CNC precision rises where small hands build

By Staff Report April 30, 2025 7:01 pm IST

The vision to create India as a viable manufacturing centre compared to others requires great effort and strategy. India is lauded with MSME players in all sectors. India’s industrial landscape is lauded for its vibrant ecosystem of MSMEs, which is spread across various manufacturing domains. In this special feature, OEM Update shines the spotlight on CNC machines and the role of MSMEs in this segment. We delve into the challenges these enterprises face and explore practical solutions to overcome these barriers, guided by insights and perspectives from industry experts, where each expert covers a vital element of CNC manufacturing.

Innovation is reshaping industries across the globe, and Indian manufacturing is riding this wave with remarkable momentum. India is home to over 73 million MSMEs, employing more than 120 million individuals. These enterprises contribute nearly 30% to the national GDP, accounting for over 35% of the country’s manufacturing output. MSMEs are thus central to inclusive industrial growth in India.

Large players have long embraced CNC technologies, but the MSMEs are now making bold moves. CNC machines are equally vital for small and medium enterprises seeking to automate production, enhance precision, boost repeatability, and reduce costs. However, most small-scale manufacturers face numerous challenges, ranging from financial constraints to inadequate skilling. Industry experts in CNC machinery shared insights on how MSMEs can make a mark with CNC technologies and offered practical tips to overcome these common challenges.

