Schmalz Vacuum Jumbo Lifters enhance efficiency and employee health in internal logistics

By Staff Report June 19, 2025 6:26 pm IST

Schmalz Jumbo vacuum lifters are helping internal logistics in India by reducing physical strain and improving worker safety across industries through smart, ergonomic, and reliable lifting solutions.

The relentless pace of internal logistics in India—from busy manufacturing hubs to expansive distribution centers—often conceals a silent struggle. Operators continuously contend with the repetitive and physically demanding task of manually handling a wide variety of goods: heavy sacks of raw materials, bulky cardboard boxes, slippery barrels, and awkward buckets and jugs. This ongoing strain is beyond an operational inefficiency; it’s a serious concern for worker health and safety. The impact is far-reaching, from chronic back pain and increased injury rates to a fatigued workforce operating below capacity. These issues disrupt workflows, create bottlenecks, and ultimately affect the bottom line.

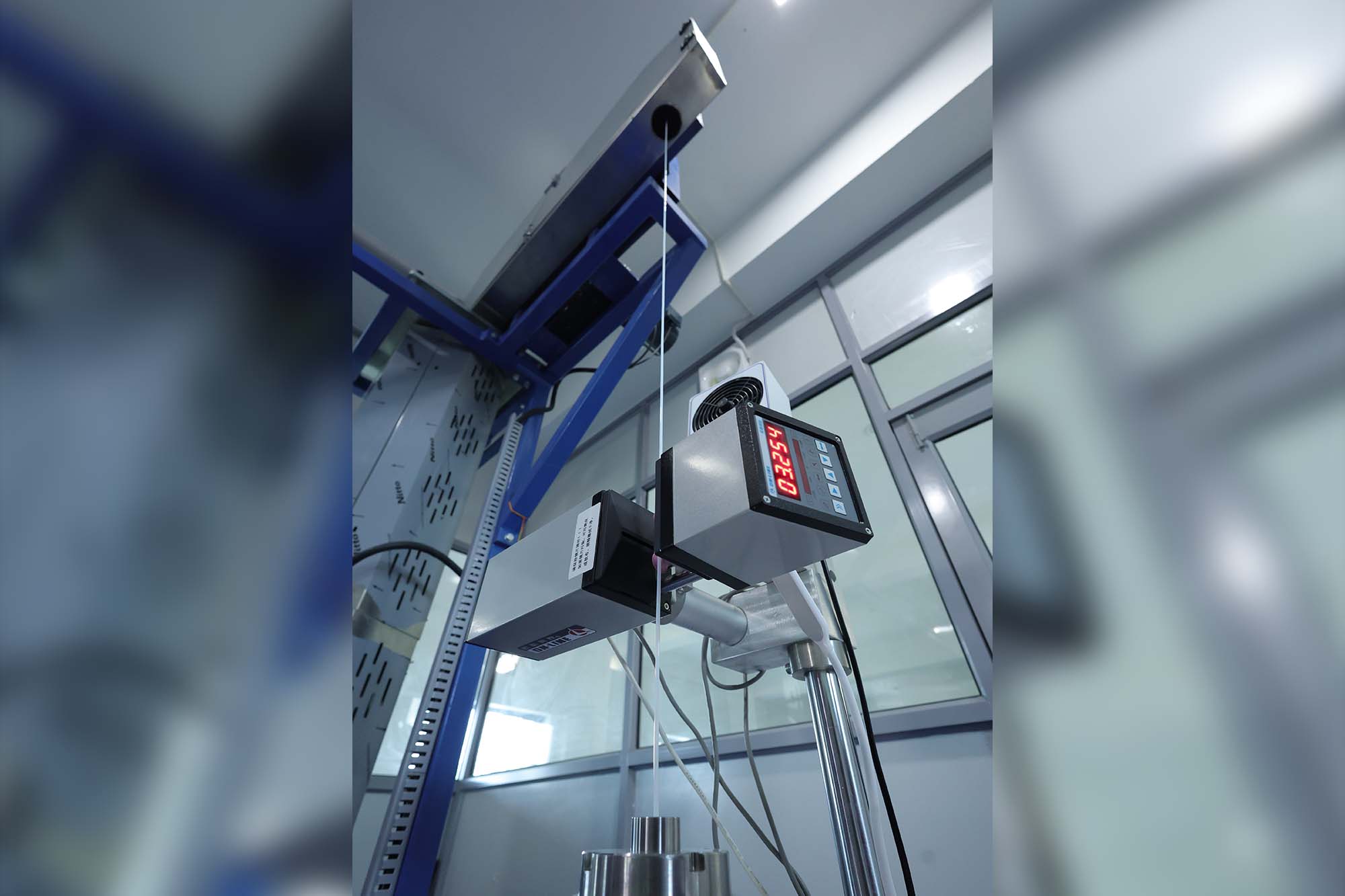

Fortunately, a powerful solution is emerging to break this back-breaking cycle: the Schmalz Jumbo series of vacuum tube lifters. These intelligent, ergonomically designed lifting devices are transforming internal logistics processes across India and globally, offering a safer, faster, and more efficient method for handling a wide range of goods. Using advanced vacuum technology, Schmalz Jumbo lifters eliminate the physical strain of manual lifting, resulting in improved operator safety and a noticeable increase in productivity.

Schmalz, fully aware of the challenges and growing demands of the Indian logistics sector, delivers these innovative solutions nationwide. By understanding local needs, the team provides expert consultation, professional installation, and responsive after-sales service, ensuring the smooth integration of Jumbo lifters into existing workflows. By partnering with Indian businesses, Schmalz India contributes to a safer and more efficient material-handling environment, helping companies enhance their internal logistics while prioritising worker well-being. This strong local presence ensures that Indian industries can easily access and benefit from Schmalz’s cutting-edge technology.

The Schmalz Jumbo series includes several models, each designed to meet specific lifting needs. Among the most widely used are the JumboFlex, the JumboSprint, and its specialised variant, the JumboSprintEX, for hazardous areas.

JumboFlex – Lightweight and ergonomic

