India is now self reliant on PTFE extruded liners for control cables

By Staff Report June 12, 2025 2:34 pm IST

Yash Dynamics Pvt Ltd, based in Dehradun, is India’s pioneering PTFE extruded tube manufacturer using advanced vertical paste extrusion technology. It delivers high-performance, ISO-compliant solutions for diverse industrial and medical applications.

Yash Dynamics Private Limited is an Indian-origin fluoropolymer processing company specializing in the manufacturing of superior quality PTFE (Polytetrafluoroethylene) tubes using advanced vertical paste extrusion technology. With a strong commitment to innovation and quality, the company is steadily establishing its presence in the Indian fluoropolymer industry, focusing specifically on PTFE extruded tubing.

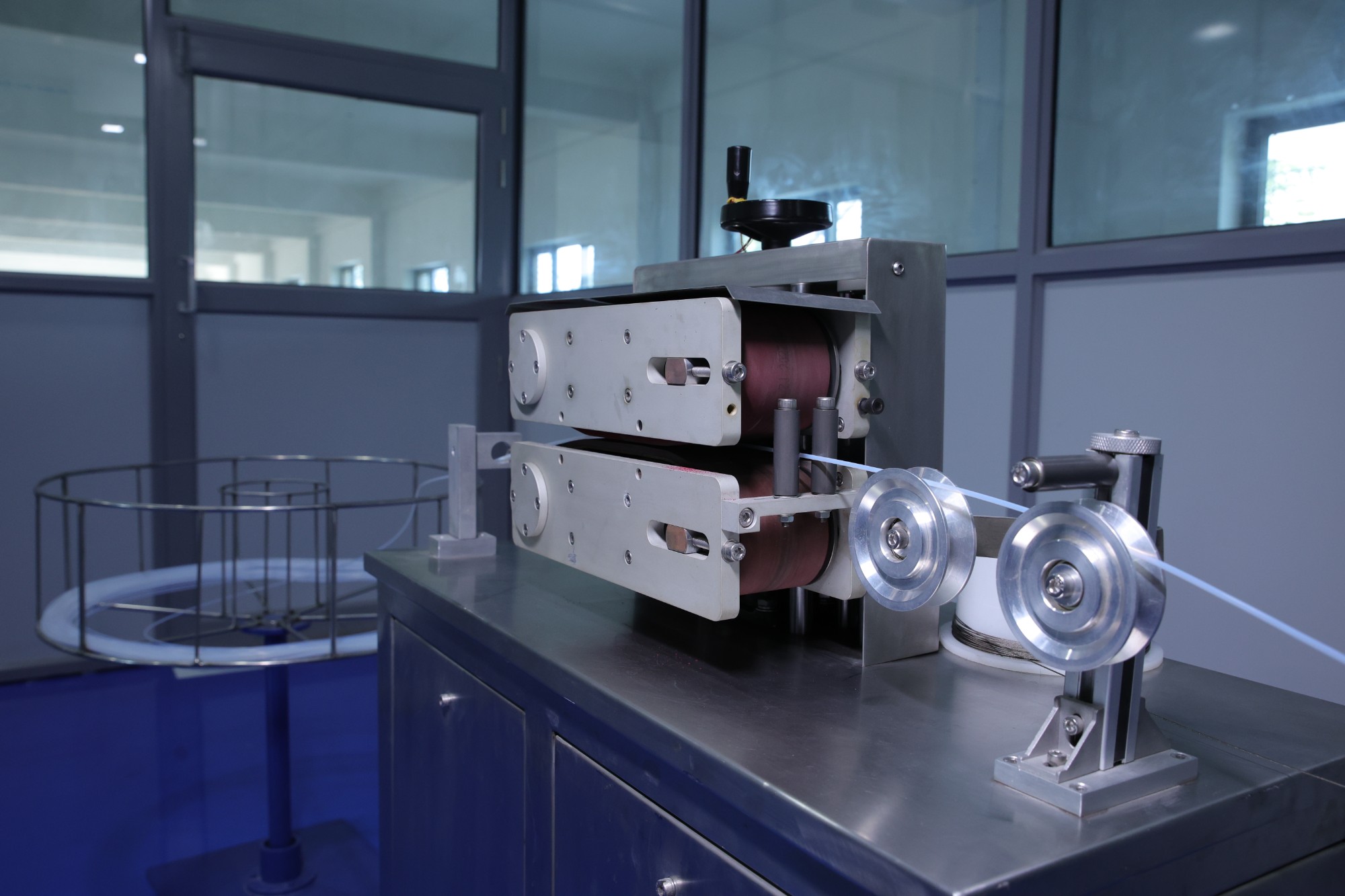

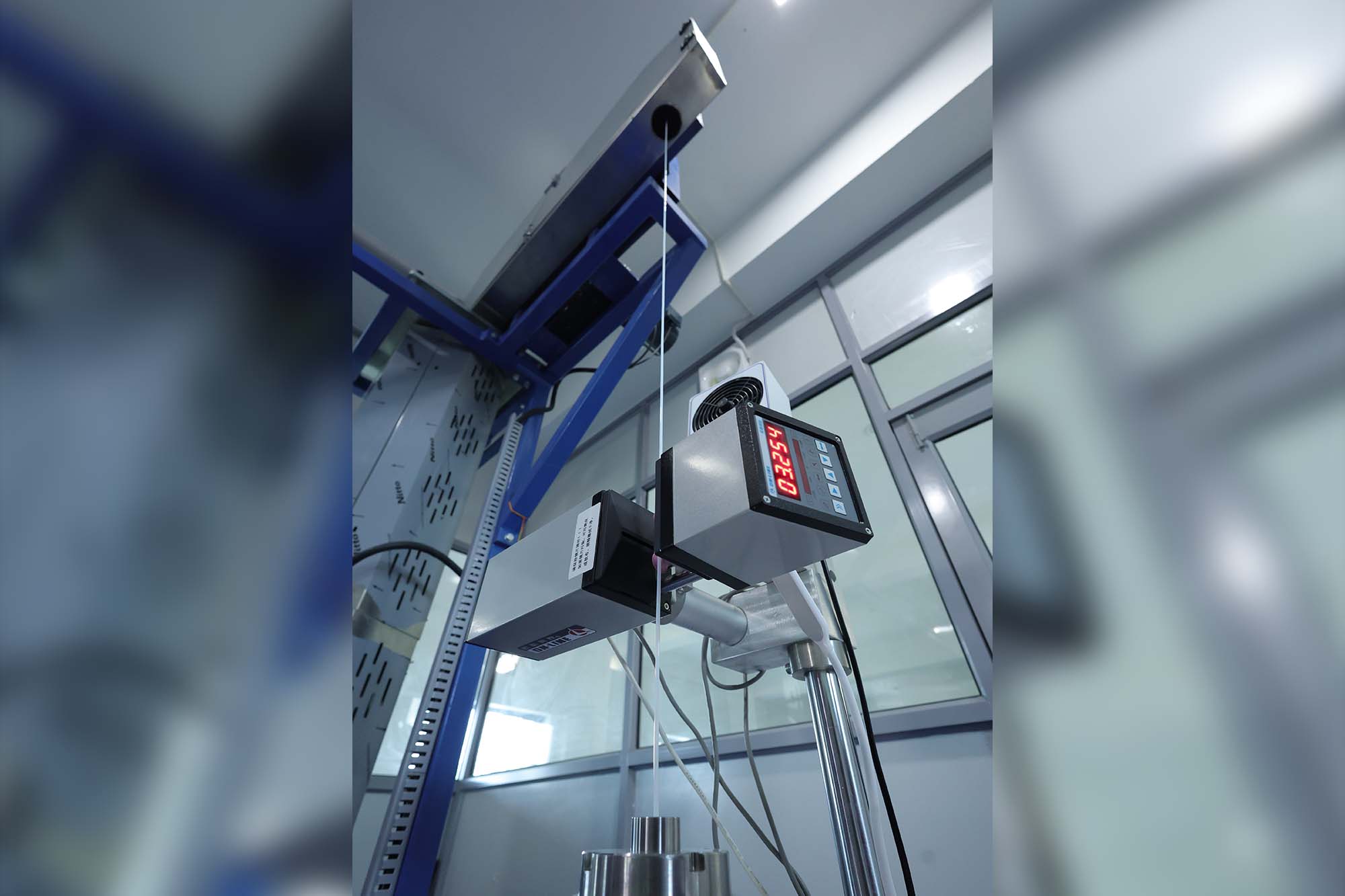

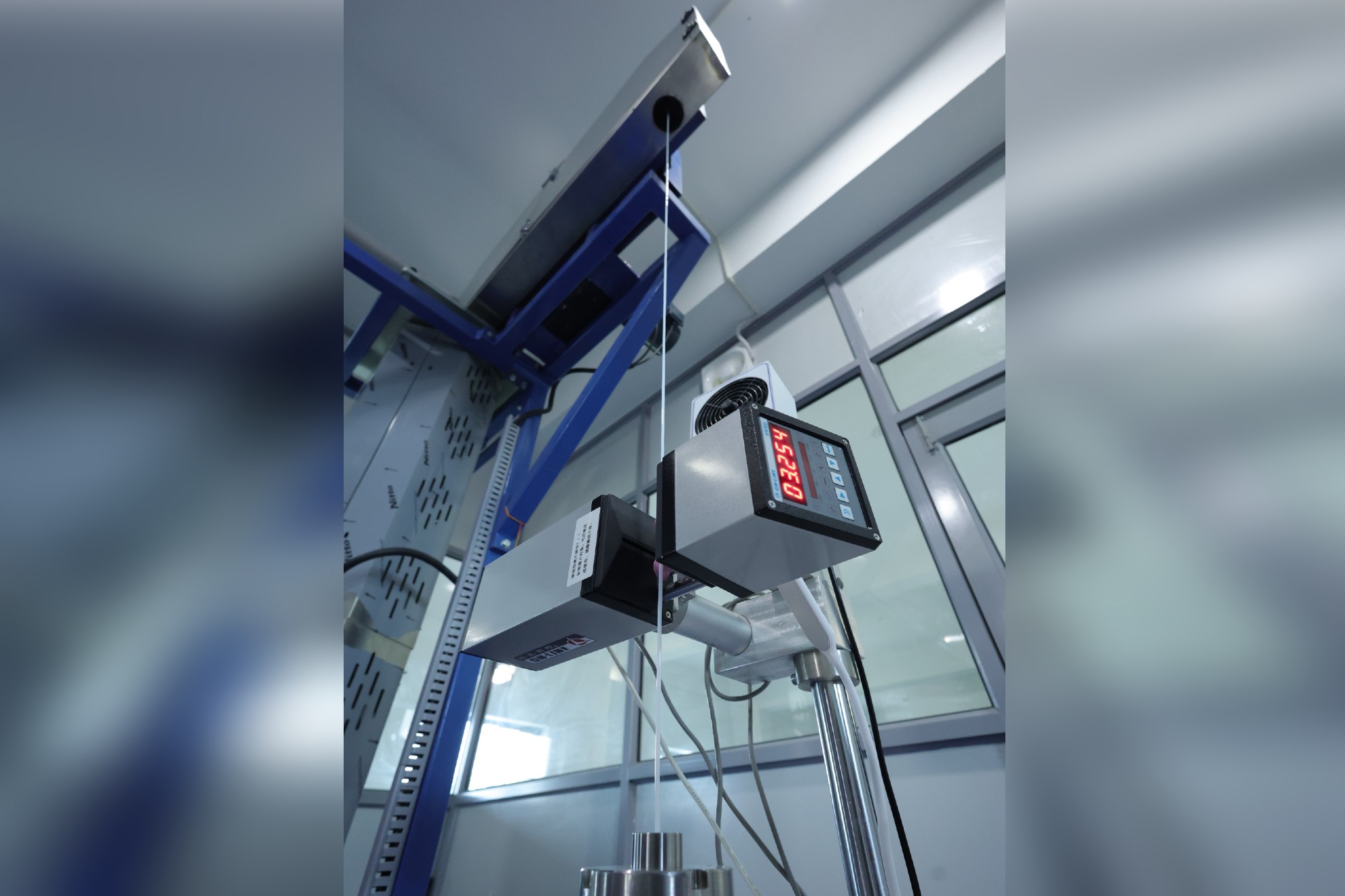

Located in Dehradun, Uttarakhand, Yash Dynamics operates a dedicated manufacturing facility spanning 25,000 sq. ft., equipped with advanced vertical paste extrusion machines and a fully functional