Endless creation powered by energy

By Staff Report April 30, 2025 6:58 pm IST

The country is working towards its ambitious renewable energy target of 500 GW by 2030, including a mandate that at least 10% of this capacity must be backed by energy storage. With manufacturing taking the lion’s share of energy consumption, adopting new technologies that responsibly store and manage energy is imperative.

A vinyl pressing plant has reported producing about 14,000 records daily, utilising seven pressing machines that operate around the clock. Some large-scale producers can manufacture between 40,000 and 50,000 records each day. Michelin has reached impressive production levels of 100,000 tyres daily across its global plants, covering various sizes for consumer, commercial, and industrial vehicles.

Picture large production facilities tirelessly churning out products daily; such high production numbers would not be possible without the heavy, energy-consuming machinery in operation. The waste generated from production is directed toward recycling, which also relies on machinery, and ultimately, all operations hinge on a consistent energy supply. A day without energy at these facilities would result in significant losses for manufacturers. Therefore, storing and utilising energy effectively is crucial, necessitating new technology-integrated systems that prioritise energy conservation.

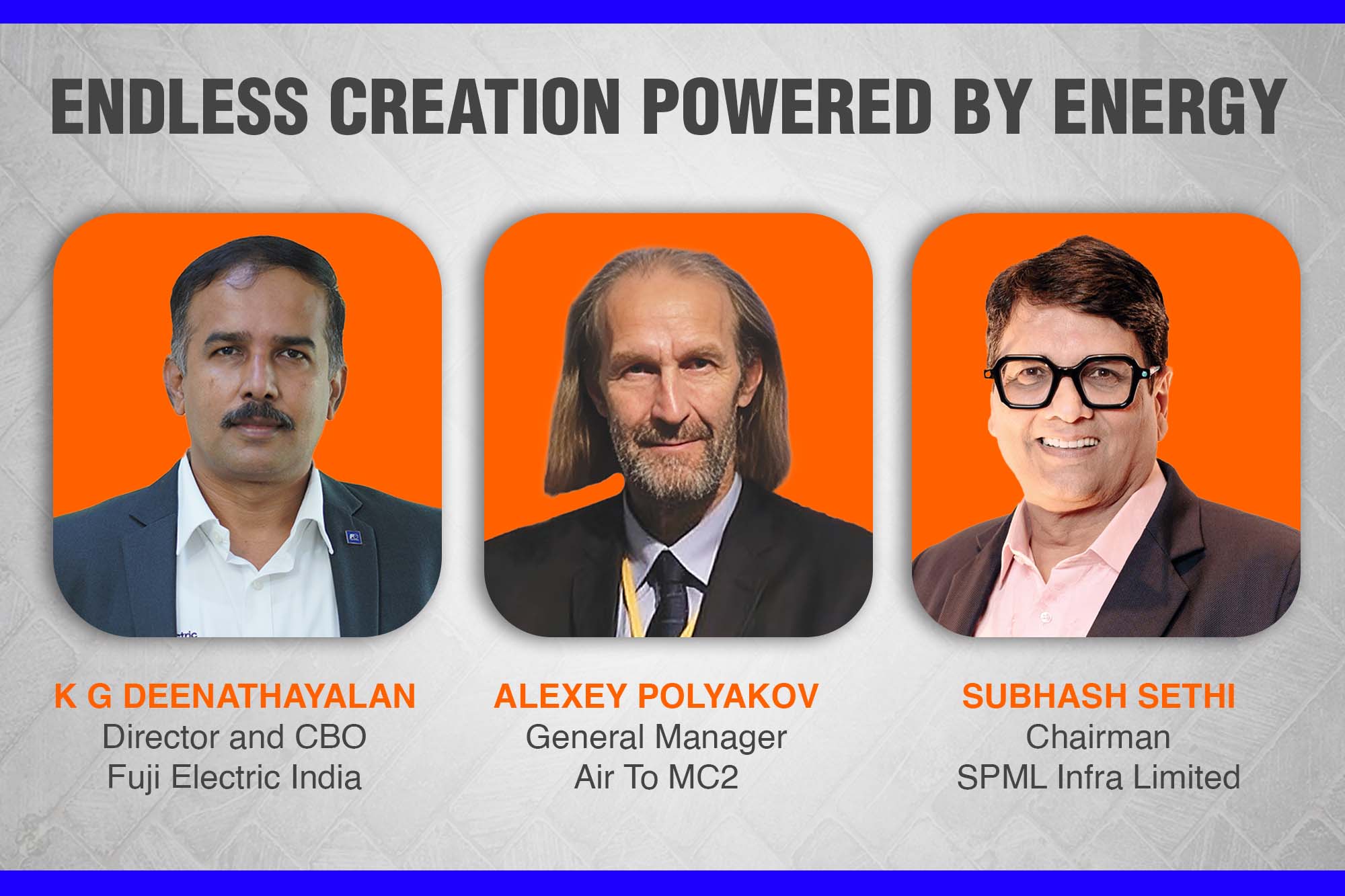

Energy storage and power management are part of a larger shift toward sustainable and resilient manufacturing. K G Deenathayalan, Director and CBO of Fuji Electric India, considers energy a strategic asset. Managing it well means reducing costs and improving productivity, stability, and compliance with environmental goals.

Fuji manufactures high-quality, reliable power modules tailored for various applications. These systems achieve a high power factor and low total harmonic distortion (THD), enhancing energy efficiency and reducing waste.

Deenathayalan shares that they operate in sectors where the cost of downtime or power quality issues can be very high, such as data centres, pharmaceuticals, automotive, and critical infrastructure. Due to this, they have made investments to scale up their 325,000 sq ft manufacturing space in Pune with fully automated lines to ensure operational efficiency, cost savings, and sustainability.

Manufacturing of the Energy Storage Solutions

The recent tariff policies announced by the Trump administration, mainly targeting Chinese imports into the US, can impact India’s growing battery and energy storage sector two-fold. According to a report, Subhash Sethi, Chairman of SPML Infra Limited, says the lithium-ferro-phosphate (LFP) market can be impacted since China produced 99% of LFP cells in 2024. There are also anti-dumping measures affecting the prices of anodes and energy storage systems.

