Scale-up Manufaturing

By OEM Update Editorial June 5, 2024 11:56 am IST

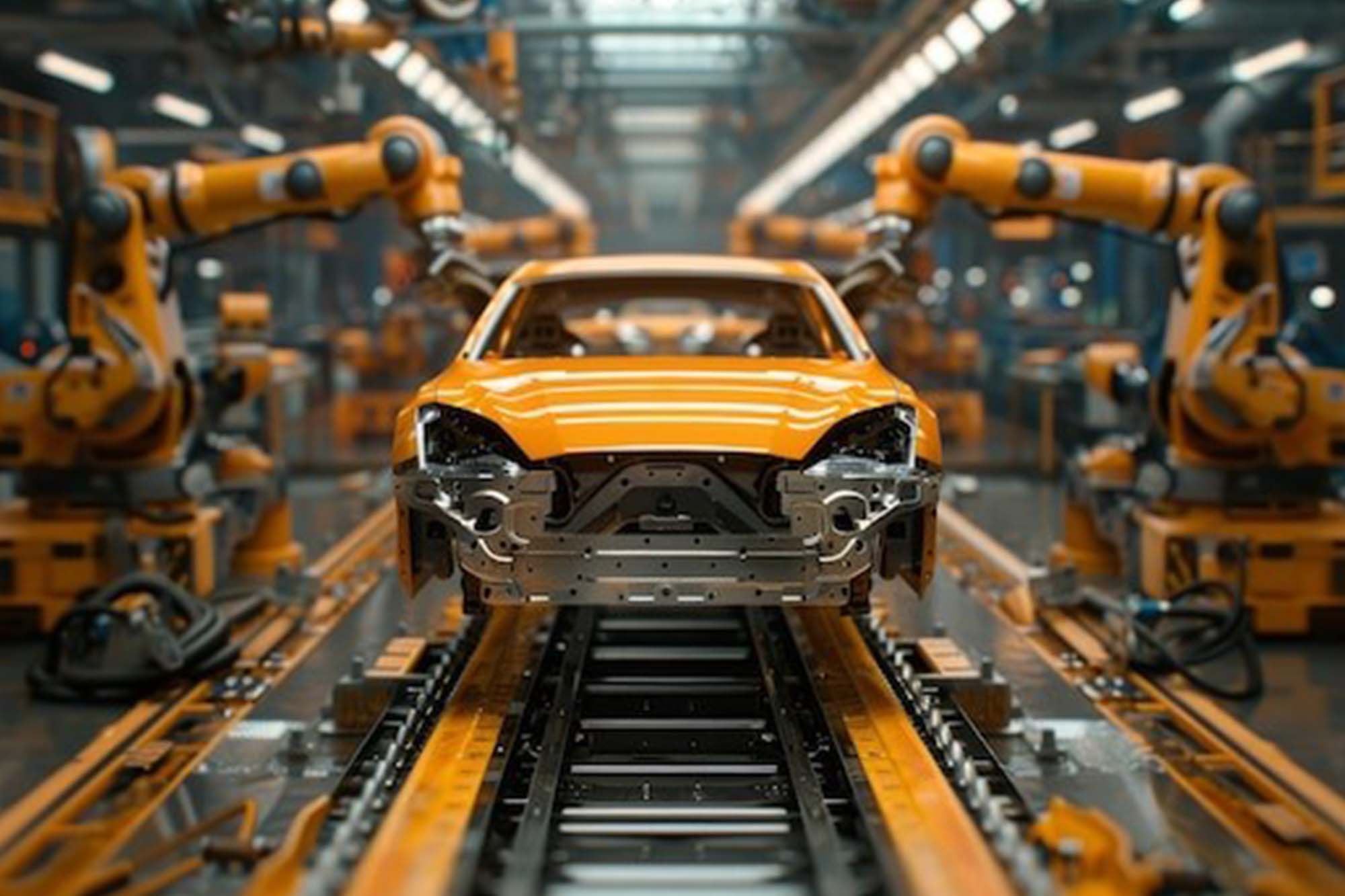

What next? Every business stumbles with this question when they achieve a vertical line on the growth axis. Rounding this to manufacturing, scaling up production is a common goal for businesses looking to meet growing customer demand, expand into new markets, or capitalise on business opportunities. This is an exciting challenge for the manufacturers but a complex execution process that requires careful planning. Industry experts unite to untie the knots of hurdles to scale up manufacturing.

