Sustainability with smart gear and drive technologies

By Staff Report August 16, 2025 5:54 pm IST

PowerBuild offers energy-efficient power transmission solutions to transform industrial areas. From high-performance geared motors to intelligent VFDs, the company values efficiency and equipment life to support greener manufacturing practices.

Efficiency and sustainability are basics for the industrialists. PowerBuild, with its decades of engineering excellence, is at the forefront of this transformation. The company has an advanced range of power transmission products that help industries minimise energy consumption, extend machine lifespans, and transition toward greener manufacturing practices.

PowerBuild’s entire gearbox and geared motor portfolio is engineered with energy optimisation at its core. Whether it’s the Series M Helical Inline Geared Motors, known for their compact design and high efficiency, or the Series K Helical Bevel Geared Motors, offering torque up to 50,000 Nm with minimal energy loss, each product is built to maximise output while reducing unnecessary power draw. These solutions are precision-designed to reduce friction, vibration, and wear, which are the three major contributors to energy inefficiency and mechanical failure.

One of the most effective solutions is Radicon, which supports sustainability through its gear systems’ high mechanical efficiency. It directly contributes to lower electricity consumption in continuous operations. For example, the Series C Heli-Worm and Series F Parallel Shaft Geared Motors are designed to deliver optimal performance even under varying load conditions, reducing the stress on motors and associated systems. This conserves energy and lowers the carbon footprint of plants over time.

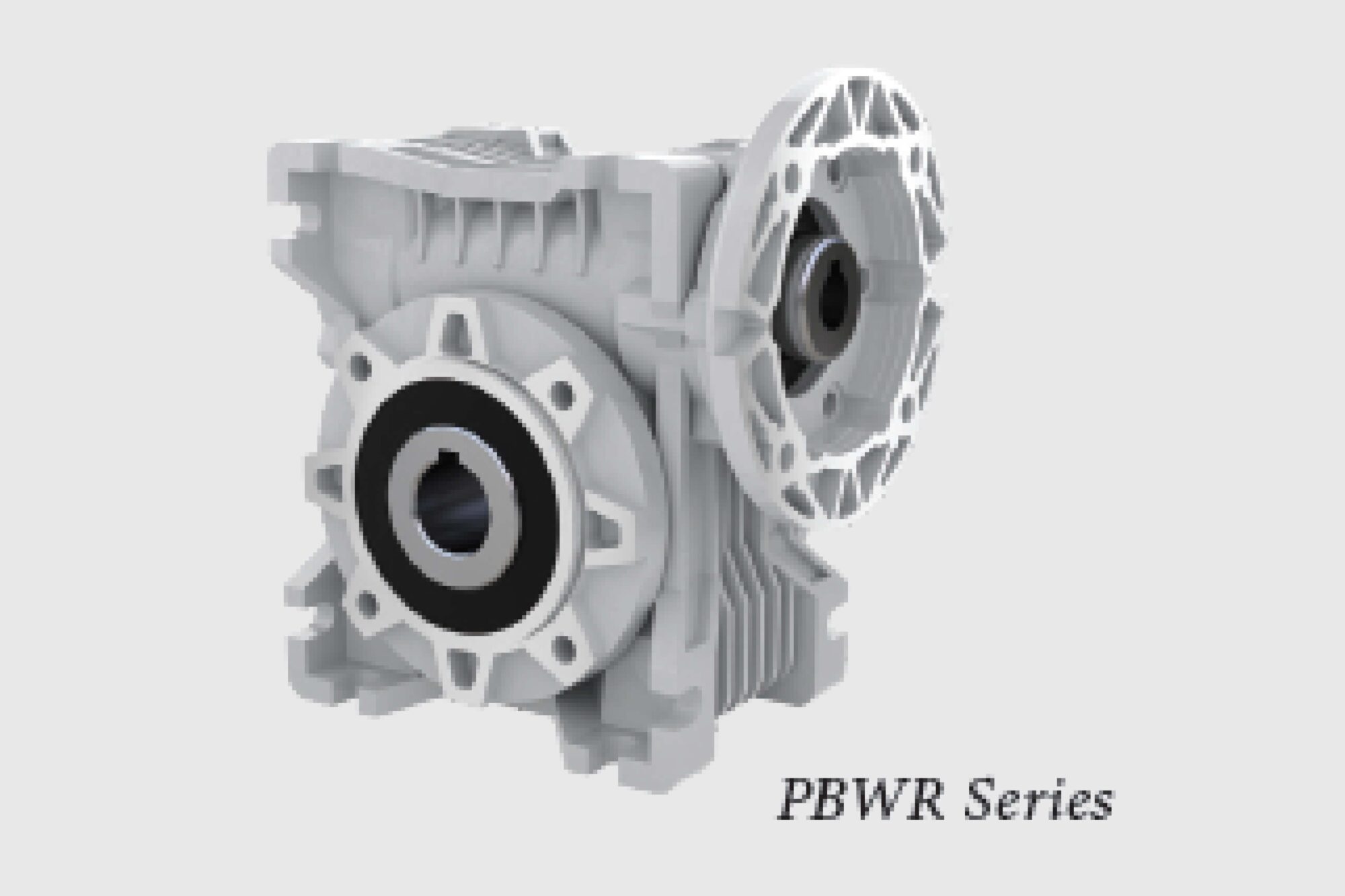

Moreover, PowerBuild’s planetary (Series PL) and worm gear (PBWR) series contribute significantly to space-saving, heat reduction, and maintenance-free operations, all of which are key to sustainable plant design. Many of these gearboxes are pre-filled with high-grade lubricants and designed for long maintenance cycles. This reduces downtime and waste generation to increase the life of the equipment.

To complement its mechanical excellence, Radicon also offers the PBL VFD Series (Variable Frequency Drives), a modern, electronic solution that brings intelligent speed and torque control to the table. These drives allow motors to operate at optimal speeds, reducing excess energy use during startup, operation, and load variations. The result is a finely tuned drive system that aligns with green manufacturing goals.

Lastly, through extended equipment life cycles, Radicon products inherently reduce the need for frequent replacements and resource consumption. Gear units like the Series J Shaft Mounted Reducers and Roloid Gear Pumps are made with durability and long-term efficiency in mind, further reinforcing the company’s commitment to sustainable industry practices.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.