Fluctuating global prices of key raw materials such as lithium and cobalt could increase production expenses. The disruptions may delay the ongoing downward trend in battery costs and limit short-term access to the latest innovations.

On the positive side, the tariffs could encourage global battery manufacturers to relocate their production to India, which has a strong domestic demand and favourable policies like the ease-of-business and production-linked incentive (PLI) scheme. This shift may open doors for more technology collaborations and quicker access to advanced battery innovations. Indian producers could also benefit from new export prospects to the US, as American buyers will seek reliable alternatives to Chinese suppliers.

Integration Challenges

Integrating renewable sources into traditional manufacturing setups involves more than just installing solar panels or wind turbines. The challenge lies in matching variable energy generation with the consistent or variations of power demands for manufacturing operations.

Many manufacturers are now adopting hybrid energy systems that combine solar, BESS, and diesel backup; all coordinated through an intelligent EMS.

Deenathayalan shares an example of a recent project with a textile manufacturer. BESS helped them align loom operations with solar generation during daylight hours while drawing from storage in the evening. This reduced their grid dependency by over 40 percent. Manufacturers are exploring microgrids that combine storage with solar and other distributed energy sources in some industrial zones where grid reliability is limited.

Latest developments for energy storage

The pace of innovation in energy storage is encouraging, especially as more industries commit to renewable energy targets. Lithium-ion batteries dominate due to their high energy density and falling costs. Alternatives like sodium-ion and flow batteries are drawing attention for long-duration storage and specific use cases.

Options like the Sunbird off-grid/hybrid, bidirectional solar inverter, and bidirectional inverter are also available. This solution is built specifically for solar-heavy industrial setups. It is designed to handle variable solar input while managing charging and discharging cycles. It is well-suited for applications with low grid reliability or where users want to reduce diesel generator dependency.BESS units are increasingly being deployed in hybrid and microgrid systems. These systems can store energy while improving power quality. With built-in functions for reactive power compensation, voltage stabilisation, and harmonics filtering, they are particularly effective in protecting sensitive manufacturing equipment.

