MHE Automation for Modern Manufacturing

By OEM Update Editorial November 1, 2022 12:04 pm IST

Industry experts share an outlook on leveraging integrated process automation and options like AI/ ML and how integrating innovative automation technologies in material handling solutions is helping India to become a global manufacturing hub, bringing in productivity.

The imminent need for manufacturing organisations is to integrate AI and machine learning into manufacturing operations. Further, modern manufacturing with digitalisation represents a transition from traditional automation. Choosing the proper automated material handling and parts sorting system has increased the speed of the process. Thus, suitable capacity planning needs to be done. AI / ML can dramatically help business processes to improve and adapt to changing business conditions. In a warehouse, most activities happen repetitively. Thus AI/ML can make intelligent decisions on improving the forecast for handling future growth, resource optimisation, labour management and productivity improvements.

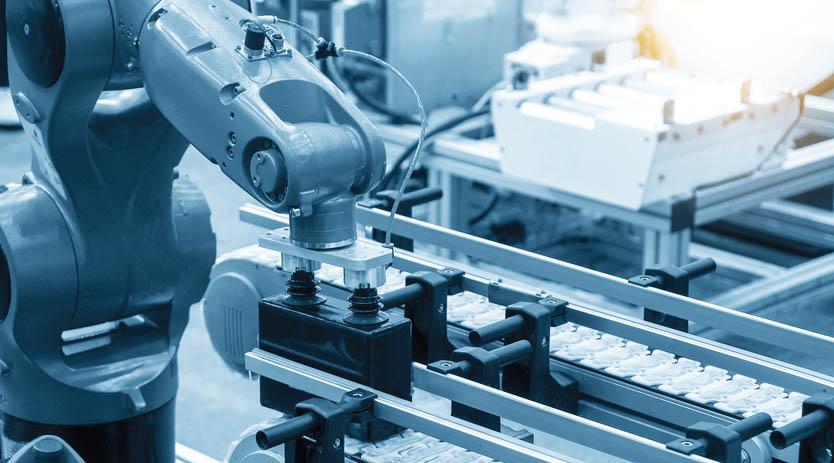

Modern manufacturing aims to have machinery and equipment networked to bring transformation. Robotic use is growing at an exponential rate in the manufacturing industry. Programmable automation without human intervention is being utilised for machine operations. Machine Learning and AI provide real-time and predictive analytics that facilitate manufacturing operations to improve quality and reduce downtime— automating the process results in smooth production and high-quality products. In contrast, material handling and storage selection is based on production capacity.

Today, the dynamic of automation has shifted towards integrated process automation and integrated material handling. That means all or most processes are automated, like material receiving, checking, sorting, palletisation, storage, retrieval, order picking, consolidation, sequencing for dispatches and many more, depending upon the business models with various automation technologies.

Make-in-India and IoT impacting material handling business

The industry is rapidly expanding, and imported systems are prohibitively expensive for the sector. According to Mr. Ravichandran D., Senior Manager for Product Management, Messer Cutting Systems India Pvt. Ltd., “Many smart factories and manufacturing units are taking up locally made metal handling systems. These companies are developing material handling systems in India, similar to making in India, for the world.”

Small smart factories are no longer a pipe dream. The optimisation will remain an ongoing process. Voicing his opinion. Mr . Rohit Sadaphal, Program Manager, MCIE Automotive, stated, “Smart factories are using innovative MHE technology to minimise downtime. Smart factories are envisioned as an entire industry 4.0 technology factory.” The smart factories produce parts or provide services and data for continuous improvement. This allows for data analysis and further decision making with the help of collected data to increase productivity.

Speaking in the context of the current scenario analysis, Mr. K. Srinath, President of ISA and Vice President of Mac Machine Tools & Automation, says, “Increasing robotic uses in manufacturing will enhance productivity for MHE operations. Most of the material handling is contract labour, improving efficiency and productivity.

The crux of the issue is that contract labourers are not permanent employees, and it’s not guaranteed that they will be available on the manufacturing floor daily. Most customers are forced to automate because of perfection. However, the reality is that people do not find manufacturing to be an easy job these days because Uber or Swiggy is a much more appealing proposition for them to work for the same pay. Secondly, they are free and can do whatever they want.” “Most manufacturers can solve this issue by planning to incorporate robots in their processes. And the efficiency will improve as the robots keep going.”

Opportunities for automated material handling solutions and opportunities

Mr. Suunil Dabral, Senior Vice President & Business Head of Körber Supply Chain Ltd., vividly explains, “Automated material handling systems are viewed as process and efficiency enablers in an industrial warehouse; the warehouse within a factory, a distribution centre, or an order fulfilment centre. These systems and technologies ensure efficient movement, beginning with raw material entering the warehouse, sorting and storing, retrieved from storage, and taken to the production line. Then it is converted into finished goods before being moved to storage for direct dispatching in the market. All of these activities and different processes take place within the manufacturing setup. All these activities are taking place today and increasing with the adoption of automation. As a result, automated material handling has a broad definition. However, it essentially denotes accuracy and picking speed – the speed at which it moves within the warehouse and efficiency gained by reducing errors.”

“Material handling automation has grown rapidly. And it’s moving in a direction that we couldn’t have predicted ten years ago: the intelligence of these machines is becoming intelligent”, says Mr. Suunil. The Indian manufacturing sector is growing at a CAGR of around 7-10 percent, which is relatively low. Growth is slow for obvious reasons, but it also has its challenges. According to one McKinsey study, 70 percent of Indian manufacturing companies cannot generate returns more significant than their cost of capital, implying that their value is diminishing. So, all of the challenges in the sector include higher infrastructure and input costs such as labour cost, unskilled labour etc. The related deficiencies and damages occurring by employing unskilled labour, poor logistics, need for infrastructure lead to delays and higher inventory costs.