——————————————————————————————————-

AROOP Sarkar, Industrialisation Engineer, John Cockerill

New Innovations

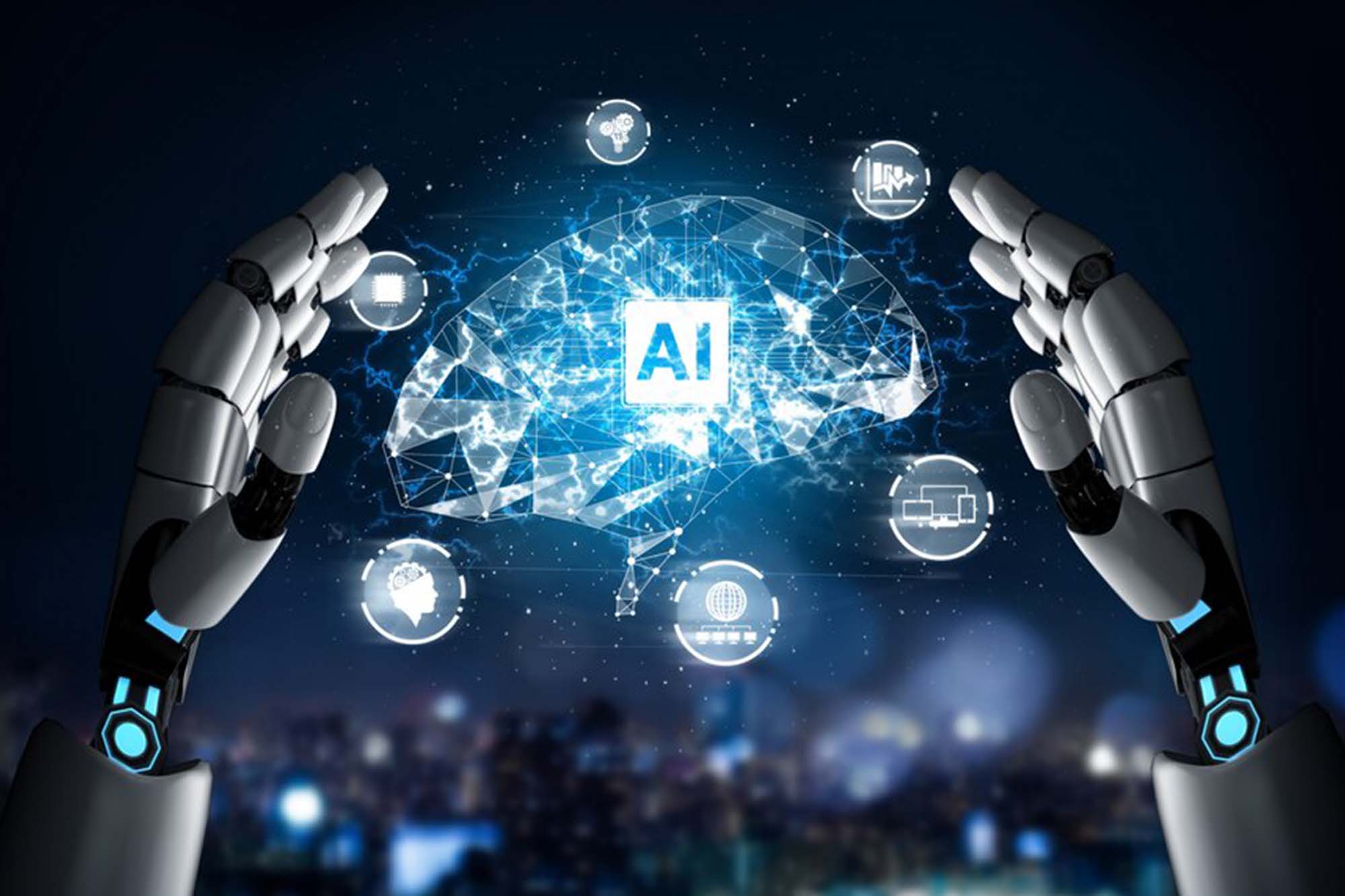

AI-driven predictive maintenance in CNC (Computer Numerical Control) machines is rising. As industries pivot from reactive fixes to proactive strategies, AI helps maintain, operate, and optimise CNC machines for automotive, aerospace, and precision engineering.

AI-enabled CNC machines use vibration, temperature, and sound sensor data to predict potential failures before they occur. This minimises unplanned downtime, cuts maintenance costs, and improves equipment life. AI provides real-time, condition-based servicing instead of fixed maintenance intervals, enhancing efficiency and effectiveness in the maintenance process.

With IoT integration, small and midsized manufacturers in Tier-2 and Tier-3 cities can access advanced diagnostics remotely—an essential shift post-COVID. For example, companies in Maharashtra and Tamil Nadu are piloting AI-integrated solutions like Bosch’s i4.0 India to modernise older CNC systems.

Tomorrow’s CNC machines will do more than cut and mill—they’ll adapt and optimise themselves. AI-powered CAM intelligent software is automating toolpath generation for precision and efficiency.

Self-learning machines will improve with every job, learning from previous runs to deliver higher quality. The integration of edge and cloud analytics allows real-time decision-making at the machine level, enabling long-term improvements through cloud-based insights.

The AI vision system automates on-the-fly quality checks, thereby reducing defects and streamlining production processes.

As big players go digital, India’s MSMEs can stay competitive by being agile, collaborative, and tech-savvy. Collaborative clusters are established to share advanced machinery and inspection tools with nearby SMEs through alliances or government programs like MSME SAMARTH.

Lean Automation involves retrofitting legacy CNCs with affordable sensors or cloud platforms for immediate ROI. Government support can be provided through schemes like CLCSS, ZED, and NITI Aayog’s AI framework for financial and technical assistance and partners with NSDC or IIT-Madras programs to train workers in digital CNC operations.

————————————————————————————————–

Apurb Kumar Nayak, Industrial Automation & Robotics Faculty, Tata Indian Institute of Skills

Financing Challenges

For SMEs, adopting CNC machines requires strategic financing—whether through leasing, tapping into government subsidies like MSME schemes, or collaborative shared-access models—to mitigate the upfront costs. Achieving ROI hinges on operator training to minimise errors, consistent preventive maintenance to extend machine lifespan, and optimised workflows through batch production, waste reduction, and data analytics.

I always recommend starting with a single machine—prove its profitability first, then scale up gradually. As a CNC trainer at TATA Indian Institute of Skills, I work closely with SMEs to design training programs beyond machine operation. We focus on CNC, maintenance, and lean practices, ensuring machinery becomes profitable.

Indian SMEs face challenges in adopting advanced CNC machines due to high capital costs, limited technical expertise, and apprehensions about operational disruptions. Many of these lack skilled operators, which leads to underutilisation and maintenance inefficiencies.

