TOF CAMERAS FOR AUTOMATION TASKS

By OEM Update Editorial June 17, 2024 5:47 pm IST

A 3D camera expands the options by sensor systems in intralogistics by another dimension. It allows the camera to offer real-time capture of fill levels or a comprehensive view of the process. In addition, it can also be used as the ‘eye’ of IIoT applications, allowing it to determine KPIs such as ‘Overall Equipment Efficiency’ (OEE).

Automation of intralogistics processes requires that the current status, e.g. the location of containers or their fill level, be recorded as precisely and promptly as possible. It is where high-performance sensor systems come in, and automation tasks become ever more demanding. Ultimately, a precise image of the current status is essential. The subsequent steps in the processing, assembly and handling of products, containers and packaging units can be initiated.

Trend: the replacement of traditional sensors with cameras

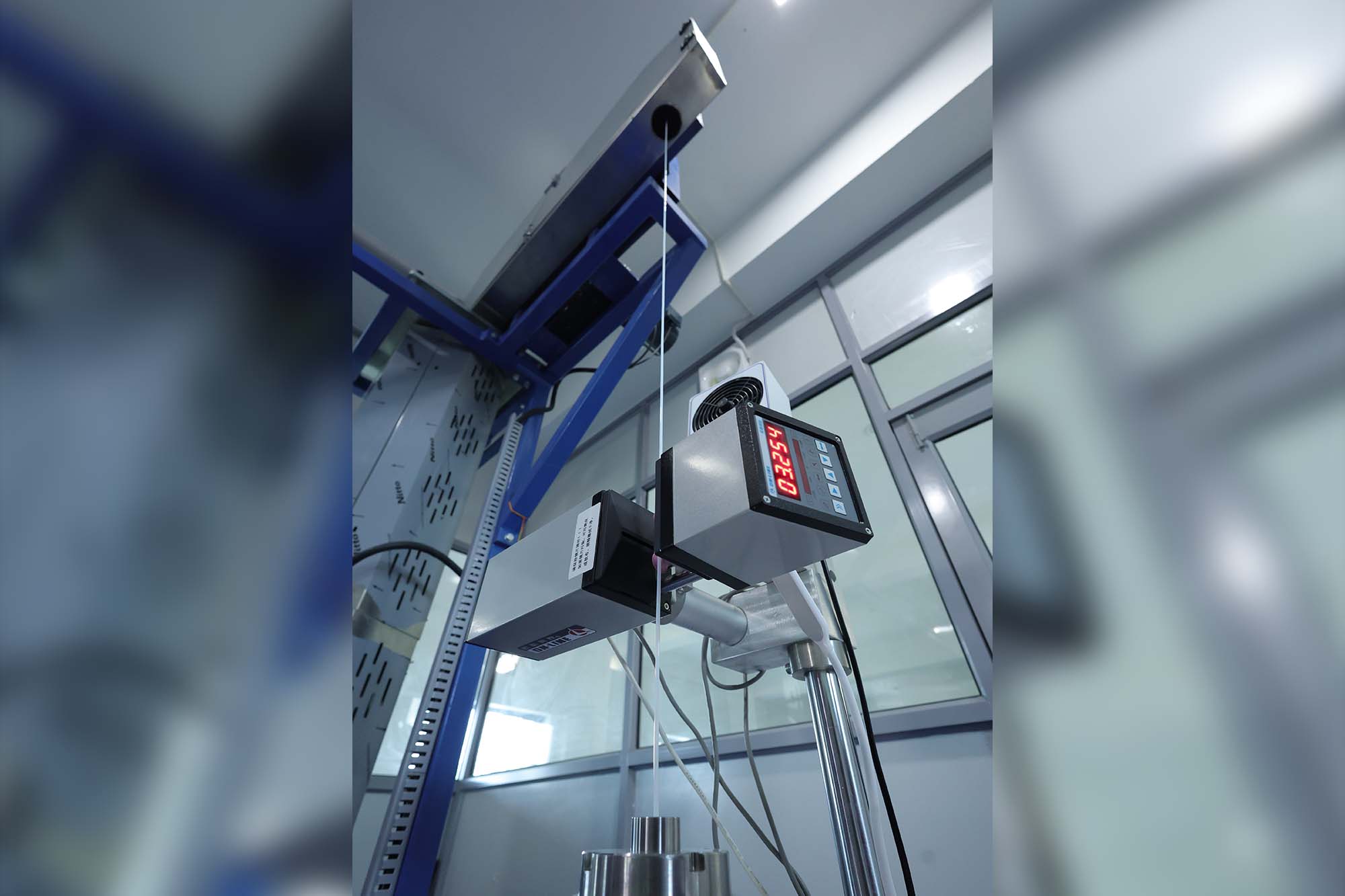

In many applications, cameras are replacing traditional industrial sensors (magnetic, inductive, laser-based, etc.). Development is now going a step further. While cameras and image-processing systems generate two-dimensional images, the first industry- standard cameras now offer 3D depth images with millimetre accuracy. These include the AM-T100 from Schmersal, a 3D camera for automation technology.

Trend: the replacement of traditional sensors with cameras In many applications, cameras are replacing traditional industrial sensors (magnetic, inductive, laser-based, etc.). Development is now going a step further. While cameras and image-processing systems generate two-dimensional images, the first industry- standard cameras now offer 3D depth images with millimetre accuracy. These include the AM-T100 from Schmersal, a 3D camera for automation technology.

Usage examples: contour control and fill level monitoring

Thanks to a high frame rate of up to 60 fps, this type of 3D ToF camera can determine the positions and dimensions of objects in real- time, e.g. the position and stacking height of boxes palletized by a robot or the contours of a container or box. It requires no more than a single recording.