in-house quality assurance laboratory. This facility enables the company to deliver consistent, high-performance PTFE tubes tailored to the exact needs of diverse industries.

Yash Dynamics is the first in India to acquire technical knowledge for PTFE vertical paste extrusion technology from the country’s only fluoropolymer manufacturing conglomerate. This unique expertise ensures that all products comply with stringent international standards such as ISO, ASTM, and DIN. Through reverse engineering and rigorous in-house testing, the company guarantees that its tubes meet exacting quality parameters.

Mission

Yash Dynamics aims to empower its clients and partners by providing premium Make-in-India PTFE tubes delivered promptly to their doorsteps. The company is committed to building long-term relationships based on trust, integrity, and mutual respect, with collective growth and success.

Core Advantages

- Premium Quality Materials

The PTFE tubes are manufactured using high-grade raw materials to ensure reliable performance even in extreme industrial conditions.

- Advanced Engineering Precision

With state-of-the-art extrusion technology and strict quality controls, Yash Dynamics ensures smooth finishes, precise dimensions, and tight tolerances.

- ISO-Compliant Operations

Company processes are aligned with ISO standards, and every team member contributes to maintaining consistent manufacturing quality.

- Expert Technical Support

A dedicated team of engineers and technical specialists offer valuable guidance throughout product development and manufacturing stages.

- Customer-Focused Approach

Yash Dynamics works closely with clients to deliver personalised solutions and seamless service from inquiry to final delivery.

- Fast Turnaround Times

With domestic production capabilities and streamlined logistics, the company can meet urgent project requirements efficiently.

Quality

Quality plays a central role in Yash Dynamics’ operations. Every product batch undergoes rigorous inspection and testing to ensure compliance with both domestic and international standards. The company’s in-house testing laboratory verifies technical specifications and certifies each shipment before dispatch.

Application Segments

- Medical Devices

PTFE tubes manufactured by Yash Dynamics offer excellent torque control, pushability, and lubricity. Their rigid substructure helps prevent kinking and supports high-pressure applications in minimally invasive procedures.

- Chemical Industry

PTFE’s chemical inertness and durability make it an ideal substitute for glass in aggressive chemical environments, offering long-term reliability and performance.

- Electrical & Electronics

PTFE is widely used for insulating high-voltage cables and components, ensuring safety and performance.

- Automotive Applications

PTFE tubing is suitable for fluid transfer systems, fuel lines, cable insulations, and mechanical control cables due to its lowest friction properties, broad temperature range (-270°C to +260°C) and excellent mechanical strength.

- 3D Printing Technology

In 3D printers, PTFE tubing guides filament smoothly through Bowden extruders, effectively handling high nozzle temperatures while reducing friction.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.