Precision and performance with PMIKM Actuators

By Staff Report September 17, 2024 12:00 pm IST

In an era where precision and performance are paramount, KM Actuators of PMI redefine motion control with accuracy and power across diverse industries.

The demand for high-performance, reliable, and precise motion control solutions has increased. Whether in automation, robotics, or CNC machinery, the components that drive these systems can be robust and capable of delivering accurate results under various conditions. PMI’s KM Actuators are a leading solution in this domain, offering unparalleled precision and performance for diverse applications.

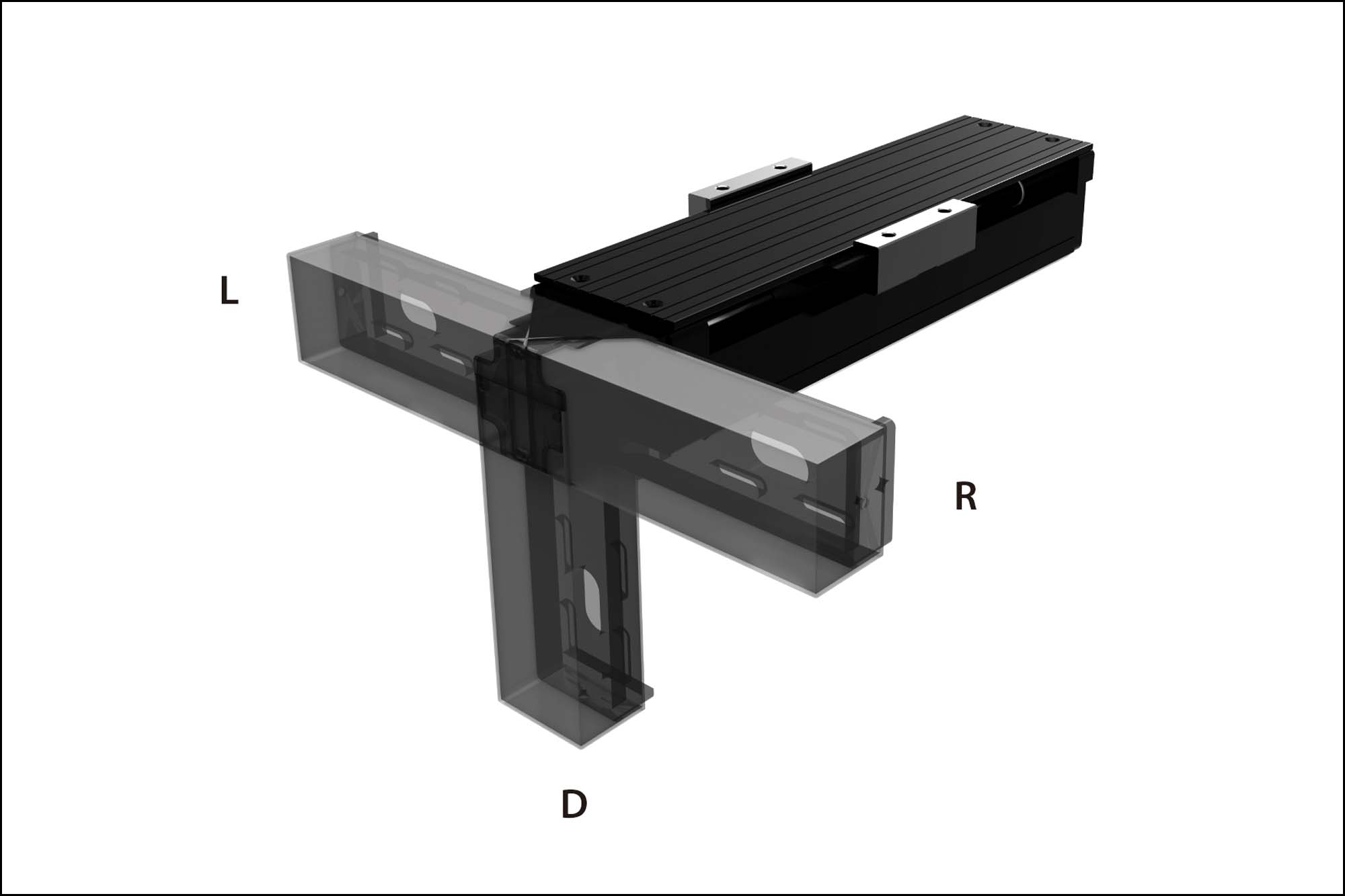

KM Actuator

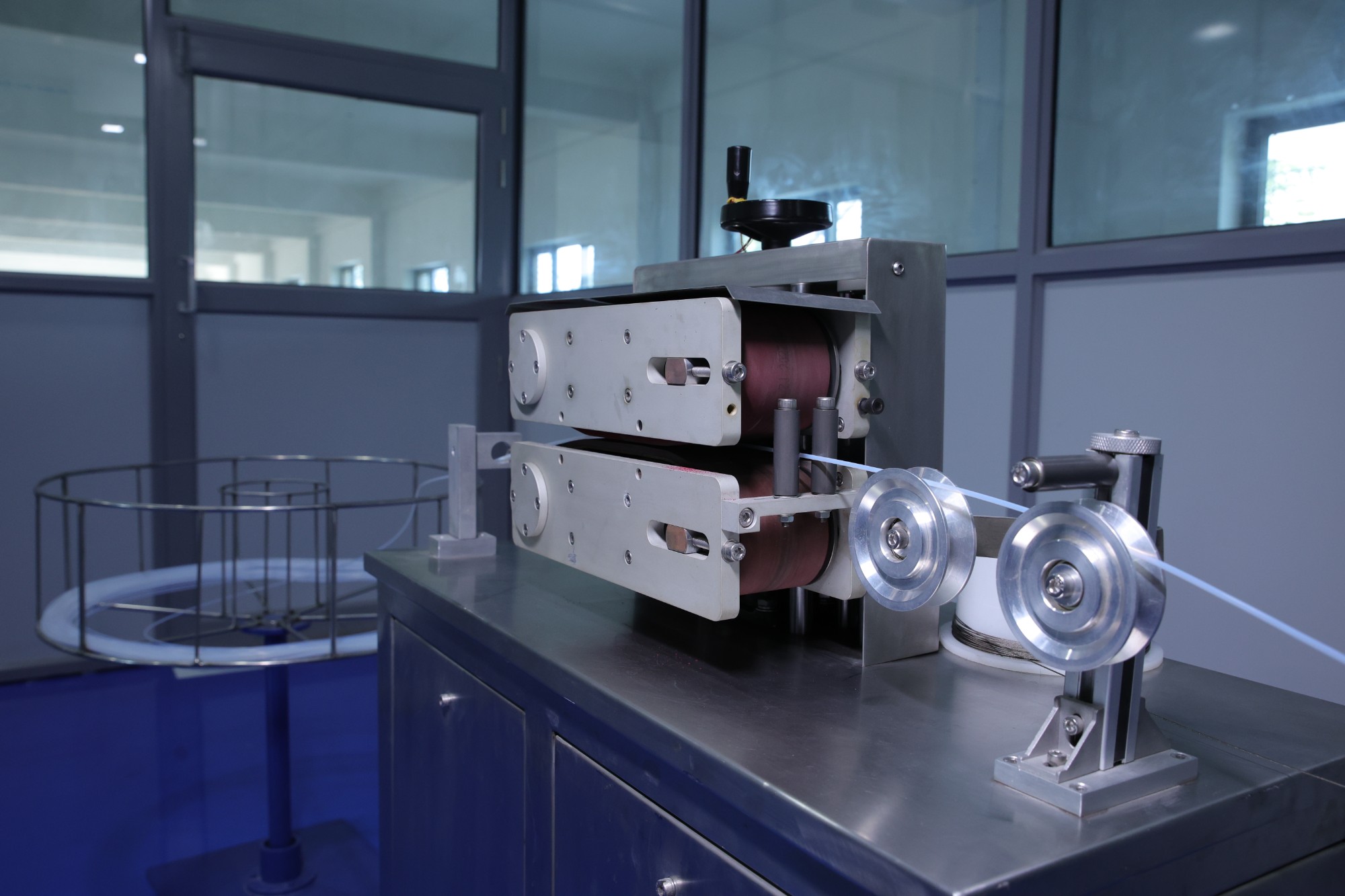

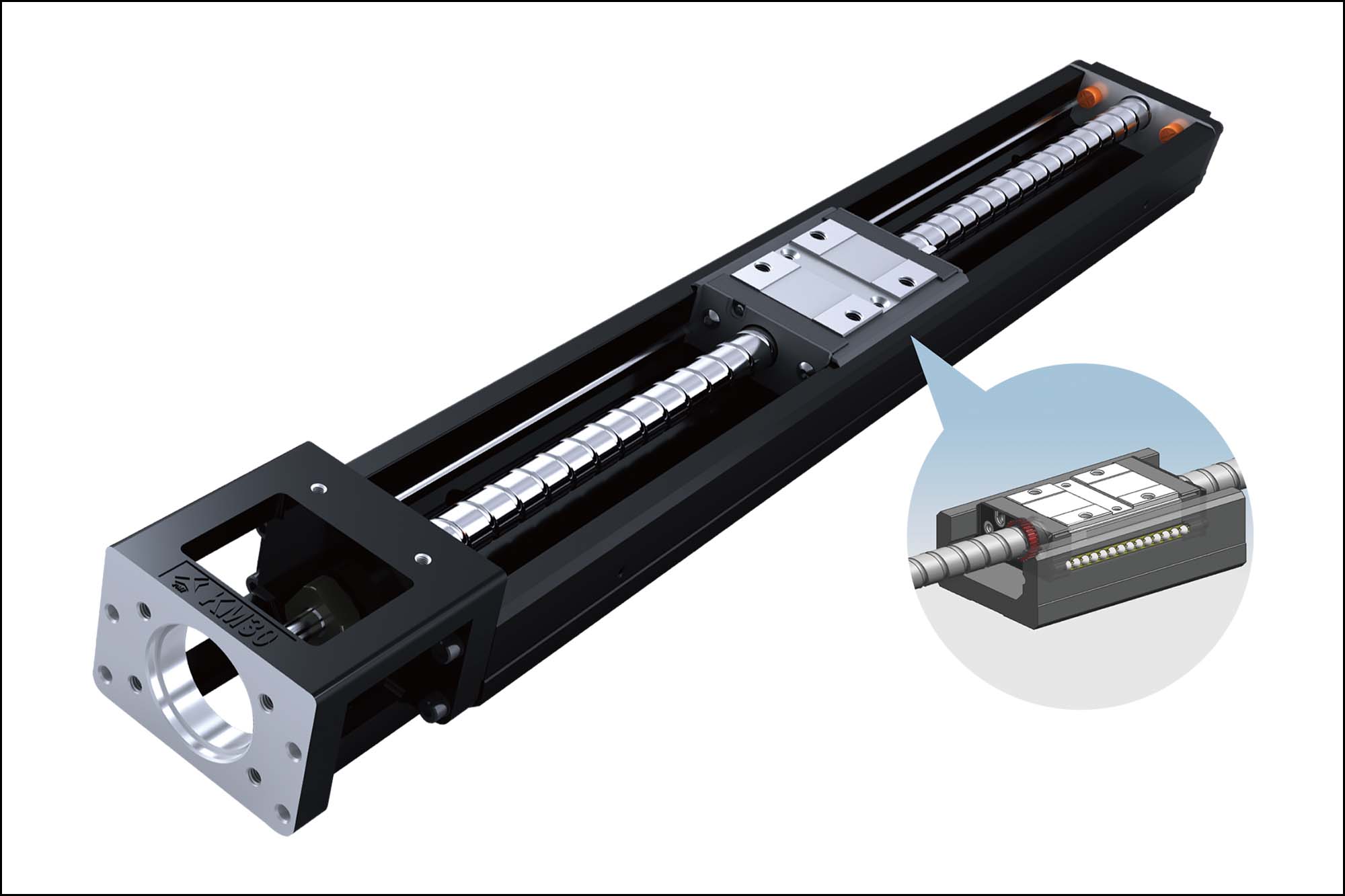

KM Actuators are a specialised product developed by PMI, a global leader in motion control technology. These actuators convert rotary motion into linear motion, a critical function in many automated systems. The design of KM actuators integrates a servo motor and a ball screw. This results in a compact, highly efficient unit that delivers high thrust and exceptional positioning accuracy.