Bridging this gap requires a dual strategy. SMEs can collaborate with training institutes to develop customised upskilling programs focusing on advanced manufacturing, precision machining, and preventive maintenance. Concurrently, exploring financing models like leasing or government subsidies can mitigate financial barriers.

———————————————

Sanjib Chakraborty, Managing Director, Hurco India Pvt., Ltd.

Collaboration of Large Players and MSMEs

Innovations in CNC machines are now focused on eco-friendly solutions, high-speed machining, improved software and digital technologies. IoT technology and advanced sensors enhance machine efficiency, while the rise of additive manufacturing is opening new avenues. Automation and AI-powered machine monitoring are streamlining operations and ensuring predictive maintenance.

Small-scale manufacturers can sustain themselves in an ecosystem dominated by large-scale industries through strategic partnerships and collaborations, continuous skill development, and securing ISO certification to access new markets and build trust. Innovating new designs and prototyping, establishing a strong digital marketing and online presence, and using cost-effective NC machines to boost productivity are essential. Their agility in decision-making and ability to build strong client relationships give them a competitive edge.

Encouragement for local and foreign firms to set up operations in India, along with R&D support from institutions like CMTI, is driving innovation. Skill development programs, technology transfers with global CNC leaders like BFW, Jyoti, and LMW, and dedicated support for MSMEs are also pivotal to this effort.

—————————————————————————————————

Mohammad Irfan, CNC Expert, Saudi Mechanical Industries

Growth of small-scale manufacturers

The most important thing that MSMEs need to accomplish is make to the delivery on time. Small manufacturers must also pay close attention to quality. By consistently focusing on these two factors—timely delivery and product quality—they can grow steadily, earn customer trust, and reach the heights of success in a competitive market.

All the CNC machine companies have made good progress so far. Innovations like Automatic offset reading, automatic material diameter calculation systems, and Automatic program generating systems are expected. Such advancements will benefit the industry by saving time, reducing manual errors, and improving overall efficiency in machining operations. If some such innovations happen, then the industry will get many benefits.

——————————————-

Abhishek Suchak, Scientist, Central Manufacturing Technology Institute

Return on Investment (ROI)

One of the primary challenges in the Indian market in adopting advanced CNC machines is significant investment and skilled manpower, often necessitating substantial upfront capital. These costs can be prohibitive, specifically for small and medium-sized enterprises.

The Indian market heavily relies on imported machine tools. A stronger push towards the ‘Make in India’ movement will generate great opportunities for domestic machine tool companies, which can provide better machines with robust build quality and better accuracy.

Accessing funds through various avenues like government subsidies and bank loans is simpler than ever. Individuals and businesses should proactively seek information about relevant funding schemes by central and state governments. Small and medium-sized enterprises (SMEs) can benefit from numerous tax advantages. Bank loans provide another readily available means of securing capital.

