The AI Hub@EMO2025 is a testing ground for the future of production

By Staff Report September 23, 2025 12:40 pm IST

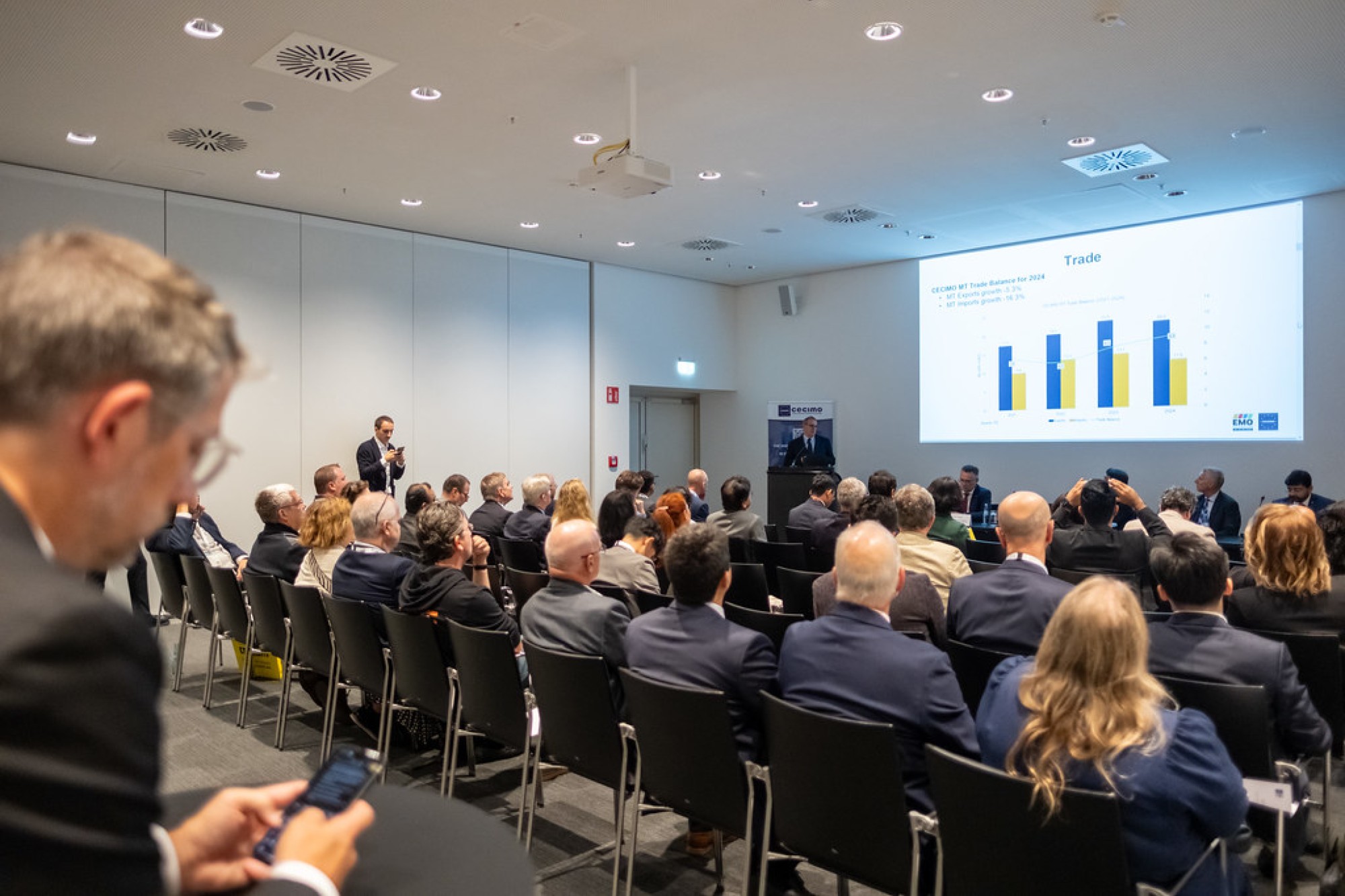

The AI Hub@EMO 2025 in Hall 6, Stand A22, is the central meeting point for all EMO visitors who want to experience, understand and use AI in production. With interactive demonstrators, the AI-supported chatbot Emil and real-life application examples, the hub offers guidance and allows visitors to get a better understanding of what AI actually is. Targeted at trade visitors, developers and decision-makers, the AI Hub@EMO 2025 invites everyone to discover the potential of AI for their own production and to talk to experts about it.

