Increasing Laser Cutting performance with Reckon & Romax

By OEM Update Editorial September 14, 2023 3:02 pm IST

Planetary gearboxes are prescribed in 2 different situations: as a one-to-one replacement of a competitor product, or in a new customer development. Recommending an alternative product in an existing application is an easy task, as our engineers know that their design is safe.

Reckon gearboxes can replace gearboxes of similar size and interface at no risk. In the second case, when customers design new systems, it is our responsibility to recommend a reliable solution that matches all specifications. From a customer perspective, determining the appropriate gearbox size using standard catalogs is becoming viewed as unreliable and fraught with risk. More and more engineers are beginning to question the accuracy of the values provided in datasheets. Personally, we hold the belief that the recent uptick in reported product performance by certain suppliers is puzzling and cannot be attributed solely to improvements in design, materials, treatments, or lubricants.

Customers now expect that manufacturers proceed to argued recommendation, based on solid, reliable data.

Explaining the discrepancy between our torque ratings and those of our competitors to our customers is a challenging task. This is because when it comes to assessing gearbox torque ratings, there can be significant variation. For instance, ten different gear designers may assign ten different torque ratings to the same gearbox. These variations are influenced by factors such as the specific norms or norm versions they follow, the safety margins they choose to incorporate, and the scenarios they consider in their calculations, such as speed, heat, and the location of shaft loads.

To address this question effectively, one would need to understand the methodology used to calculate the torque ratings, which is often not provided in catalogs. It’s essential to recognize that the gearbox with the highest torque rating isn’t necessarily the best choice. In fact, it may indicate that safety margins have been reduced to present more favorable data, which we consider to be potentially misleading.

In our industry, when datasheet ratings are genuinely provided, they often rely on standards that assume an ideal scenario where every component is precisely positioned and manufactured. In this idealized scenario, the performance of each individual part is not influenced by the interactions with other components both inside and outside the gearbox. It also assumes that any radial loads on the shaft only affect the gearbox’s output bearings or the shaft itself. However, the reality in practical applications is quite different.

Romax Enduro functions

As it is able to take all these parameters into account, Romax Enduro estimates real-life conditions more accurately than any other software we used before. We can show how our products behave in any application.

While natively integrating most calculation norms including the latest updates of the ISO 6336-2:2006 for gear calculation and the TS 16281:2008 for bearing calculation, English company Romax goes further and works with the most respected experts around the world to develop their own additional algorithms. Functions now available in Romax Enduro enable increasing design reliability and estimating very precisely the life of a complete gearbox, taking all aspects of real-life conditions into account. Using Romax, we can now estimate the life of each gearbox in our customers application, component by component, taking into account the impact on a component on the other, and, more importantly, considering your output element as a part or the system.

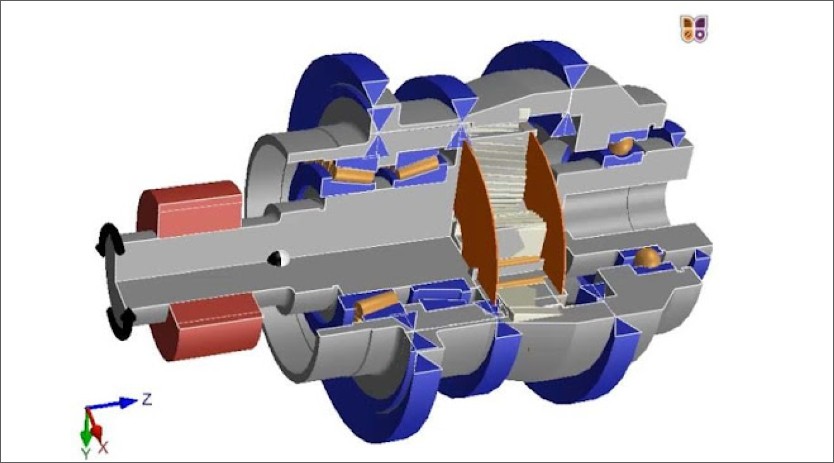

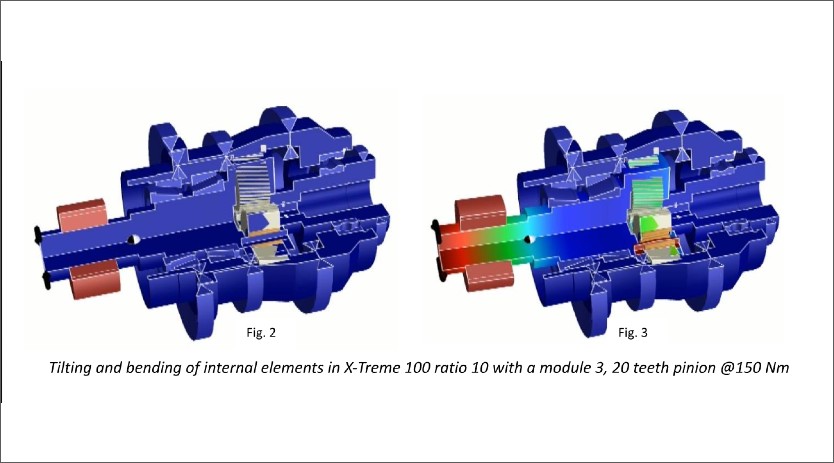

The following phenomenon is typical: in a rack and pinion transmission, the combined loads generated by the helical pinion are applied to the output shaft, they bend it, tilt it around the output bearings, twistthe planet carrier, which compresses the ring gear onto the gears, the needles against the planets, the planets against the sun gear and finally applies a radial load on the customer motor shaft! As a result the sun gear suffers more than what the basic norms can estimate (basic algorithms will only give L10h results) and becomes the weak element in the system. Romax Enduro can tell us the damage to each of these elements!The result of such calculation is obviously conservative when compared with standard datasheet ratings: in such or such application or working conditions, the same gearbox can be rated a certain torque value or only half of this value; but it is a fact that shafts, bearings, planet carriers, gears, needles, axles; all have their own stiffness. Who would prefer trusting catalog values that do not consider such a phenomenon?

Using Romax Enduro consequently makes our recommendations precise and professional: we now can tell you the difference in any internal element lifetime if you use a 25 teeth pinion rather than a 20 teeth pinion, as the resulting additional shaft torsion, flexion and tilt will reduce the size of the zone where the planets are transferred power from the sun gear, or transfer this power to the ring gear (this factor called the Khβ is clearly displayed in the results). Our engineers can show you that a 160 Nm gearbox is only a 120 Nm gearbox if you install a spiral bevel gear on its output shaft, because the radial and axial load generated by the bevel gear set will compress and deform the output bearings and tilt all the components inside above this torque. We can tell you that adding 2 teeth to your pinion and increasing the ratio slightly can sometimes increase, sometimes decrease the overall life, depending on the initial ratio.

Because even the greatest products cannot perform if poorly sized, we are ready to give our customers the perfect recommendation so their application achieves the longest lifetime and the best performance.

Expertise shared by: Martin MIJNO, CEO and founder of Reckon Drives International SAS, France.

For more information and assistance on improving your reliability, contact us at:

Amcats Pvt. Ltd., Turbhe, Navi Mumbai 400705.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.