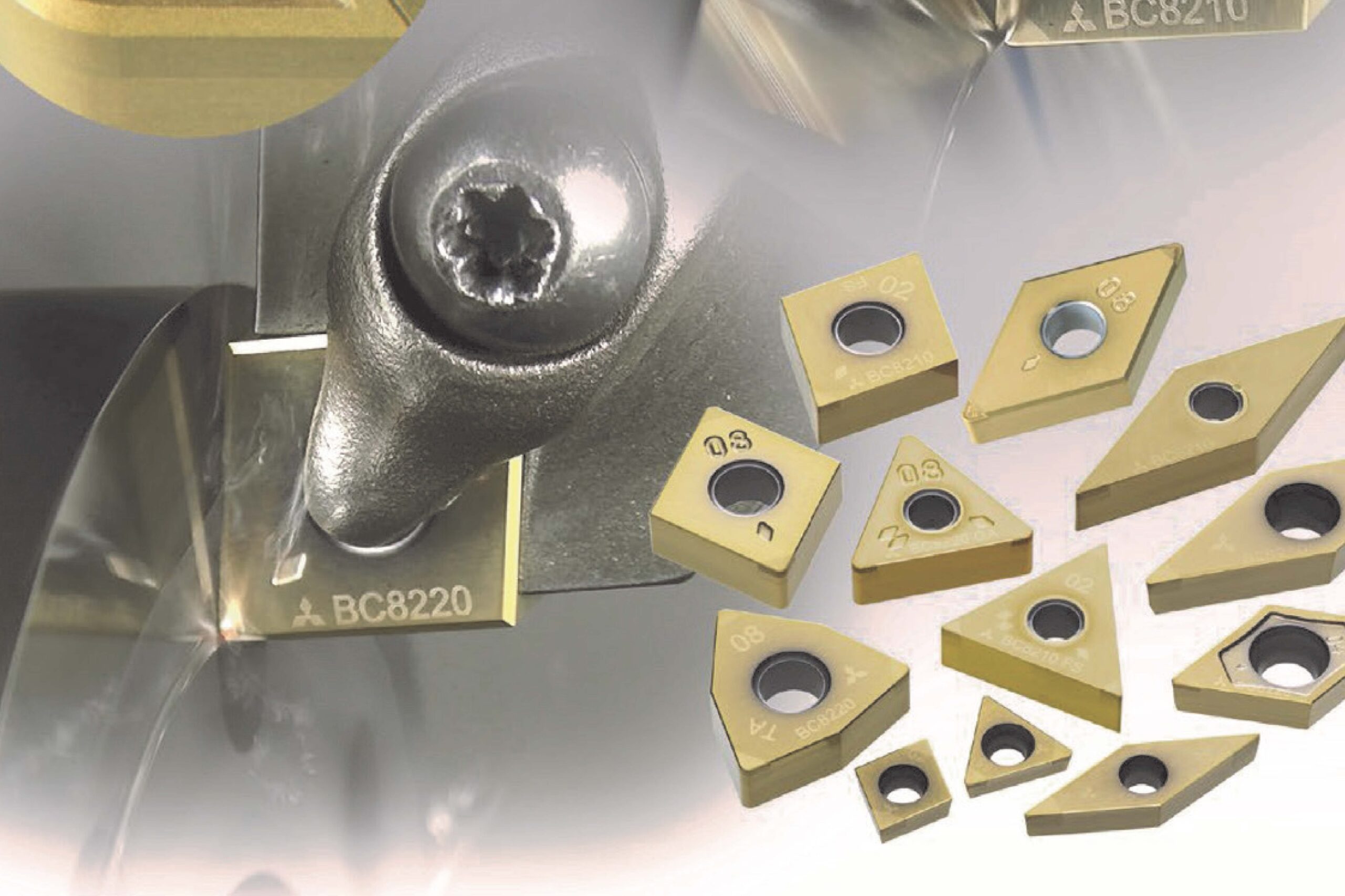

Advanced CBN grades for efficient turning of hardened steel

By Staff Report October 15, 2025 5:14 pm IST

Turning hardened steel demands advanced tooling to resist extreme wear and heat. The BC8200 Series CBN grades deliver stability, efficiency, and extended tool life through innovative coatings, binders, and chip control technologies.

CBN Grades for Turning Hardened Steel

The machining of hardened steels requires advanced cutting tools that can withstand high temperatures, heavy loads, and demanding applications. The BC8200 Series is coated with CBN (Cubic Boron Nitride) grades and designed specifically for modern turning methods. These grades combine innovative coatings, optimised binders, and reliable chip control technologies to deliver stable performance, improved efficiency, and extended tool life.