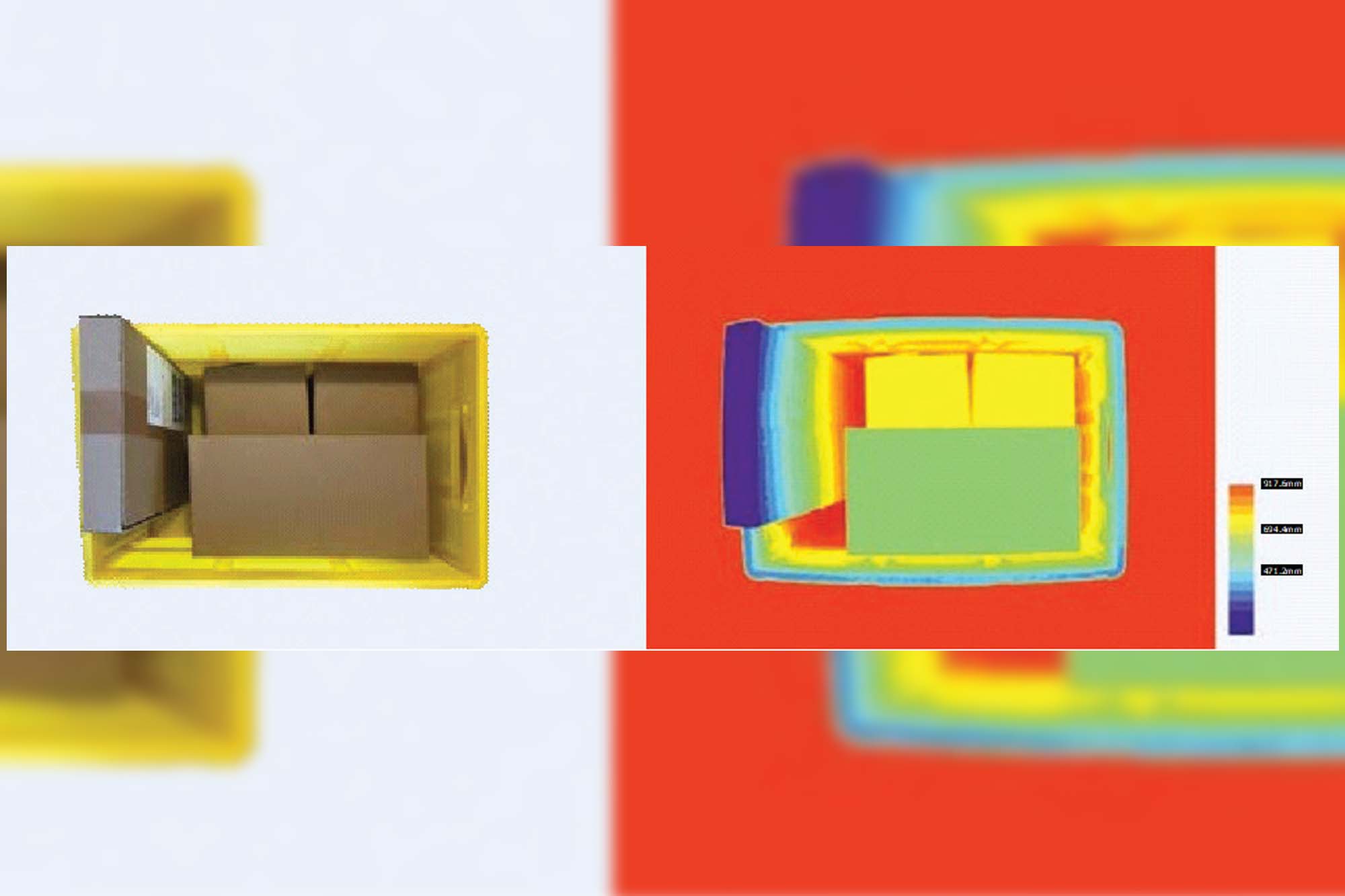

The camera can also ‘look’ into containers or heavy load carriers to determine their fill levels. It can also be used to determine the volume of piece goods and monitor staging areas in production, assembly, storage, and order-picking from a ‘bird’ s-eye view’. Other areas of use include capturing dimensions and surface quality in a 67° x 51° field of vision at a range of 6 meters.

Real-time data evaluation, simple configuration

The added performance of the 3D camera is thanks to the pre-installed CONSAM-T software. It allows the AM-T100 to be configured to monitor complex and individually defined 3D zones, both in real-time and as moving images. It detects an object within these zones and sends a signal to switch digital outputs. You can also switch back and forth between different 3D zones via digital inputs. An integrated SDK (Software Development Kit) supports software developers and system integrators with camera configuration and software application creation. It opens up countless usage opportunities in automated intralogistics. High-performance algorithms enable data pre-filtering. The camera can be adapted to different environmental conditions. The captured image data are transmitted via the standard GenICam data interface and can thus be evaluated by common image processing software. An Ethernet interface enables fast and rich data transfer and, if necessary, a 24 V energy supply via Power over Ethernet.