Envision receiving an order twice the capacity of your production. This inquiry is a step ahead for growing the business. With the existing resources, a manufacturer can ensure that the system runs at its double capacity, be it the machines or labour. The approach will suffice if the order is exactly double capacity and not an inch more. The manufacturers here need pre-vision planning for such a situation. With the Indian manufacturing sector poised to reach US$ 1 trillion by 2025-26, led by Gujarat, Maharashtra, and Tamil Nadu, fueled by investments in automobile, electronics, and textile industries, the market demand is notably on the rise. All the participants have an equal and better opportunity to increase their production capacity gradually to conquer the market of their realm.

Manufacturing practices

Increasing your manufacturing output requires coordinating your resources, processes, and systems to handle larger production volumes while maintaining quality and efficiency.

While discussing scalability from a manufacturer’s perspective, Uday Narang, Chairman of Anglian Omega Group and Omega Seiki Mobility, states that in manufacturing, we need to see that the culture supports the overall technology. We have noticed the emergence of many startups with technology that cannot achieve scalability. Technology cannot be purchased; it needs to be adopted, and buy-in from your entire team is necessary.

Challenges

Success is subjective; what suits one may not suit another. Dr. Nagahanumaiah, Director of Central Manufacturing Technology Institute, shares that if you look at MSMEs, the adaptability of the technology largely depends on the HR department, but they often need to absorb the technology. When MSMEs seek to integrate technology, their objectives differ. Consider a company operating in job shops, like ABB; their priorities are distinct. Meanwhile, an MSME shop worker would be keen on adopting industry-specific technology if it promises to enhance machining efficiency, even by a mere 10%, through digitisation options.

Surendra Lavate, Head of Business Development – Industries, B&R Industrial Automation Pvt. Ltd., says, “scalability is where we need to upgrade our assets to a new level to produce and serve customer demands. But businesses have brownfields already running. Integrating a new asset base will always be challenging, so how will you handle it? The base is to consider whether the new technology will increase areas of efficiency. Another challenge is to train the existing workforce on various technologies. Manufacturers have to see how they adapt to technology shift and whether they are in a position to manage.”

From the industry perspective of a practitioner, Ashok Agarwal, Vice President of Manufacturing at Jio Platforms Ltd., says that there are two aspects of manufacturing—demand and supply. We now have technologies available for both sides. Demand has four Cs: career, content, connectivity, and commerce.

The whole aspect has to make business sense to which every industry can relate. For example, a career in telecom might mean a distribution channel, content in telecom, or retail will lead to customer satisfaction. So the four C’s of the demand side need to be integrated with the four M’s of the supply side, which are man, machine, materials and methods. A flair of technology is available to merge these four C’s with the four M’s. All the challenges coincide with this formula, and so do the opportunities.

MSMEs

MSMEs need assessment to determine whether they are in the booming phase or if they are in the process of transitioning from 2.0 to 3.0. Dr Nagahanumaiah shares details about their collaboration with the ministry-funded programme. He shares how CMTI conducts webinars and interaction sessions with MSMEs regularly, and they have learnt that the users feel digitisation is a buzzword because only two things matter to them: Can I increase my productivity or the quality of my output? The solution is that MSMEs must evaluate the data acquisition, processing, digital trend mapping, mapping, and all the associated analyses.

Technology has become affordable. Various firms provide analytics and evaluate the credibility of data. Once you have identified your goal with technology, it is unnecessary to look into everything and adopt it. Decide on the objective and look at the case studies and solutions that work. During this process, maintenance and resources should be taken into account.