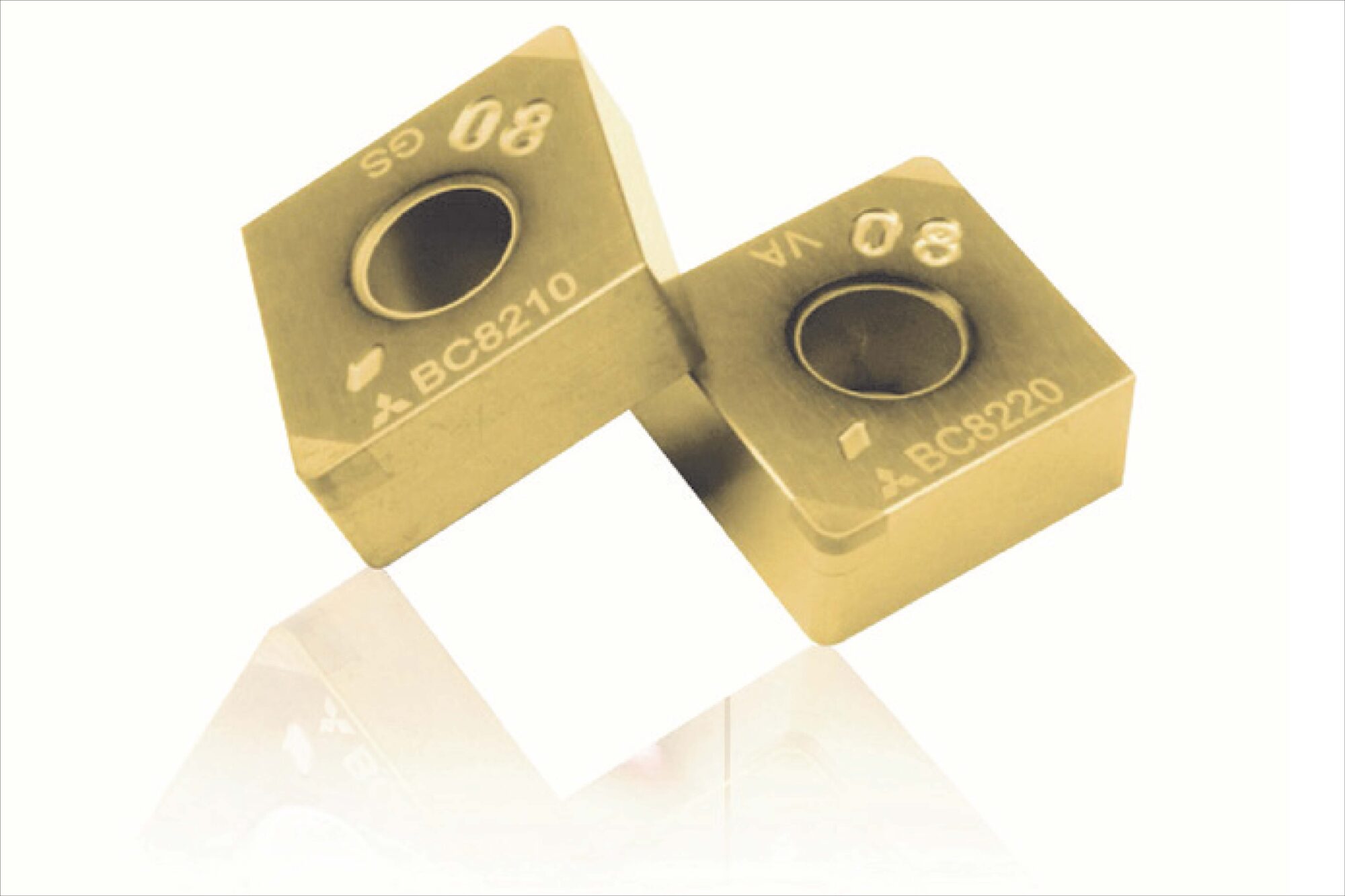

BC8210 – For Continuous and Light Interrupted Cutting

The BC8210 grade is engineered for continuous cutting and light interrupted cutting operations. It delivers outstanding tool life, even at high-speed machining conditions, while maintaining excellent resistance to chipping, flank wear, and crater wear. This makes BC8210 highly suitable for stable machining processes under demanding cutting conditions.

BC8220 – For General Applications

The BC8220 grade has been developed for a wide range of applications, from continuous cutting to heavy interrupted cutting. It demonstrates impressive tool life across different cutting conditions due to the combination of a newly designed CBN base material and an advanced coating. With excellent crater wear and fracture resistance, BC8220 delivers stable performance and extends tool life in diverse machining environments.

Key features of the BC8200 series BC8210 Features

- Incorporates a newly developed AlCrSiN-base coating that absorbs impacts and a TiAlSiN-base coating that offers high wear resistance, ensuring stable performance in both continuous and light-interrupted cutting.

- Equipped with ultra-micro-particles and heat-resistant binder technology, the CBN substrate suppresses chipping and crater wear, which directly contributes to longer tool life.

- The optimised substrate technology, combined with the ultra-micro-particle binder, prevents linear crack fracturing, enhancing reliability.

BC8220 Features

- Utilises a TiAlN-based coating structure that suppresses crack growth within the coating and reduces edge chipping, resulting in stable cutting performance across a wide variety of applications.

- The newly developed heat-resistant binder improves wear resistance by reducing deterioration, effectively suppressing crater wear, chipping, and fracturing.

Insert features for improved machining, Chip Breaker Technology

To enhance chip control and machining stability, the BC8200 series offers a versatile range of chip breakers:

- BR Breaker (BC8220): Designed for higher depths of cut, it reduces the number of passes required while improving chip control. Its rake angle and multi-stage breaker wall support a wide range of applications.

- BM Breaker (BC8220): Ensures effective chip control during medium-depth cutting operations (0.3–0.8 mm).

- BF Breaker (BC8210, BC8220): Provides excellent chip control for finishing operations at depths of 0.3 mm or less.

Wiper Insert features

Wiper inserts further enhance machining performance by combining high feed rates with improved efficiency and durability.

- Improved Surface Finish: Even with higher feed rates compared to conventional chip breakers, the wiper insert delivers a superior surface finish.

- Enhanced Efficiency: Shorter machining times allow for roughing and finishing operations to be combined, streamlining production.

- Extended Tool Life: At high feed conditions, cutting time per component decreases, enabling more parts to be machined per insert. The high feed rate also reduces rubbing, which delays tool wear.

- Better Chip Control: Thicker chips produced at high feed rates are easier to break, providing stable chip control.

For more details, please referwww.mitsubishicarbide.com

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.