Solid-state batteries are emerging as safer, higher-capacity alternatives for next-generation applications. Flow batteries, such as vanadium redox systems, offer long-duration storage with high safety and lifespan for large-scale operations. Meanwhile, sodium-ion batteries provide a cost-effective option for stationary energy storage in budget-conscious industries. Hydrogen energy storage is gaining traction, especially in decarbonisation efforts for long-term and high-capacity needs. Thermal energy storage (TES) enables efficient heat management in food processing and textiles, while compressed air energy storage (CAES) is suited for bulk storage. Second-life EV batteries also present a sustainable, low-cost option for non-critical manufacturing loads.

To complement these storage solutions, manufacturers are adopting smart energy management technologies. AI-based Energy Management Systems (EMS) provide real-time analytics and predictive insights for load optimisation and maintenance. Digital twins simulate plant energy profiles to test efficiency strategies, while IoT-based sensors detect real-time inefficiencies across machines and processes. Demand response systems help manage peak loads by adjusting consumption based on utility signals, often yielding financial incentives. Blockchain technology allows for secure, traceable energy transactions within industrial ecosystems. Microgrids and localised on-site networks integrate various energy sources to boost resilience, autonomy, and cost-efficiency, making them valuable assets for future-ready manufacturing.

Alexey Polyakov, General Manager of Air To MC2, also recommends the Maisotsenko Cycle (M-Cycle), which introduces five key thermodynamic innovations—Wet Combustion, Inlet Cooling, Phase Change of Working Substance, Waste Heat Recovery, and High Enthalpy at Low Temperature—making it one of the most efficient and affordable ways to convert heat into mechanical or electrical energy. Wet Combustion significantly reduces NOx emissions by 10x and CO effluents by 2X while doubling thermal efficiency in manufacturing. Inlet Cooling helps increase gas turbine output by up to 25% in hot weather by cooling intake air below the wet bulb temperature. Waste Heat Recovery through the M-Cycle uses enhanced humidification to maximise energy reuse and improve overall system efficiency. The M-Power Cycle builds on these principles to deliver high thermal efficiency using renewable air energy, with minimal design changes to existing power systems. This makes the M-Cycle an innovative and sustainable energy management solution for manufacturers focused on reducing emissions and improving energy use.

Policies and government initiatives

Government policies are making energy storage more viable for the Indian industry. The Production Linked Incentive (PLI) scheme for Advanced Chemistry Cells encourages local battery manufacturing, and the government is passing on solar panel manufacturing, which helps reduce import dependence and brings down system costs over time. This supports the reduction of BESS costs for the customers.

The National Energy Storage Mission (NESM) and the draft National Energy Storage Framework provide a much-needed roadmap for industry and utilities to deploy storage systems. Viability Gap Funding (VGF) addresses cost concerns and makes investing in large-scale battery energy storage projects easier for businesses.

The Energy Storage Obligation (ESO) requires utilities to procure a share of their power from renewables supported by storage, which improves the overall ecosystem. Interest is also building through pilot projects from SECI and NTPC, and policies related to green hydrogen and solar-wind hybrid models are further reinforcing the role of storage.

—————————————————————————————-

“As manufacturing evolves toward smarter and greener operations, energy storage and management have become foundational to future-proof industrial growth against energy volatility and sustainability mandates.”

K G Deenathayalan, Director and CBO, Fuji Electric India

“The Maisotsenko Cycle can greatly help industrial energy production by offering a pathway to ultra-efficient, low-emission power generation by turning waste heat into a strategic asset and scaling sustainable manufacturing.”

Alexey Polyakov, General Manager of Air To MC2

“India is committed to all 17 SDGs, particularly SDG-7 , for affordable, sustainable energy. It has electrified all villages, expanded renewable energy, and promoted clean energy policies. Additionally, under SDG-6, India aims to provide clean drinking water for all by 2030, showcasing its dedication to sustainable development and leadership in the clean energy transition.”

Subhash Sethi, Chairman of SPML Infra Limited

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.