Artificial intelligence (AI) has long since made the transition from research into real-life industrial applications. It is fundamentally changing production, from quality assurance and process optimisation through to predictive maintenance. “In view of the great attention that AI is currently receiving in the business sector, the EMO naturally has to address its current state of development,” says Dr Alexander Broos, Director Research and Technology at the VDW (German Machine Tool Builders’ Association), organiser of the AI Hub@EMO2025. “That’s why we have brought some of the real-life applications that are already being used in production technology to the trade fair so visitors can see the applications for themselves.”

Emil: AI-supported guidance for trade fair visits

A central element of the AI Hub@EMO2025 is the chatbot Emil, developed on behalf of the VDW by aiXbrain GmbH from Aachen in Germany, in collaboration with the Machine Tool Laboratory (WZL) of RWTH Aachen University. Emil will help trade fair visitors to quickly find information relating to AI. Visitors can chat with him, ask him about AI solutions for the metalworking sector, enquire about exhibitors who offer these kinds of solutions, ask him to point out stands on the map of the hall and much more. “The ability to interact with an AI solution is an essential part of any stand that is focused on AI,” emphasises Broos.

The AI-supported chatbot is based on a Large Language Model (LLM) and was trained on the digital exhibitor profiles from the directory of exhibitors. Visitors can interact with it directly at the terminal in the AI Hub @EMO2025 in German and English. “For Emil, we were able to draw on our experience in implementing machine-specific AI solutions,” explains Dr Simon Görtzen, CTO and co-founder of aiXbrain. “It goes without saying that a public application in the context of such a large trade fair poses particular challenges in terms of training and quality assurance, but as a team we were able to overcome these challenges effectively and efficiently.”

ProKI: Research meets industrial application

Demonstrators from the ProKI research network will be showing how AI is used in production. This association of eight German university institutes supports small and medium-sized enterprises (SMEs) with the introduction of AI in production. The project, originally funded by the Federal Ministry of Education and Research (BMBF), has been supported by the WGP (German Academic Association for Production Technology) since 2025. “AI has now been established in society for quite some time. What we need to do now is to harness its specific potential for production technology. In this context, the AI Hub@EMO2025 creates a crucial link between university research and industrial application,” explains Prof. Jürgen Fleischer, Director of Machines, Equipment and Process Automation at the Institute of Production Science (wbk) at the Karlsruhe Institute of Technology (KIT), and one of the spokespersons for ProKI in the WGP.