The JumboFlex is a versatile, ergonomic solution for frequently handling lighter items weighing up to 50 kg. Its standout feature is its one-hand operation, using an intuitive two-button control that allows the operator to lift, lower, and release loads with precision—even suspending them at any desired height. The comfortable handle design reduces strain and allows for extended use without fatigue. Businesses benefit from faster handling and improved ergonomics, particularly in operations such as order picking and machine loading. The quick-change system enables the use of different vacuum grippers, making the JumboFlex highly adaptable. Optional features, such as a swivel mechanism for horizontal rotation, further enhance its flexibility and help reduce product damage during handling.

JumboSprint – Heavy-Duty performance

For heavier, more demanding tasks, the JumboSprint stands out. It is ideal for frequent handling of compact loads up to 300 kg. The bow-shaped operator handle surrounds the unit, offering excellent force transfer and control when lifting items such as bags, barrels, or rubber bales. Lifting and lowering are controlled by simply pulling up or pushing down on the handle lever, making it easy for a single operator to manage large loads. The modular system includes a wide range of grippers and accessories, along with an optional rotation unit for precise positioning. The JumboSprint also carries the AGR (Aktion Gesunder Rücken e.V.) seal of approval, recognising its role in reducing work-related musculoskeletal issues and improving operator motivation.

JumboSprint EX – Safety in hazardous environments

Addressing safety in potentially explosive settings, the JumboSprint EX is a specialised model designed for use in ATEX zones 1/21 and 2/22. It can handle up to 250 kg in Zone 2/22 and 85 kg in Zone 1/21, offering safe lifting for industries such as chemical processing or paint manufacturing. Like the standard JumboSprint, it features a fully enclosed operator handle for precise control. The system is available as a complete unit, including a vacuum tube lifter and an explosion-protected steel jib crane—making it easier to implement and fully compliant with stringent safety standards. It helps ensure operator protection and uninterrupted, safe operations in sensitive areas.

By adopting Schmalz Jumbo vacuum tube lifters, supported by the expertise of Schmalz India, businesses can directly address the challenges of manual lifting. Workers experience a significant reduction in physical strain, resulting in improved comfort, fewer injuries, and increased job satisfaction. For companies, this results in faster cycle times, improved material flow, and a healthier, more productive workforce. The investment in Schmalz Jumbo will secure the long-term health of users while driving sustainable efficiency across operations in India and beyond.

Contact for questions

Schmalz India Private Limited

Marketing Department

EL 38, J Block, MIDC, Bhosari, Pune 411026

T: 020-69115500

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.