-quality outputs.

Importance of surface engineering

Surface engineering is crucial in the dies and mould industry, as improper treatment can lead to significant challenges for customers across various sectors, including automotive, packaging, medical, and aerospace. When surface treatment is not executed correctly, it can result in issues such as increased wear and tear, reduced lifespan of the dies and moulds, and compromised product quality.

In the automotive industry, for example, inadequate surface treatment can cause premature mould failure in manufacturing car parts, leading to costly recalls and safety concerns. In the packaging industry, poor surface engineering can result in defects in packaging materials, affecting product integrity and shelf life.

The medical industry, which demands high precision and hygiene, may face contamination risks and reduced accuracy in medical devices if surface treatment is not up to standard. Similarly, in the aerospace sector, improper surface engineering can lead to structural weaknesses in critical components, posing serious safety risks.

Proper surface treatment in the dies and mould industry ensures product reliability and enhances functionality, performance, and longevity. Duplex Surface Engineering is a highly effective method for superior surface finish.

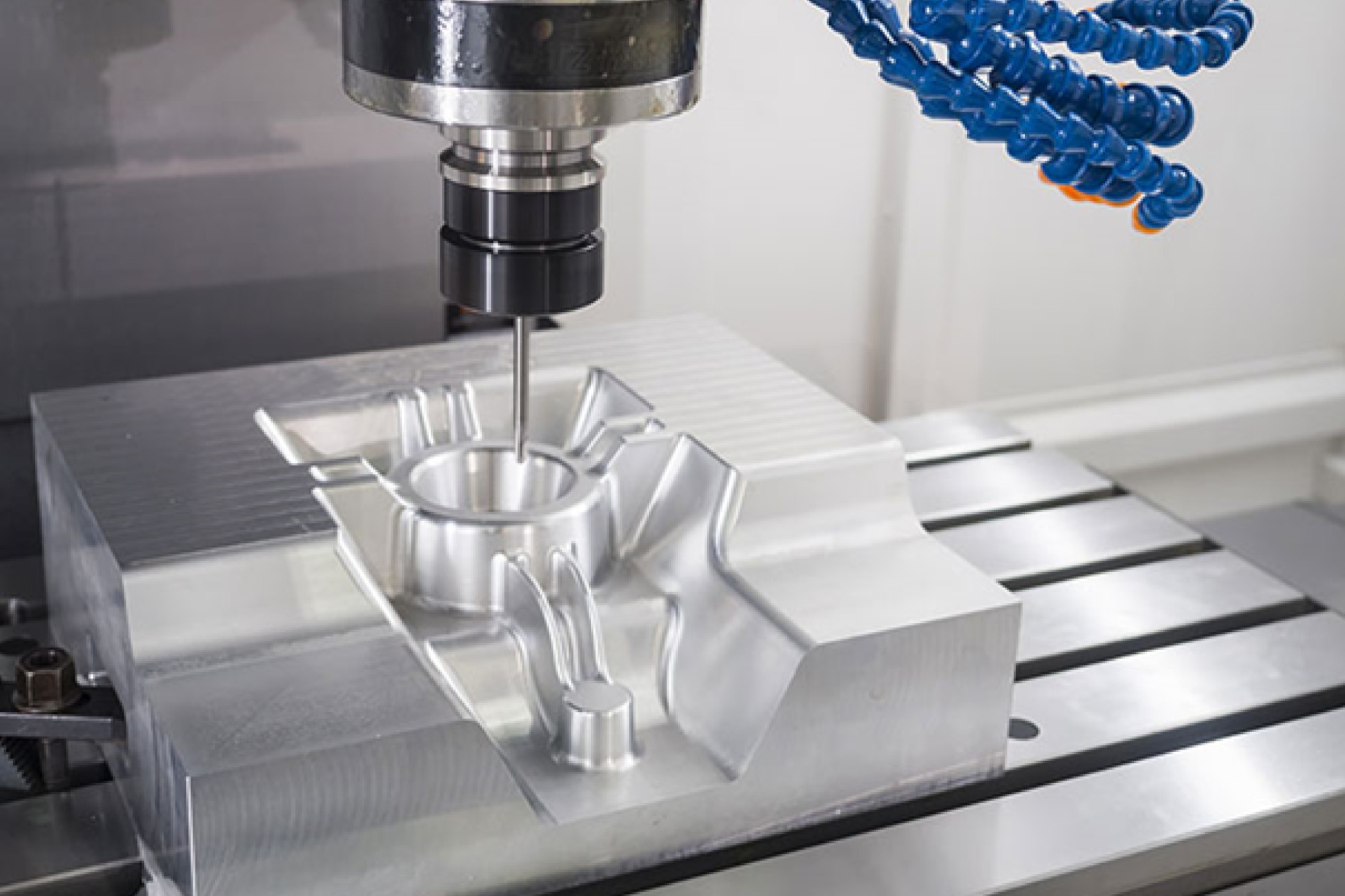

Duplex Surface EngineeringDuplex Surface Engineering is a two-step process that combines Nitriding and PVD coating to improve the surface properties of die and mould tools. Nitriding is a thermochemical process that introduces nascent nitrogen into the surface of the tool, creating a hard, wear-resistant layer. It is done at a temperature between 500- 550°C in a controlled gas atmosphere. PVD Coating is a vacuum deposition method for producing thin films and coatings.

Advantages and applications for Dies and Moulds

Combining Nitriding and PVD coating in Duplex Surface Engineering provides technical advantages such as enhanced wear resistance, increased surface hardness, improved corrosion resistance, reduced friction, greater fatigue strength, dimensional stability, and precision.

Duplex Surface Engineering is beneficial in industries where dies and moulds are subjected to extreme operating conditions, such as the automotive, aerospace, consumer electronics, medical, food and beverage, and packaging industries. Overall, Duplex Surface Engineering provides tools that deliver superior performance and longevity.

Duplex surface engineering enhances the performance of dies and moulds for the manufacturing industry. By combining nitriding processes with PVD coatings, this technique offers a robust solution to the common challenges of wear and corrosion. The result is a significant extension of the service life of tools, which is vital for the high demands of modern production environments.

voestalpine Group understands the critical role of highperformance dies and moulds in modern manufacturing. It offers a portfolio of innovative steel solutions designed for demanding applications. voestalpine High-Performance Metals India operates in-house heat treatment and surface treatment facilities, including nitriding and PVD coating capabilities. It partners with customers to develop and implement surface engineering solutions for their needs.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.