EV manufacturing boom

While discussing the means to scale up manufacturing, the electric vehicle (EV) industry is a prime topic as it has experienced rapid growth over the past decade. Narang shares that the rapid acceleration of the EV industry is due to factors such as an improving supply chain, efficient pricing of batteries and power trains, and the increasing scale of the market. The industry will grow, and the two-wheeler market is expected to grow by 80 percent by the end of the year. The commercial sector, which operates in one-tonne and three-tonne trucks, is expected to see no significant difference between the two types of vehicles in the coming years.

Scaling up depends on the pricing and the total cost of ownership. Manufacturers have to build products that save money for users. The total cost of ownership models work in production. In using technology, developers will have to invent multiple products where having better technology reduces the cost. Five years ago, EVs were not even present; now, we have huge demand and supply. On the same line, the issue of supply chain inventory will be mended. The way Rome was not built in a day, the scaling up of technology and its integration will also take time.

India is also working on hydrogen and many similar technologies while manufacturing EVs. But our nation moves forward with one question – How do I save money? In essence, the environment is good only as a conversation topic; to the core implementation, people turn a blind eye to it. As a strong advocate for sustainability, Mr Narang emphasises our responsibility to our nation and future generations to leave behind a greener and cleaner country. If neglected, we will encounter significant challenges, like Banglore’s water crisis and Delhi’s deteriorating air quality.

Upskilling the workforceThe change starts with people adopting technology, and they should be knowledgeable enough to understand it. Mr Lavate mentions that a change from the curriculum level is required. The number of deemed universities is rising, and colleges have the liberty to modify their curriculum. This can be done by collaborating with industry requirements. Many institutions like JAIN (Deemed-to-be University) have already adopted this model and collaborated with Google Cloud to equip their students with open web and cloud technologies. Punjab Engineering College collaborated with M/s Siemens and its partner M/s MTAB Technology to establish a Center of Excellence (CoE) at PEC. This centre is dedicated to engineering, product development and advanced manufacturing technologies.

Industry incentives are required for upskilling. There are incentives for R&D and CSRS, the same way we need investments for workforce enhancement and new technology deployment.

IoT sensors

There are opportunities to integrate IoT and sensors to scale manufacturing. Mr Agarwal shared that JIO platforms are an imperial example of the use of IoT. They have integrated IoT into uplifting the lives of farmers by incorporating sensors. They have made IoT sensors for the great orchards Nasik connected to their platform. The sensors monitor the loss of vegetation and the reason for promoting it. The monitoring has led to immense productivity improvement. Sensors have been used for health management, leading to a decrease in loss of life.

IoT plays a role in EV manufacturing by answering questions about how to develop probable battery systems and connect them to IoT platforms. This incorporation will also provide users with a lot of transparency.

Scaling up manufacturing relies on adaptability and flexibility. Flexibility refers to the ability of a machine to handle various products. In contrast, adaptability refers to the ability of a machine or line to adapt to changes in product, shape, or packaging. This adaptability is essential for ensuring the machine is ready for current and future use. However, expanding the machine and product while maintaining the current installation base is another aspect of adaptability. Scaling is a comprehensive strategy that requires manufacturers to adapt to sustain themselves and elevate their business to the next level.

————————————————————————————————————

Ashok Agarwal, Vice President – Manufacturing, Jio Platforms Ltd.

IoT sensors and platforms lead to productivity improvements across healthcare, agriculture, and automotive sectors, ultimately growing the manufacturing sector.

Dr. Nagahanumaiah, Director, Central Manufacturing Technology Institute.

Adaptability and flexibility are crucial in manufacturing; machines must handle various products and adapt to changes, ensuring productivity and readiness for current and future needs.

Uday Narang, Chairman, Anglian Omega Group & Omega Seiki Mobility

Adapting to the culture is crucial in the manufacturing industry, and the entire team needs to be onboard for scalability and success.

Mr. Surendra Lavate, Head of Business Development – Industries, B&R Industrial Automation Pvt. Ltd. (A member of the ABB Group)

Integrating existing assets with new technologies will elevate manufacturing production efficiency, while continuous education and incentives will prepare the workforce for technology deployment.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.