Mitigating challenges

The rising cost of power and fuel is currently overwhelming due to the war situation in Europe. There are inherent challenges in any value chain or industry. It is predicted that over the next seven years, the Indian manufacturing sector will generate additional manufacturing Gross Value Add in the range of $300 billion, with ten different manufacturing clusters producing this GVA collectively. The government has also launched a PLI scheme that targets 14 different sectors to boost Indian manufacturing growth. To help the sectors generate more efficiencies in manufacturing,some of the challenges can be addressed by using automated material handling systems, keeping low inventory costs, faster production, goods leaving the warehouse and reaching the markets in the shortest time possible, and minimal or no return logistics costs.Consequently, automation will supposedly catalyse the growth of Indian manufacturing sector.

Way out for SMEs and MSMEsElaborating on his viewpoint, Mr. Suunil says, “certain challenges are beyond our control. For example, a manufacturer from an SME group can improve the efficiency of operations and derive greater value from investments. However, a way to be found to reduce the cost of power and electricity; improves warehouse performance and, with the same facility and a smaller investment, generate more value for the company. Be aware of technology to deploy in a warehouse or manufacturing setup to add value to a company. This should be the viewpoint of the SME sector.”

Solutions to reduce downtime of MHE installations

Mr. Ravichandran says that “It’s not actually intended for equipment, but it could be for a series of machines based on the layer because of interaction. It’s always a modular concept that can be integrated with existing machines on a shop floor.” And it has different types depending on the plate or sheet metal industry, for the pipe industry or pipe cutting industry. As a result, these systems can be highly configurable for the shopfloor layout, not just for equipment catering to specific equipment. When discussing smart factory solutions for material handling, one of the aspects is a dynamic shopfloor simulation. Mr. Rohit Sadaphal, Program Manager, MCIE Automotive, elucidates, “Digital twin is gaining a lot of currency regarding product design and aspects. A similar new thing is on the way where we can simulate the entire load value engineering.” He remarked, “Material handling equipment has a lot of potential, so a lot of value and human efforts go into metal handling and equipment presses to install a lot of automation on the machine for material handling per se. The smart factory or a warehouse is where the next real transformation will be triggered.” The challenges for MHE adoption for a smart business are infrastructure costs, labour costs and capital input.

The transition from an investment perspective

Mr. Srinath explains, “The first challenge we face in deploying modern material handling equipment is its feasibility. Because, in most existing factories, or if it’s a new factory, they decide from the ground up what needs to go in and how it needs to be planned. In most plants, the infrastructure, like the parts, pallet sizes and varieties, must first be streamlined before much of the material handling automation can begin. The challenge is the feasibility and technical ability to perform successfully in the early stages of adoption. It will not encourage more people to take the risk of investing because investment only pays off when it works the challenge.”

Following that, the majority of people’s mindsets need to be evaluated. The single dimension approach to evaluating a project and the lack of a strategic approach frequently prevent these early-stage technologies from being cost-effective. The ROI may be less appealing or reduce costs when volumes increase, but volumes will only increase if costs decrease. However, most of the time, automation is required because the operation could be more sustainable. Because labour cannot deliver or may not be available, it is time to automate because delivering at that efficiency is the requirement.

Many such challenges are human-centred and cannot be solved by humans. “If a human can solve a problem, it is the priority. However, if this is not possible, evaluate it from a broader strategic perspective, showing the big picture. That will implore you to invest in these technologies. The cost will fall when you invest in these technologies, allowing more people to invest. So it’s a cyclical solution to this problem,” emphasises Mr. Srinath. Material handling plays a significant role in any industry. A transition is happening. The local Indian manufacturing companies, and family-based businesses, have gone for automation. And there are big multinational companies that have excuses not to go for automation. Returning warehouse automation is changing the country’s entire landscape in terms of material handling. And this is the future.

Attributes to align with the future automation

Customers prefer complete material handling solutions for their business needs rather than Material Handling equipment for one task. Some attributes are needed to align with future automation. “When automation was introduced in the industrial sectors, the trigger point was to automate those processes which were difficult to handle manually. Say the manual handling would have made the process slow and inefficient. Thus to add speed and improve the production process, specific automation was adopted, largely to move material from point A to point B or lift and move heavy material or pallets within the manufacturing plants”, says Mr. Suunil.

In this age of smart production lines and factory automation, industrial robots are applied to perform extremely dangerous tasks, improve flexible manufacturing, reduce manpower cost and save development time. Mr. Manish Walia, Head, Automation Business, India, Delta Electronics says, “Cobots are simply robots that can do tasks requiring human flexibility and dexterity. Warehouse cobots help warehouses save money by maximising human work. Collaborative robots are revolutionising the robot-human connection throughout the whole logistics and warehousing business. There are no infrastructure changes necessary for introduction and use of cobots in an organisation. For moving goods AGVs are now able to perform many tasks within warehouses. Their compact size in particular addresses the challenges posed by e-commerce.

As the business volumes are growing, the number of transactions has grown, and the product range has evolved with numerous SKUs and product variations. Thus, you can only expect to hire a few labourers in the warehouses to walk around to pick up the material without errors. Correcting an error takes a lot of time, which is just a waste of productive time. Hence automated material handling solutions can reduce or eliminate mistakes and increase the productivity of the warehouse’s multi-folds with even a smaller number of labours.

The concluding outlook is that the modern and smart business must check what technologies are helpful for their kind of business, volume and growth plans. Looking into the future, the trending technologies, which are industry 4.0 compliant, can be evaluated. Artificial intelligence-based systems will further improve the efficiency of material handling, and these smart, automated systems can analyse the data generated over the years to predict future growth.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.