Cataloguing energy efficient gears and motors

By OEM Update Editorial February 11, 2019 3:24 pm IST

In this story, experts share their views on what needs to be done for power loss reduction in a gearbox and to optimise gearbox efficiency in industrial applications.

As per conventional business practice, motor and gear efficiency form a part of deliverables and specified in the SOP of delivery catalogues. But, fact of the matter is that total system efficiency (motor and gearbox) is not correctly arrived at as per specifications, as efficiency depends on gearbox loading – heavy v/s normal. Efficiency tolerances or the difference in efficiencies between a heavily-loaded gearbox and one running under normal loads determines the efficiency chart in a given situation. As such, usual specs in print line may not match with realistic situation.

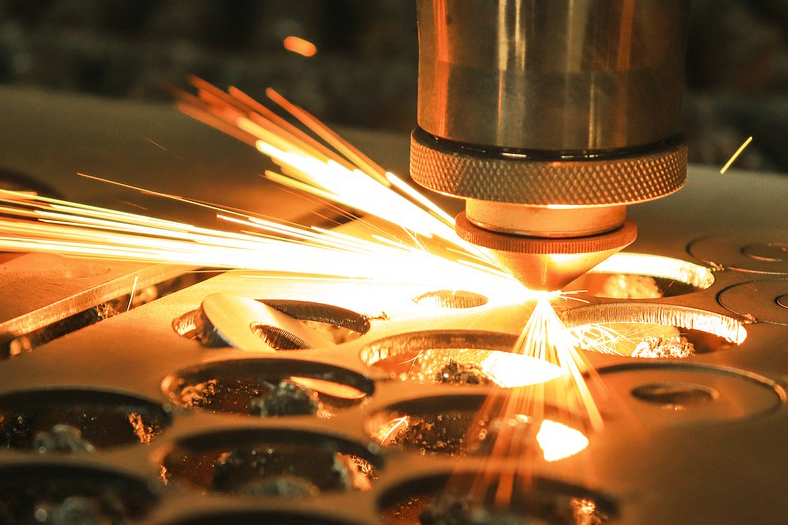

Optimising gearbox efficiency in industrial applications

Nishit Behera, Executive Director – Business Development & Strategy, RSB Transmissions (I) Ltd, states “Power loss in a gearbox is attributed mainly to friction, resulting in heat generation. While heat generation is not an issue with smaller gearboxes as it is minimal within the tolerance limit, in case of larger ones, it is more. This is compensated by use of oil coolers and pumps to keep the efficiency at a stipulated level. Efficiency also depends on the quality of gearing, the number of tooth engagements and the torque load to reduce frictional heat.”

Overall system efficiencies depend on the efficiency of the motor and gearbox together. At low ratios, motors are more heavily loaded than the gearboxes. At higher gearbox ratios, motor and gearbox efficiencies follow similar pattern as the gearbox sees more of the load than does the motor. This leads to peak efficiencies in both gearbox and motor. To use the least amount of power and obtain gearbox efficiency at its peak, it’s critical to match the motor, gearbox, and load closely to get the best system efficiencies.

According to Abhishek Dhupar, Program Manager, Motors, International Copper Association India (ICA India), “Gearbox is actually more of a mechanical device. There are two types of gearboxes: Worm and helical gearbox. Helical gearbox is more efficient than a worm gearbox. So, to improve the loss reduction, we should go for helical gearbox. Let’s say there’s a gearbox with a standard efficiency motor. You can replace it with an IE3 efficiency motor so that your gearbox becomes more efficient. By using a latest technology motor such as Permanent Magnet Synchronous Motor (PMSM) or a copper rotor motor, you can reduce the size or length and weight of geared motor.”

Energy efficient motors remains low in India

Motors traditionally converts electrical energy into mechanical energy by the interaction between magnetic fields set up in the stator and rotor windings. Industrial motors available in India are broadly classified as: induction motors and direct current motors. All motor types have the same four operating components, stator (stationary windings) and rotor (rotating windings), bearings and frame.

According to Behera, energy losses in Indian motors are characterised byfixed losses and variable losses, under the umbrella of intrinsic losses. Fixed losses consist of magnetic core losses and friction or windage losses. Variable losses consist of resistance losses in the stator, rotor and miscellaneous stray losses such as resistance to current flow in the stator and rotor result in heat generation that is proportional to the resistance of the material. These losses are more due to varied economic factors, but to keep the losses to minimal, the technological up-gradation will be warranted after field study.

Performance of motors in India are, by and large, affected by the quality of input power from public utilities, that is the actual volts and frequency available at motor terminals vis-à-vis rated values as well as voltage/ frequency variations and voltage imbalance. Motors in India need to comply with higher in-built tolerance limits to take care of larger fluctuations of in-put power in of public utilities in India as such wide fluctuations have shown detrimental impacts on motor performance and consequently on the industrial output.

Ambient conditions prevailing at different locations have a detrimental impact on motor performance.Nishit Behera, Executive Director – Business Development & Strategy, RSB Transmissions (I) Ltd

The penetration of energy efficient motors was low because there was no minimum efficiency standard in place.

Abhishek Dhupar, Program Manager, Motors, ICA India

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.