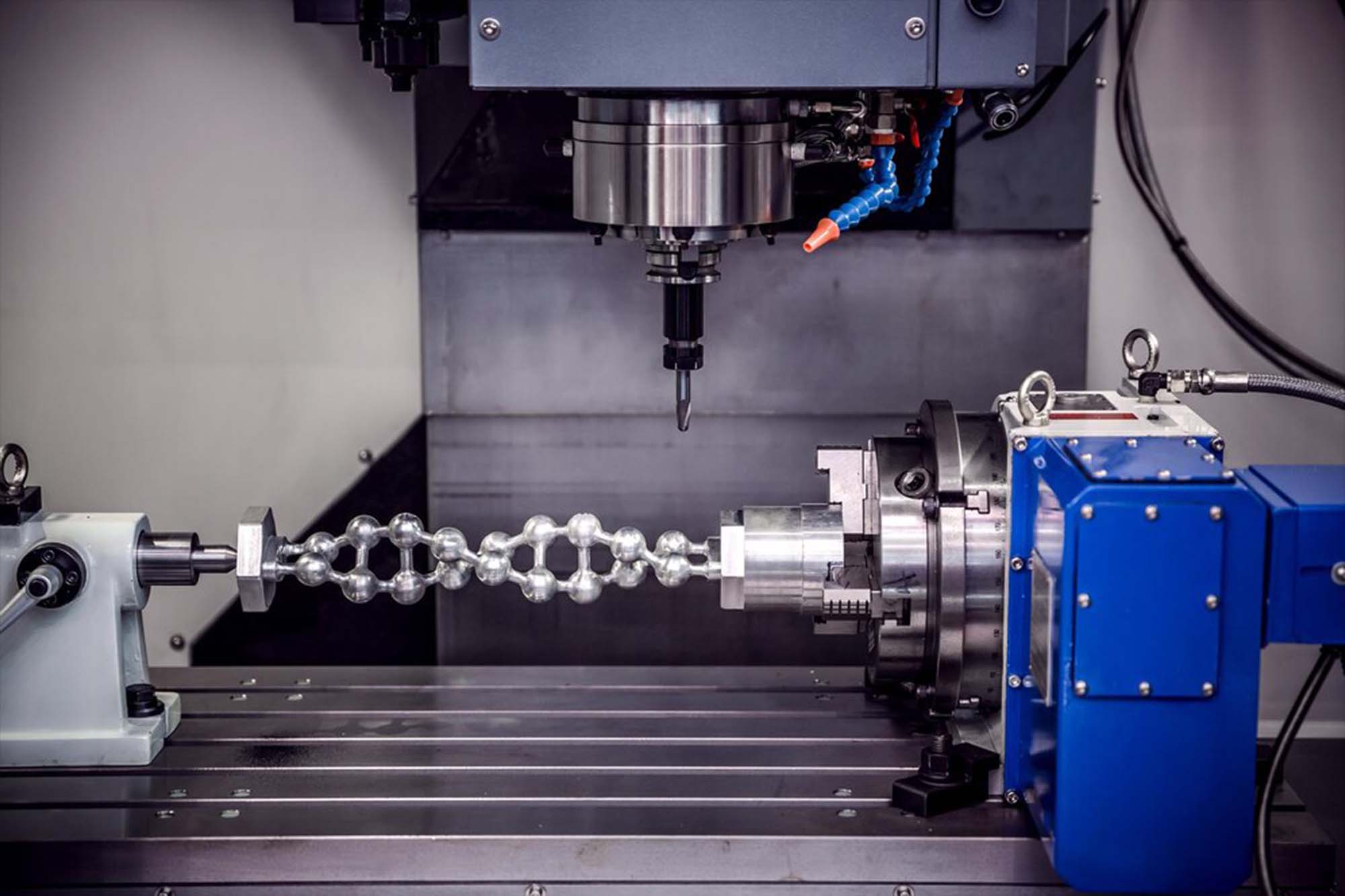

Achieving a better ROI is closely linked to a machine’s operational costs, which are directly influenced by factors such as material selection, tool selection, machine maintenance, and the availability of skilled manpower.

Choosing the right material for existing machines or selecting machinery that aligns with the nature of the work and raw materials is crucial. This ensures that machines operate at their optimal efficiency. Furthermore, the selection of tools plays a vital role in optimising the machine’s cycle time and reducing costs.

Effective maintenance is crucial for consistent operation with minimal unexpected breakdowns. Implementing preventive checks and a well-structured maintenance plan can significantly reduce the likelihood of sudden failures, improving the machine’s overall health and efficiency.

The demand for skilled manpower to operate CNC machines is substantial. Frequent training for operators addresses this challenge. A culture of continuous training will empower existing personnel, enhance their confidence, and motivate them to perform at a higher level.

AI-driven predictive maintenance for CNC machines

Predictive maintenance means identifying failure before it occurs. AI-driven predictive maintenance combines the component life cycle and real-time machine monitoring. It delivers detailed predictive analyses about components’ estimated lifespans by closely tracking specific components. AI algorithms analyse sensor data streams, historical performance records, and real-time contextual information to forecast equipment degradation and potential failures.

