Revalyu eliminates virgin PET with chemical recycling technology

By Staff Report June 18, 2025 5:06 pm IST

To minimise environmental impact during the conversion of used Polyethylene terephthalate bottles (PET) into high-quality recycled polyethene terephthalate (rPET), revalyu’s chemical recycling process is designed to be environment-friendly compared to traditional methods. The entire process is fully automated and engineered to achieve high resource efficiency. Dr Vivek Tandon, Founder of revalyu Group, shares detailed recycling processes from PET waste collection to the final product.

Can you walk us through revalyu’s recycling process step by step, from PET waste collection to the final product?

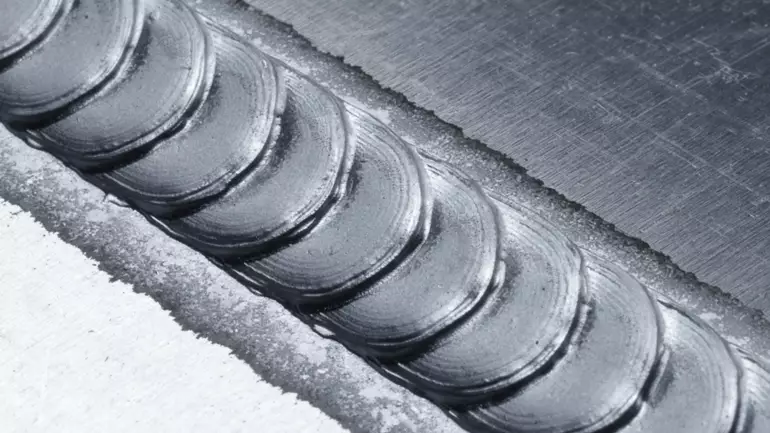

We initiate our recycling process by collecting used PET bottles, which are then thoroughly cleaned and sorted, then bottles undergo our patented chemical recycling process, glycolysis, which breaks down PET into its core monomers using mono ethylene glycol (MEG).

This depolymerisation process produces high-purity esters, which are then reprocessed into rPET chips. These chips are either sold directly or further processed into 100% recycled, virgin-quality draw-textured yarn (DTY), which is ideal for textile applications and used to remake bottles and polyester packaging materials.

The entire process is highly efficient and sustainable, achieving virgin-grade output with significantly reduced environmental impact. At our Nashik plant, we recycle over 35 million bottles daily, converting them into high-performance, eco-friendly materials for the global textile and packaging industries.

What types of recycling machinery and technologies does revalyu use in its operations?

We use glycolysis technology at the Nashik facility to efficiently depolymerise post-consumer PET bottles into their core monomers. Our key technologies and machinery include potent glycolysis reactors, advanced purification units, polymerisation systems, draw-texturing machinery, and solid-state polymerisers. These processes break down PET into monomers, convert purified esters back into PET chips, and create high-performance recycled polyester filament yarn (DTY). The polymer’s intrinsic viscosity is increased using solid-state polymerisers for PET bottle production.

Our integrated recycling plants support scalable, high-efficiency, and low-emission operations while maintaining consistent product quality.

How does revalyu ensure sustainability at each stage of the recycling process?

Sustainability is integral to our recycling process, starting from the collection of post-consumer PET bottles, which divert plastic waste from landfills. The process eliminates the need for virgin raw materials PTA and MEG by using existing PET waste as feedstock, thus avoiding fossil fuel extraction. Furthermore, our facility employs closed-loop systems to recycle water internally and leverages shared infrastructure across its three recycling plants to reduce emissions and resource use. Every stage of the process is designed to align with circular economy principles high-performance, sustainable products.What measures are taken to minimise environmental impact during the conversion of used PET bottles into high-quality rPET?

Our chemical recycling process is designed to be environment-friendly compared to traditional methods. It uses 91% less energy and 95% less water than conventional PET manufacturing. The entire process—from depolymerisation to repolymerisation—is fully automated and engineered to achieve high resource efficiency. Additionally, rainwater harvesting and renewable energy initiatives are in place, and revalyu aims to transition fully to biomass and renewable sources for heat energy by 2025. The plant operates as a zero-liquid discharge facility, with all water treated and reused onsite, ensuring no contaminated water is released into the environment.

How do you monitor and manage energy and water consumption throughout the recycling process?

Energy and water usage are continuously monitored through automated systems integrated into the plant’s operations. All water used in the recycling process is collected, treated using a state-of-the-art RO plant, and then reused, ensuring 100% water recycling. We also implement energy-efficient technologies and have committed to a CO₂-neutral roadmap. This includes the planned transition to renewable and biomass-based heat sources by the end of 2025. These practices are aimed at reducing resource consumption and minimising greenhouse gas emissions.

Does revalyu have any certifications or third-party validations that support its sustainable practices?

We are a global recycling company that is a signatory to the United Nations’ Science Based Targets initiative (SBTi). We have already reduced our carbon footprint by 50%, using 2016 as the baseline year. We comply with stringent environmental standards and incorporate third-party validations as part of our sustainability roadmap. These certifications reinforce our commitment to delivering one of the lowest carbon footprint polyesters in the world, further solidifying its role as a responsible and sustainable industry leader.

Over a decade, we’ve been producing detailed Life Cycle Analysis (LCA) reports using third-party experts and collaborating with our customers to enhance our processes.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.