Key Features and Benefits

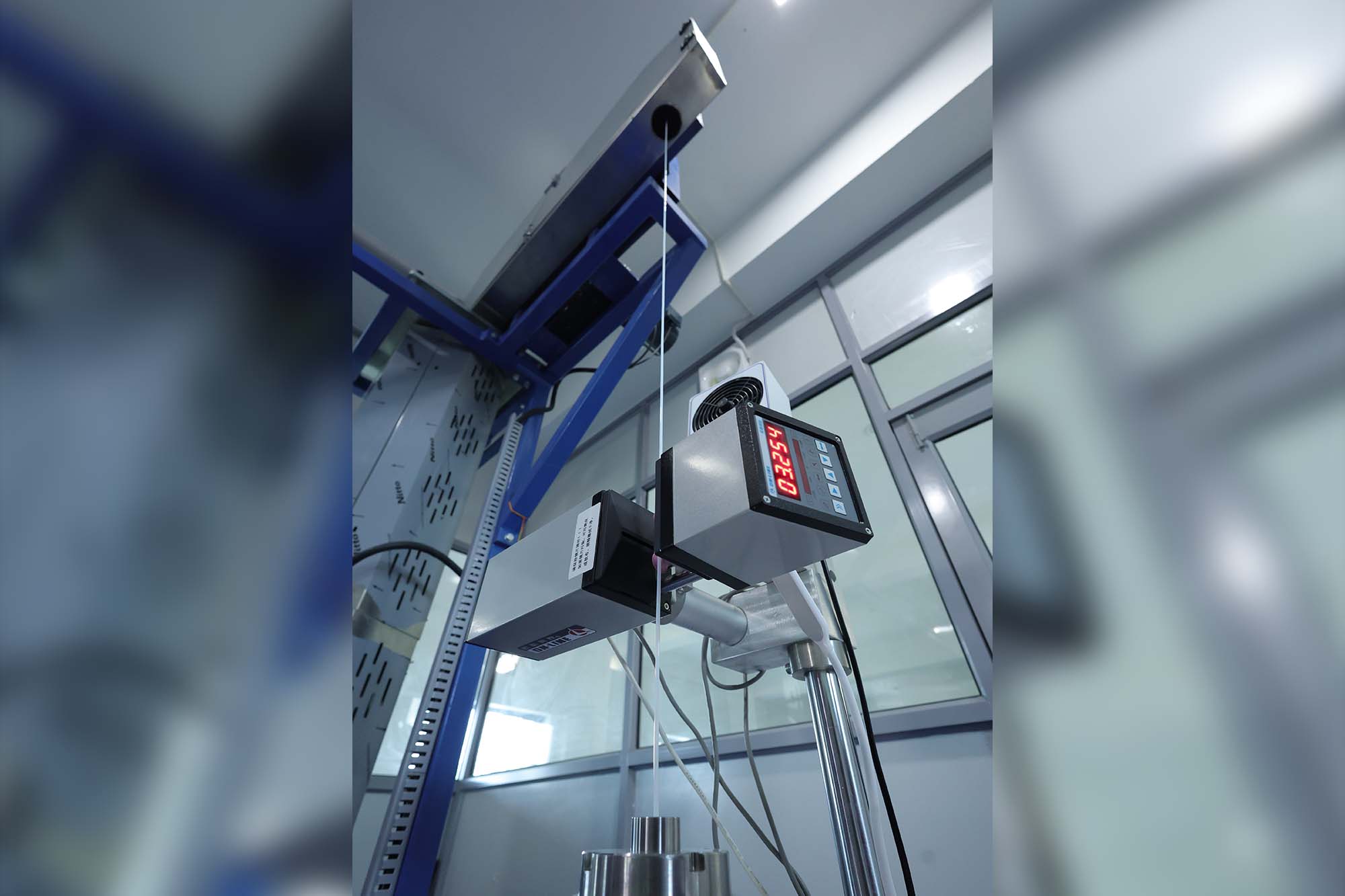

High precision and rigidity: PMI’s KM Actuators are engineered for extreme precision applications. The integration of high-quality ball screws and servo motors allows the actuators to achieve minimal backlash and maintain tight control over positioning. This level of precision is particularly vital in semiconductor manufacturing, where even the smallest deviations can lead to significant quality issues.

Compact and integrated design: The KM Actuator’s compact design is one of its standout features. By combining the servo motor and ball screw into a single unit, PMI has reduced the overall footprint. This makes the actuators ideal for applications where space is at a premium. This design also helps cut downtime and operational costs with simple installation and maintenance.

High thrust capabilities: KM Actuators are built to handle demanding loads. The integration of advanced ball screws enables these actuators to deliver high thrust levels, making them suitable for heavy-duty applications. This capability is essential in industries such as automotive manufacturing, where precision and power must go hand-in-hand.

Versatility across applications: PMI KM Actuators are versatile. From packaging machinery to medical devices, these actuators meet the unique demands of various sectors. Their ability to perform reliably in different environments makes them a favourable choice for engineers seeking adaptable motion control solutions.

Energy Efficiency: The optimised integration of components reduces energy consumption, contributing to more sustainable operations. This feature is important as industries strive to reduce their environmental footprint and focus on energy efficiency.Applications of KM Actuators

PMI’s KM Actuators find applications across numerous industries, including:

Robotics: Providing precise motion control in robotic arms and automated guided vehicles (AGVs).

CNC Machinery: Enhancing the accuracy and efficiency of cutting, milling, and drilling operations.

Semiconductor Manufacturing: Ensuring high precision in placing and handling delicate components.

Medical Devices: Offering reliable performance in equipment such as surgical robots and diagnostic machines.

Packaging: Improving the speed and accuracy of packaging lines for consistent product quality.

PMI’s KM Actuators represent the pinnacle of motion control technology, offering a combination of precision, power, and efficiency. Their integrated design, high thrust capabilities, and versatility make them an indispensable tool. As industries continue to evolve, the demand for such reliable and high-performance actuators is only expected to grow. With its commitment to innovation and quality, PMI is well-positioned to meet this demand, driving the future of automation and precision engineering.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.