By spotting early indicators of trouble, AI empowers maintenance teams to proactively schedule necessary repairs or replacements, significantly minimising unexpected downtime. AI-driven predictive maintenance offers the flexibility to dynamically adjust production schedules, reallocating tasks to alternative machines if a failure is anticipated, thus ensuring continuous operations. Ultimately, this approach can extend the operational life of equipment and lessen wear and tear.

————————————————————————————————————————

Prakash G – Director, Turning Centre Division of Ace Designers Limited.

Leading with an example

MSMEs are thus central to inclusive industrial growth in India. Ace Designers began as a small-scale CNC machine manufacturer, founded by visionaries Shirgurkar and Machado. Forty years ago, when local CNC production seemed improbable, they defied conventional norms and introduced cost-effective solutions. Their journey focuses on cultivating a strong vision and passion, staying customer-focused, identifying and addressing meaningful market gaps, and challenging the status quo with conviction are key.

Sustainable growth for MSMEs hinges on quality, cost competitiveness, financial discipline, and adherence to global standards. If a small-scale enterprise can navigate the initial few years with resilience and strategic focus, it can thrive and scale.

India’s growing demand for precision engineering can boost domestic production of high-precision CNC machines. We currently manufacture around 5,500+ CNC turning centres and 3,000+ machining centres annually, contributing to nearly a third of India’s machine tool output.

Achieving precision manufacturing requires access to advanced mother machines for component accuracy. We invest in high-end machinery, infrastructure modernisation, and talent development to meet global quality standards.

Beyond physical infrastructure, domain expertise is key. Application engineering, particularly mechatronics-based approaches, is gaining relevance. Indian institutions are increasingly offering programs in these disciplines. Our ‘Application Lab’ initiative complements this by nurturing skilled engineers and enabling practical problem-solving that is aligned with precision manufacturing needs.

Our strategic focus includes continuous workforce upskilling, adoption of global quality standards, and end-to-end design-to-manufacture alignment, all of which are geared toward building an Indigenous high-precision CNC ecosystem.

Ace Designers exports to over 20 countries and maintains offices in China, Europe, and Mexico. It has sold more than 2,000 machines in China alone.

Our strength lies in combining affordability with quality. We’ve established a dedicated Corporate Technology Group for focused R&D and technological advancement.

Innovation is a key priority. Through our in-house ‘Application Lab’, we conduct real-world testing to refine machine performance. We’re also actively ‘Indianising’ key technologies to make them locally relevant and cost-effective. Our investment in ‘Digital Twin’ capabilities allows us to simulate machine behaviour virtually, reducing the need for physical trials and accelerating time to market.

We collaborate with institutions like CMTI and IITs to co-develop cutting-edge, sustainable solutions. Our roadmap focuses on reducing the carbon footprint and optimising total cost of ownership (TCO).

Additionally, we are deeply engaged with IMTMA and other industry bodies, participating in policy and technology development forums. We are enhancing our supplier ecosystem to uplift component quality, ensuring our solutions remain competitive and globally benchmarked.

With these initiatives, we are confident that Indian CNC technology will compete globally within the next 2–3 years.

——————————————————————————————————————-

Nishant Agrawal – Manager Sales, Okuma India Pvt. Ltd.

Smarter CNC solutions for efficiency, savings, and growth

SMEs can manage the cost of CNC machines through various financing options such as bank loans, equipment leasing, government subsidies, or by investing in reliable pre-owned machines. To ensure better ROI, they should choose machines suited to their needs, train operators for efficient use, implement preventive maintenance, and integrate digital tools for productivity. Monitoring key performance indicators, optimising machine utilisation, and offering high-value services can improve returns and support long-term growth.

AI-driven predictive maintenance is revolutionising CNC machine operations by using real-time data to predict potential failures before they occur. This allows for timely maintenance, reduces unexpected breakdowns, extends machine life, and minimises downtime, resulting in more efficient and cost-effective production.

Future innovations in CNC machines will focus on deeper integration of AI and IoT to enable smarter automation, enhanced predictive maintenance, and improved human-machine interfaces. Advanced control systems will drive faster and more precise machining, while sustainable, energy-efficient designs will play a central role in the next generation of CNC technology.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.