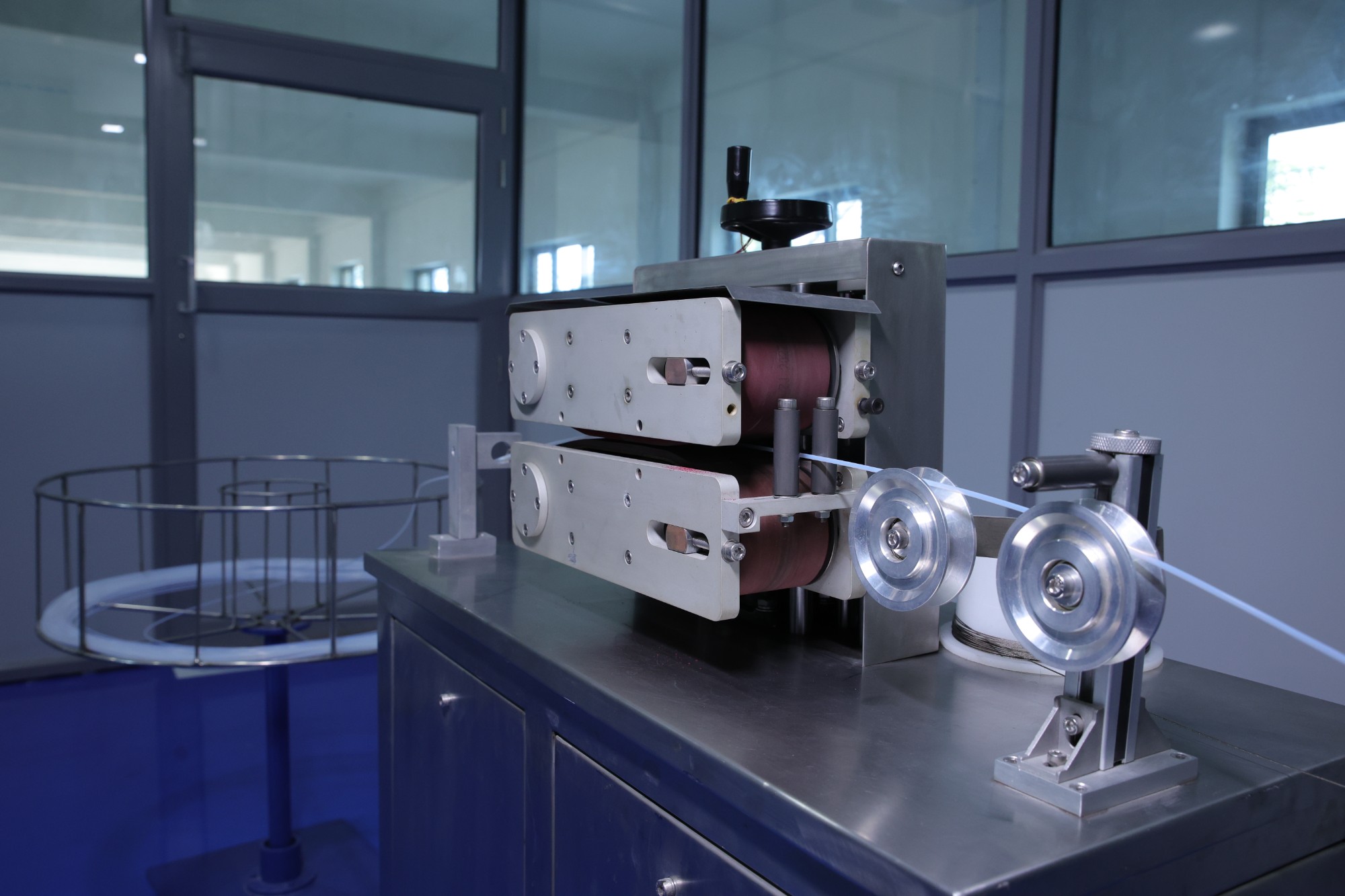

Demonstrator for IIoT application at IWS

Schmersal will demonstrate the new 3D camera at IWS in Yashobhoomi, New Delhi, in an intralogistics IIoT application demonstrator. The two cameras will capture each container’s contours and fill level and transfer the data to a safety controller, where they will be saved and analyzed with image-processing software. A dashboard will display the results, and an alert will follow if limit values are exceeded.

With these data, further processing software can determine the ratio of good TOF CAMERAS FOR AUTOMATION TASKS A 3D camera expands the options by sensor systems in intralogistics by another dimension. It allows the camera to offer real-time capture of fill levels or a comprehensive view of the process. In addition, it can also be used as the ‘eye’ of IIoT applications, allowing it to determine KPIs such as ‘Overall Equipment Efficiency’ (OEE). CASE STUDY A 3D look into the container to determine its fill level.) The ToF camera offers a three-dimensional image of the automation process with a single sensor. CASE STUDY June 2024 n 13 to bad parts or deviations from visually detectable default values and incorporate these values into production-related KPIs (Key Performance Indicators). The approach also makes it easy to determine ‘Overall Equipment Effectiveness’ (OEE).

From the controller to Edge Gateway with OPC UA and to the cloud

Schmersal’s IIoT demonstrator allows the data determined by the cameras and evaluated in the on-site controller to be forwarded to an Edge Gateway via OPC UA and then onto a cloud infrastructure. There is then an integrated chain of information, giving users several options in use, as well as transparency.

New components for the safety of machinery As one would expect from Schmersal, safety functions are integrated into the demonstrator, including via a new version of the Safety Fieldbox, which allows up to eight safety switchgear devices to integrate into the safety circuit at field level. Safety Fieldbox variant can communicate via the PROFINET/ PROFIsafe protocol as before and via EtherNet/IP with CIP Safety and EtherCAT with FSoE. The designer can configure the machine’s safety functions independently of the Fieldbus system, as the three variants cover the maximum range of control systems used internationally.

The safety-oriented data are not sent to the cloud but evaluated by the safety controller. At the safety of machinery level, integration at the data level is also progressing, offering an advantage for intralogistics systems given the often extensive nature of the system, the need to protect a wide range of hazardous areas and the variety of different types of safety switchgear device used (electromechanical, sensors, optoelectronics). Safety Fieldboxes and safety-oriented bus systems, in conjunction with modern safety controllers, allow these tasks to be designed more efficiently and be better adapted to the individual application.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.