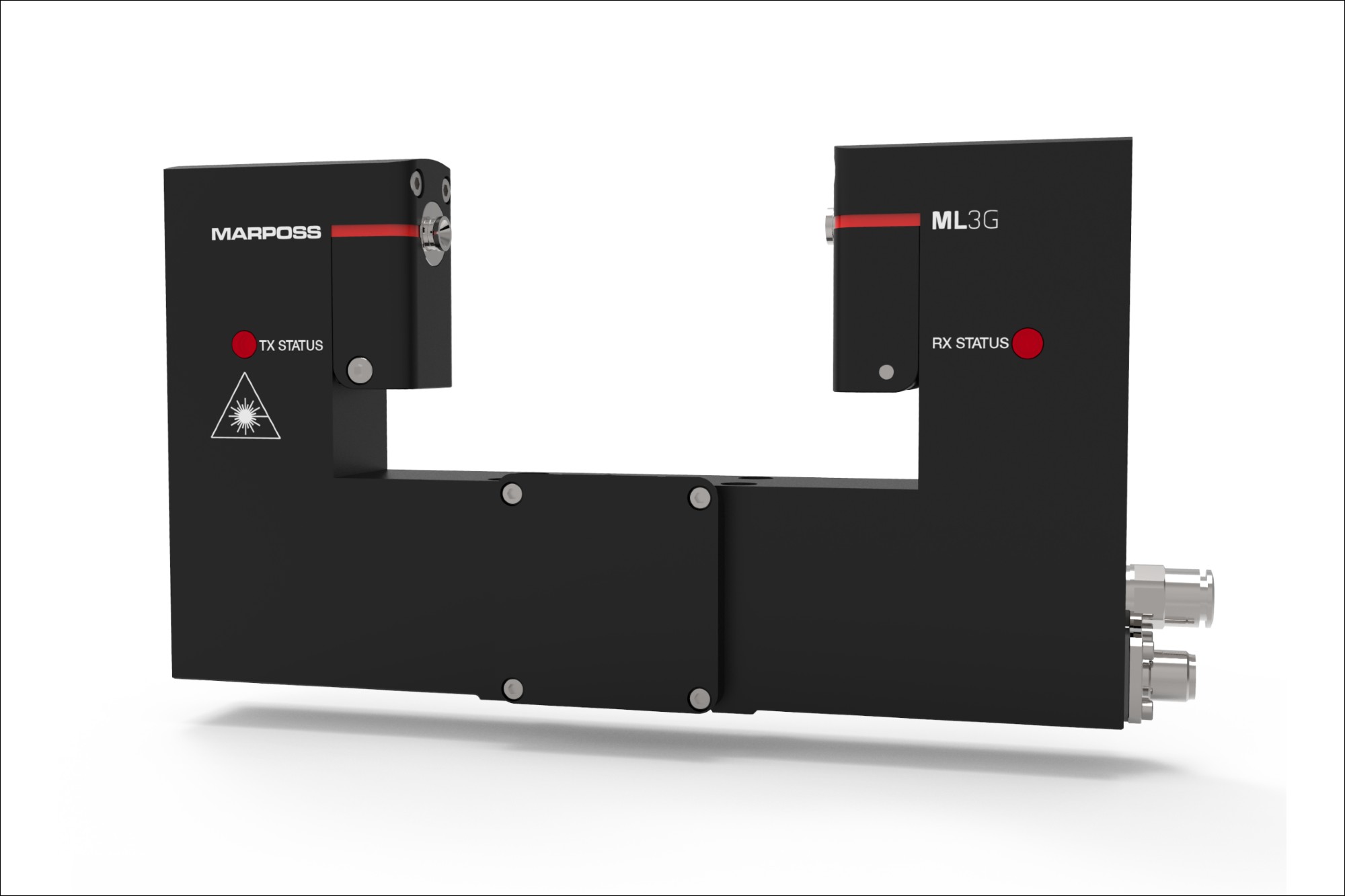

Exhibits at the AI Hub@EMO 2025 show the immediate benefits. The Berlin-based WGP researchers from the Institute of Machine Tools and Factory Management (IWF) will be demonstrating image segmentation of discharge craters from spark erosion processes using the Segment-Anything-Model (SAM). This approach offers great potential for quality assurance and automation – without prior training.

The team from the Institute of Production Technology (WBK) in Karlsruhe is bringing two exhibits to the EMO 2025: An image-based gearwheel identifier for quality inspection and the KGT-Cam for monitoring the condition of ball screw drives. SMEs in particular were involved in the development of the demonstrators.

A research group from the Machine Tool Laboratory (WZL) at RWTH Aachen University will be demonstrating a solution for through-hole technology, whereby synthetic image data trains neural networks for the precise recognition of components, forming a basis for flexible automation with high numbers of component variants.

These examples clearly illustrate the fact that, while image processing is already firmly established in quality assurance applications, AI considerably expands the possibilities – from inline inspections and adaptive process control through to condition-based maintenance.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.